Light Industrial Healthy PVC/PU/PE Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Industrial Healthy PVC/PU/PE Conveyor Belt

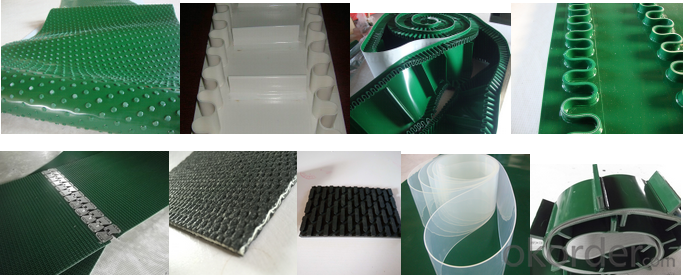

PVC Conveyor Belt

PVC conveyor belt has good elasticity ,not easy to be deformed . It is widely used in good , tobacco , logistics , packaging and other industries . Applicable to coal mine underground transportation ,also can be used in metallurgy ,chemical idustry material handling .

Applications & features:

It is widely used in the assembly lines in the areas of food processing, pharmaceutical, electronics, cigarette, printing

Product features: hard wearing, good tensile strength, long service life.

Product specification: One fabric- One rubberized, Two fabric- Two rubberized, Three fabric- three rubberized,ect

Forms of joints: tooth-shaped, stepped&angled, or metal buckle

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

Packaging & Shipping

1.Free for samples, Door-to-Door.

2. By Air or by Sea for batch goods, Airport/ Port receiving.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:Based on customers' quantity. In general,25 days for batch goods.

Product photos:

Pls contact me freely if any inquiry,thank you!

- Q:Can olive nets be used for olive tree erosion control?

- Yes, olive nets can be used for olive tree erosion control. These nets are typically placed on the ground around the base of the tree to prevent soil erosion caused by water runoff. They help retain soil and moisture, protecting the roots of the olive tree and reducing erosion.

- Q:How do olive nets prevent damage from heavy machinery during harvesting?

- Olive nets prevent damage from heavy machinery during harvesting by creating a protective barrier between the machinery and the ground. The nets are spread out beneath the olive trees, catching the falling olives and preventing them from hitting the ground directly. This helps to reduce impact and potential damage caused by the machinery's weight or movement, ensuring a safer and more efficient harvesting process.

- Q:Can olive nets be used to reduce soil erosion?

- Yes, olive nets can be used to reduce soil erosion. Olive nets are often used in olive orchards to catch fallen olives during harvest, but they also serve as an effective method to prevent soil erosion. These nets act as a physical barrier, preventing soil particles from being washed away by rainwater or blown away by wind. By keeping the soil in place, olive nets help maintain soil fertility, prevent loss of topsoil, and promote healthy plant growth.

- Q:How do olive nets affect pollination?

- Olive nets can have a negative impact on pollination as they prevent insects and other pollinators from accessing the flowers, thereby reducing the chances of successful pollination and fruit set.

- Q:How do olive nets prevent damage from wind-blown debris?

- Olive nets prevent damage from wind-blown debris by acting as a protective barrier, catching and trapping the debris before it reaches the olives. The nets are designed to be durable and tightly woven, ensuring that even small debris particles cannot pass through. This helps to safeguard the olives and prevent any potential damage or contamination caused by the debris.

- Q:Can olive nets be used in combination with soil erosion prevention techniques?

- Yes, olive nets can be used in combination with soil erosion prevention techniques. Olive nets, also known as erosion control blankets, can help prevent soil erosion by providing a protective layer over the soil surface. They can be used in conjunction with other erosion prevention techniques such as mulching, terracing, contouring, and planting of ground cover crops. The nets help to stabilize the soil, reduce water runoff, and promote vegetation growth, all of which contribute to preventing soil erosion.

- Q:What is the white fine plastic rope hanging with a tag on it?

- The white, thin plastic rope hanging from the coat is called a nylon rope.

- Q:Can olive nets be used for olive trees in arid regions?

- Yes, olive nets can be used for olive trees in arid regions. These nets provide shade and reduce water evaporation, helping to conserve moisture in the soil and protect the olive trees from excessive heat and sun exposure. Additionally, they can prevent birds from damaging or consuming the olives, ensuring a higher yield in arid regions where water resources may be limited.

- Q:How do olive nets help in reducing the risk of root diseases?

- Olive nets help in reducing the risk of root diseases by providing a protective barrier around the tree roots. These nets prevent soil erosion and reduce the likelihood of pathogens infecting the roots. Additionally, olive nets help maintain a stable soil temperature and moisture level, creating a favorable environment for root growth and minimizing stress on the tree.

- Q:How to make plastic products soft?

- This is actually very simple, you can put him in the heating on a small would like or use hot water but this is useful if you want to be a short time long time it is very difficult because the weather is cold now, so it is hard to soft the other day will be better if you don't is not how love feeling if I still advise you to buy a good very soft

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Industrial Healthy PVC/PU/PE Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords