OEM Precise Compression Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 500 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

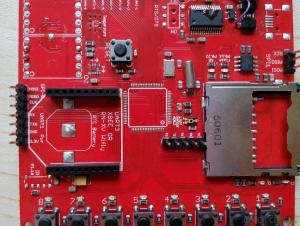

Detailed Product Description

1.FOB:US$100~800/set

2.MOQ:1SET

3.Supply Ability:500set/month

4.Quality::ISO9001/TS16949:2009

5.Product Material: steel

Meet your "short delivery time", "high precision", "good quality", "low price" request for mould making service

1. CAD/CAE/CAM computer-aided design, simulation, manufacturing integration

2. High-quality materials to meet good quality

3. Application of advanced equipment in mould making to meet high precision

4. Application of advanced surface treatment technology to improve the life of the mould

5. High-speed milling technology significantly improve the mould processing efficiency

The most favorable quote:

1, Give more benefit to our clients in exchange of long-term cooperation.

2, Provide free mould accessories and parts during the mould lifetime.

Advantages:

1, ISO9001/TS16949:2009 certified. strict quality control system and methods

2, Own lots of experienced engineers and responsible skilled workers.

3, Offer one-stop solution from design drawing to finished products.

4, OEM and ODM are both available. customer first. on-time delivery.

5, Carry out strict cost control system and efficient production line.

6, Sincerely care every order. cherish the co-operation opportunity.

7, Lifetime technology support and consultancy.

- Q: What are the benefits of plastic bags? What's the disadvantage?

- Advantages of plastic bags: the invention of plastic bags brings convenience and sanitary life for human beings. The emergence of plastic bags will also reduce food waste, the nature of the fungusproof mold also protected the health of human beings, plastic bags are used instead of other packaging materials such as paper, glass, cans, etc., to reduce energy loss;

- Q: What glue does it stick to plastic?

- If it is small things glued to the plastic parts, you can use 502 of the quick drying glue. If the whole piece of plastic cracking, such as bumpers, to the car repair shop burning plastic welding, because the car wash plastic products have a certain thickness, the general speed drying glue even if stuck, but not force.

- Q: What is the lifespan of an olive net?

- The lifespan of an olive net can vary depending on various factors such as the quality of the net, the frequency of use, and the overall care and maintenance. However, on average, a well-maintained olive net can last for several years, typically ranging from 3 to 5 years.

- Q: Plastic products 2 can hold hot things?

- The dangers of indiscriminate use of plastic products to hold food seem to have aroused the attention of people and society. We should absorb the experiences and lessons of the United States in 70s and early 80s, Americans are widely used in plastic packaging and storage of food, especially food packaging, but at the end of 80s has found its harm, has been gradually reducing the use of plastic packaging cooked food and other food, but instead of using specially disinfected paper packaging.

- Q: What's the difference between memory plastic and sheet metal?

- Ingredients: most of the ingredients are acetate fibers, and a few high-grade frames are fibers of propionic acid. The cellulose fiber sheet is divided into injection molding and compression grinding type, injection molding, as the name suggests, is watered by the mold, but most of the current press polishing processing plate glasses. On the origin of the plate, France and Italy plate is better, and Japan is also relatively good, many of the high grade plate glasses are based on these high-quality plates, and therefore more trustworthy quality. Design: designed for the general public and the pursuit of quality of life students tailor-made. Features: simple, introverted design style, the overall show of a sedate side, using the right coloring process. Emphasize stereoscopic changes in the mirror's leg line.

- Q: How do olive nets affect the overall flavor of the olives?

- Olive nets do not directly affect the overall flavor of the olives. The primary purpose of olive nets is to prevent the olives from falling to the ground during harvesting, ensuring their quality and reducing potential damage. The flavor of olives is primarily influenced by factors such as the olive variety, ripeness, growing conditions, and processing methods.

- Q: What are the raw materials used in the production of plastic products?

- Bearing cleaning supplies, plastic containers and bath products currently used in supermarkets and shopping malls in the plastic bag is made of this material, can resist high temperature of 110 DEG C, indicating the food use of plastic bags can be used for holding food. Bearing cleaning supplies, plastic containers and bath products can be repeatedly used carefully after cleaning, but these containers are usually not good cleaning, easy residual cleaning supplies, become a breeding ground for bacteria, it is better not to use circulation cleaning is not thorough so.

- Q: Do olive nets require any special installation techniques for espaliered trees?

- Yes, olive nets do require special installation techniques for espaliered trees. Espaliered trees have a specific pruning and training method where they are grown flat against a wall or trellis, creating a two-dimensional shape. When using olive nets on espaliered trees, it is important to carefully attach the nets to the support structure, ensuring that the branches and foliage are properly enclosed. This can be achieved by using clips, ties, or hooks designed for espaliered trees. Proper installation techniques will help protect the olives from birds and other pests while maintaining the desired shape of the tree.

- Q: Can olive nets be used in hilly or sloped olive groves?

- Yes, olive nets can be used in hilly or sloped olive groves. These nets are designed to be versatile and can be adjusted to fit different terrains. They can effectively catch olives on slopes and prevent them from rolling away, making harvesting easier and more efficient.

- Q: Can olive nets be used to reduce nutrient deficiencies?

- No, olive nets are primarily used for harvesting olives and do not have any direct impact on reducing nutrient deficiencies. Nutrient deficiencies are typically addressed through dietary changes, supplementation, or fortified food products.

1. Manufacturer Overview

| Location | Sichuan,China |

| Year Established | 2006 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2000;ISO/TS 16949 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Chongqing,Shanghai,Shenzhen |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

OEM Precise Compression Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 500 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords