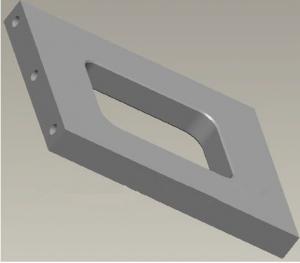

OEM Metal Auto Parts Stamping Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1.FOB:US$100~800/set

2.MOQ:1SET

3.Supply Ability:100set/month

4.ISO9001/TS16949:2009

5.Material: Rubber

Plastic Injection Mould, Plastic Mould:

Meet your "short delivery time", "high precision", "good quality", "low price" request for mould making service

1.CAD/CAE/CAM computer-aided design, simulation, manufacturing integration

2. High-quality materials to meet good quality

3. Application of advanced equipment in mould making to meet high precision

4. Application of advanced surface treatment technology to improve the life of the mould

5. High-speed milling technology significantly improve the mould processing efficiency

6. OEM and ODM are all both avaliable.

The most favorable quote:

1, Give more benefit to our clients in exchange of long-term cooperation.

2, Provide free mould accessories and parts during the mould lifetime.

Advantages:

1, ISO9001/TS16949:2009 certified.strict quality control system and methods

2, Own lots of experienced engineers and responsible skilled workers.

3, Offer one-stop solution from design drawing to finished products.

4, OEM and ODM are both available.customer first.on-time delivery.

5, Carry out strict cost control system and efficient production line.

6, Sincerely care every order.cherish the co-operation opportunity.

7, Lifetime technology support and consultancy.

- Q: Can olive nets be used for urban olive trees?

- Yes, olive nets can be used for urban olive trees. These nets are commonly used to protect the fruit from birds and other pests. They can be a practical solution for urban environments where space is limited and the trees are in close proximity to buildings or other structures. Additionally, olive nets can help to prevent fallen olives from creating a mess on sidewalks and streets, making them suitable for urban olive tree cultivation.

- Q: Can olive nets be used in hilly or sloping terrains?

- Yes, olive nets can be used in hilly or sloping terrains. The nets can be secured or anchored to the ground to prevent them from sliding or moving on the slopes. This helps to protect the olives from rolling down the hill and ensures efficient harvesting.

- Q: Can olive nets be used for both young and mature olive trees?

- Yes, olive nets can be used for both young and mature olive trees. Olive nets are commonly used to protect the olives from birds and other pests during the harvesting season. They can be easily installed and removed, making them suitable for use on both young and mature olive trees.

- Q: Do plastic products contain toxic substances?

- Plastic products for daily use are not toxic, and paper, paper no poison, but the papermaking process will produce pollution, and the use of some toxic substances. Toxic part of manufacturing plastic raw materials, plastic products but is a polymer material, not toxic, but does not rule out some unscrupulous businessmen in the plastic material or add some excess recovery assistant.

- Q: What is an olive net?

- An olive net is a type of netting used in olive orchards to catch the olives as they fall from the trees during harvesting.

- Q: Do olive nets affect the shelf life of the olives?

- Yes, olive nets can affect the shelf life of olives. Olive nets are used to protect olives from pests, birds, and other external factors during the growth and ripening process. However, if not properly managed, these nets can trap moisture, which can lead to increased humidity and create a favorable environment for the growth of bacteria and mold. This can ultimately decrease the shelf life of the olives if not addressed promptly.

- Q: Can olive nets be used in areas with heavy rain?

- Yes, olive nets can be used in areas with heavy rain. Olive nets are designed to protect the olive trees and catch the falling olives during harvest. They are typically made of durable materials that can withstand various weather conditions, including heavy rain. However, it is essential to ensure proper installation and maintenance to prevent water pooling or excessive weight on the nets, which could potentially cause damage.

- Q: Can olive nets be used in olive groves with limited access to roads?

- Yes, olive nets can be used in olive groves with limited access to roads. Olive nets are typically lightweight and easy to transport, making them suitable for areas with limited road access. They can be carried by hand or using alternative modes of transport such as small vehicles or even by foot. Additionally, olive nets are designed to be easily installed and removed, allowing for efficient harvesting even in remote or hard-to-reach locations.

- Q: How do olive nets prevent damage from fruit fly infestations?

- Olive nets prevent damage from fruit fly infestations by acting as a physical barrier, preventing the flies from reaching the olive fruits and laying eggs on them. The tightly woven nets cover the trees, creating a barrier that blocks the entry of fruit flies while still allowing sunlight and air to reach the fruit. This reduces the chances of infestation and protects the olives from damage, ensuring a higher yield and quality harvest.

- Q: Can olive nets be used in organic farming?

- Yes, olive nets can be used in organic farming. Olive nets are commonly used in organic farming practices to protect olive trees from pests and birds without the use of chemical pesticides. These nets create a physical barrier, preventing pests from accessing the trees and damaging the fruits. Additionally, olive nets help to collect fallen olives, making it easier to gather them for processing while maintaining organic farming principles.

1. Manufacturer Overview

| Location | Sichuan,China |

| Year Established | 2006 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2000;ISO/TS 16949 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Chongqing,Shanghai,Shenzhen |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

OEM Metal Auto Parts Stamping Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords