White Polyurethane/PU Food Grade Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Polyurethane/PU Food Grade Conveyor Belt

PU Conveyor Belt

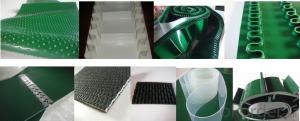

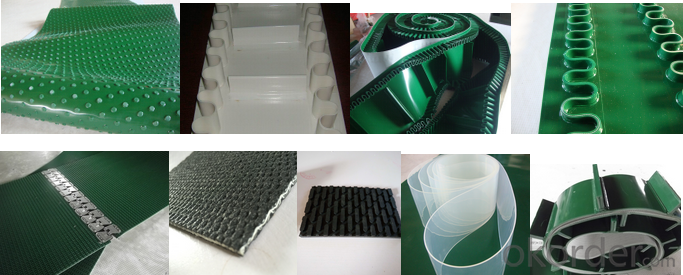

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Please contact us freely if you need any conveyor belt.

- Q: How is the recycling of plastic bottles handled?

- Plastic bottles melt, melt, dissolve, make unsaturated resins, or re - granulate, but if they are made of transparent products, they can easily be found to be opaque and have poor light transmitting particles.Polyethylene propertyPolyethylene is odorless, non-toxic, feel like wax, has excellent resistance to low temperature performance (minimum temperature can reach -70 ~ -100 C), good chemical stability, erosion resistance to most acid-base (not resistant to oxidizing acid), insoluble in common solvents at room temperature, low water absorption, excellent electrical insulation properties; but polyethylene for environmental stress (chemical and mechanical function) is very sensitive, heat aging resistance difference.The properties of polyethylene vary depending on the molecular structure and density.Mainly used in the manufacture of films, containers, pipes, monofilament, wires, cables, daily necessities, etc., and can be used as television, radar and other high-frequency insulation materials.

- Q: What are the hazards of plastic oiler

- Need to see what kind of plastic to fill the oil, at room temperature, PET plastic pot of oil is non-toxic, but other plastics in the oil will generally precipitate some chemicals.

- Q: Can olive nets be used on olive trees grown in cold climates?

- Yes, olive nets can be used on olive trees grown in cold climates. Olive nets are primarily used to protect the olive fruits from birds and other pests, regardless of the climate. However, it is important to consider other factors such as winter hardiness of the olive tree variety and appropriate winter protection methods to ensure the tree's survival in cold climates.

- Q: Can olive nets be used for table olive production?

- Yes, olive nets can be used for table olive production. These nets are commonly used to protect the olives from birds and other animals, as well as to collect the olives during harvesting. By using olive nets, the olives can be kept clean and free from damage, ensuring higher quality table olive production.

- Q: How do olive nets prevent damage from birds and other animals?

- Olive nets prevent damage from birds and other animals by creating a physical barrier that prevents them from accessing the olive trees. The tightly woven mesh of the nets acts as a shield, preventing birds from reaching the olives to eat or peck at them. Additionally, the nets also deter other animals, such as squirrels or rabbits, from climbing the trees and causing damage. Overall, olive nets provide an effective means of protecting the olives and ensuring a successful harvest.

- Q: Are olive nets fire-resistant?

- Yes, olive nets are typically fire-resistant. They are designed to protect olive trees from fires and are made from durable materials that can withstand heat and flames.

- Q: What are the raw materials used in the production of plastic products?

- The poisonous and harmful substances produced by plastics of this kind of material come from 2 aspects. One is the single molecule vinyl chloride which is not completely polymerized in the process of production, and the other is the harmful substance in the plasticizer (two). These 2 substances in the high temperature and fat when easy to precipitate, toxic substances enter the human body with food, easy to cause cancer. At present, the containers for this material are less used for packaged food. If the family has this kind of material, don't let it heat.

- Q: Are there any other plastic products besides stretch?

- When the external force (hammer or rolling) function can crush into sheets without rupture is called ductility. Such as ductility of metal, including gold, platinum, copper, silver, tungsten and aluminum are rich in ductility. Quartz, glass and other non-metallic materials have some ductility at high temperature. Ductility is a property of metal minerals, one under external force characteristics of metal mineral is key to produce plastic deformation, which means that the mobile ions can rearrange and lose cohesion, which is the root cause of metal bond minerals with ductility.

- Q: Do olive nets require any specific labeling or certification?

- Yes, olive nets may require specific labeling or certification depending on the country or region where they are used. This is to ensure that the nets meet certain quality and safety standards, and to provide information about their origin, material, and other relevant specifications. It is advisable to consult local regulations or industry standards to determine the specific labeling or certification requirements for olive nets in a particular area.

- Q: How many kinds of plastics are there?

- PU Name: polyurethane (foam). Mainly used for handrail accessories.Name: POM steel is mainly used for wear parts such as mats, casters, door hinge, hinge and so on. The performance of wear resistance, pressure resistance, but poor dimensional stability.Name: PA nylon. Mainly used as foot, claw, wheel wear, the life of high demand place. Features: wear resistance, pressure resistance, high strength and long service life of indoor, individual models such as PA66 heat up to 2200, is easy to change, easy to break the drying performance, poor weather resistance in the sun.

Send your message to us

White Polyurethane/PU Food Grade Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords