Food Grade White/Blue/Green PVC/PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FOOD GRADE WHITE/BLUE/GREEN PVC/PU CONVEYOR BELT

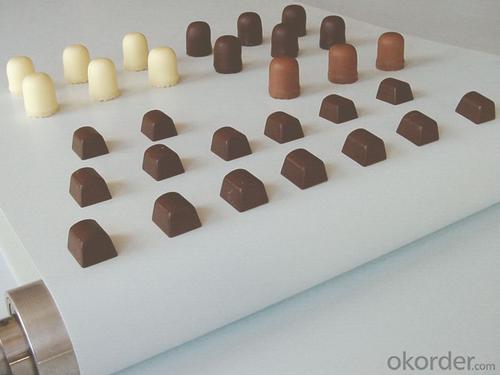

Light Duty Conveyor Belts for food industry are excellent resistant to oil and fat, non-toxic, healthy and easy to clean. The type of belts conforms with FDA, USDA and EU regulations, can be used in many applications in the following industries: bakery, confectionary, meat and poultry, fish, fruit and vegetables, dairy, agriculture etc.

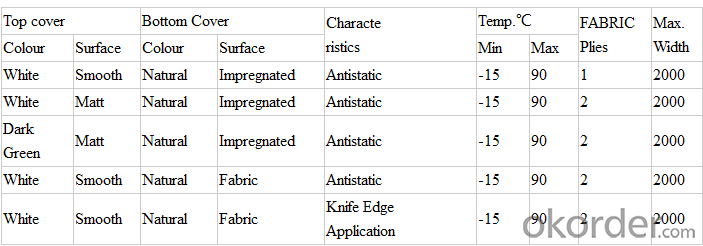

PVC/PU conveyor belt/FDA

1. material: PVC/PU

2. color: white,dark green,sky bule,etc

3. surface: smooth,matt

Description:

Conveyor belt is widely used in conveyor system. Trans mission system processiry systemand Packaging conveyor ect.it has many Variety like mesh conveyor belt .

metal conveyor belt .PVC conveyor belt .Conveyor belt with skirt sidewall.hole belt.

Flat Slat POM belt. Lattice POM belt.Hard conveyor Belt.

Specification:

1.Belt curves are developed by our company has the domestic advanced technology level of quality .

2.products.Whether driven tensioning tapered roller precision machining, or the fan belt anti-deviation

adjustment

3.techniquesare reflected in the technical and process my company on the lead position.

4.Turning belt can be made into 90 °, 180 ° or even user needs at any angle. The turning radius according to the size and weight of the object conveyor may be designed to 300MM/600MM/900MM/1200MM/1500MM/2000MM/3000MM other specifications.

5.Curve conveyor belt with the straight line, to achieve the perfect

angle transporting goods during transport can maintain its relative position

synchronized conveyor. Particularly for use in the delivery of irregular items,

such as bags, bulk, small parts.

Working environment:

1. the working environment, conditions and conditions

2.Need to consider the time of day every day operation, the operating frequency, the service life of the belt conveyor, feeding and unloading methods.

3.Work environment, conditions: ambient temperature, outdoor or indoor, environmental requirements, mobile or fixed, telescopic requirements.

Product Photos

For more informations,please contact us freely,thank you.

- Q: Are there any maintenance tips for olive nets during the off-season?

- Yes, there are a few maintenance tips for olive nets during the off-season. Firstly, make sure to clean the nets thoroughly before storing them to remove any dirt, debris, or olive residue. This will prevent the growth of mold or mildew. Additionally, check for any damages or tears in the nets and repair them if necessary to ensure they are in good condition for the next harvest season. Properly store the nets in a dry and well-ventilated area to prevent any moisture buildup.

- Q: Can olive nets be used in both traditional and modern olive farming practices?

- Yes, olive nets can be used in both traditional and modern olive farming practices. Olive nets are versatile and can be used to protect the olives from birds and other pests, as well as to collect the olives during the harvest. They are commonly used in traditional farming methods where olives are hand-picked, as well as in modern practices where mechanized harvesting is employed. The use of olive nets helps to ensure a successful and efficient olive harvest regardless of the farming techniques employed.

- Q: Can olive nets be used to improve overall orchard efficiency?

- Yes, olive nets can be used to improve overall orchard efficiency. These nets help in reducing fruit drop, protecting the olives from pests and birds, and ensuring a higher yield. They also provide shade, which can help in preventing sunburn on the fruit. Overall, the use of olive nets can enhance orchard management and increase productivity.

- Q: Are olive nets easy to handle?

- Yes, olive nets are relatively easy to handle. They are lightweight and flexible, making them simple to install and remove. Additionally, they can be easily folded and stored when not in use.

- Q: Do olive nets require any special maintenance during the off-season?

- Yes, olive nets require proper maintenance during the off-season. It is recommended to clean and store them properly to ensure their longevity. This can involve removing any debris or leaves trapped in the netting, gently washing them, and storing them in a dry place to prevent mold or damage. Additionally, regular inspection for any damages or wear is essential to address any issues before the next season.

- Q: How do olive nets affect air circulation in the orchard?

- Olive nets can impede air circulation in the orchard.

- Q: Can olive nets be used to extend the harvesting season?

- Yes, olive nets can be used to extend the harvesting season. These nets are commonly used in olive orchards to collect fallen olives during mechanical harvesting or to protect ripe olives from birds, thus prolonging the period in which olives can be harvested.

- Q: Do all plastics have plasticizers?

- There are many kinds of plasticizers and only a few of them are toxic. The key is to see whether the manufacturer of the product you have has a conscience, and whether the authorities concerned have done anything about it.

- Q: Can olive nets be used for olive tree pollination management?

- No, olive nets are not used for olive tree pollination management. Olive trees are wind-pollinated, meaning they do not rely on insects or other pollinators for pollination. Therefore, olive nets are typically used for harvesting purposes to collect the fallen olives or to protect the crop from birds.

- Q: Can olive nets be used in both small and large-scale olive farms?

- Yes, olive nets can be used in both small and large-scale olive farms. The nets are designed to protect the olives from birds, pests, and harsh weather conditions, regardless of the size of the farm. They are adjustable and can be easily installed in various configurations to cover the olive trees efficiently, making them suitable for both small-scale and large-scale farming operations.

Send your message to us

Food Grade White/Blue/Green PVC/PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords