White PU Conveyor Belt Food Grade Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Processing Conveyor Belt

Food Processing Conveyor Belt Introduction

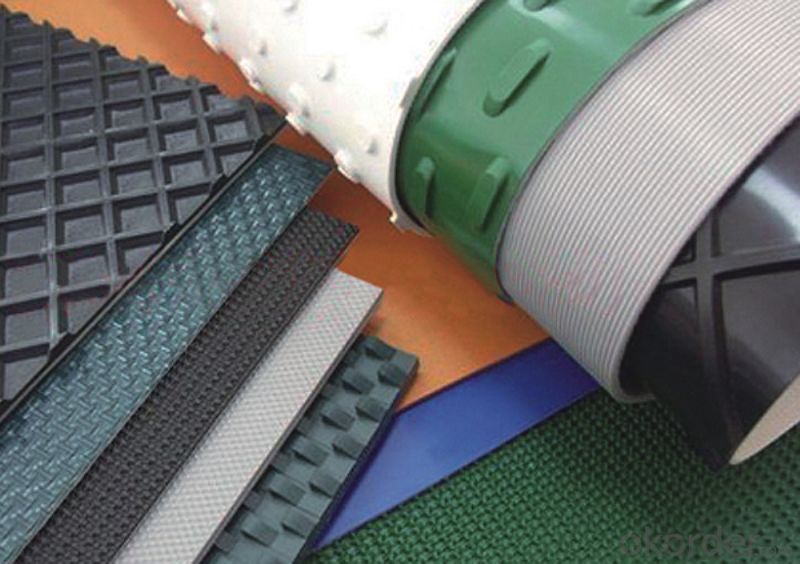

Food processing conveyor belt choose high quality high strength polyester fabric are the core, coated with PU or PVC as loading surface. With advantages of good flexibility, material environmental friendly, light duty, high tensile strength, anti oil, easy learning, our food processing conveyor belt meet EU and USA market requirements.

Food Processing Conveyor Belt Application

Food processing conveyor belt is widely used in food industry, such as vegetables, snack food, beer, sea food, etc.

Food Processing Conveyor Belt Advantage

Food processing conveyor belt is made of harmless material, no toxicity, no smell, anti-oil, easy cleaning, high tensile strength, good flexibility, light weight, solid and durable.

Food Processing Conveyor Belt Specifications

Total thickness(mm) 0.8~5.0 | Top coating hardness( Shore A) 55~92 |

Total weight(kg/m2) 0.9~5.4 | Belt tension 1% elongation(N/mm) 5~ 30 |

Minimum production width(mm) 15~180 | Working temperature range(℃) -20/+90 |

Type of support R=expansion cylinder, S=flat, T=groove shape | Max production width(mm) 3000 |

Lateral stability Yes | Food grade Yes |

Low noise | Fire resistance |

Surface antis tatic |

Food Processing Conveyor Belt Photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

Quality is the first priority, we have strict quality control system.

1) All raw material we used are environmental freindly

2) Quality Control Department specially responsible for quality checking in each process. We make testing on incoming raw material and finished products. Your third party testing is also welcomed.

3) Skillful workers care every details in handling the producing and packing processes.

Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Are olive nets compatible with mechanical olive harvesters?

- Yes, olive nets are compatible with mechanical olive harvesters. Olive nets are commonly used in conjunction with mechanical harvesters to catch and collect the olives as they are shaken off the trees. The nets are spread beneath the trees to ensure that the olives fall onto them, making it easier for the mechanical harvesters to efficiently collect and separate the olives from other debris.

- Q: What are the main features of plastics?

- Plastic is a kind of synthetic polymer with plasticity. With synthetic rubber and synthetic fiber, it has become the three most important synthetic materials in daily life.

- Q: Can olive nets be used for both mechanical and hand harvesting?

- Yes, olive nets can be used for both mechanical and hand harvesting.

- Q: Do olive nets affect the quality of harvested olives?

- Yes, olive nets can affect the quality of harvested olives. While they serve the purpose of preventing olives from falling to the ground and potentially getting damaged or contaminated, improper use of nets or leaving olives on the tree for too long can lead to overripe or spoiled olives. Additionally, if the nets are not properly cleaned and maintained, it can result in mold or fungal growth on the olives, affecting their quality. Therefore, it is important to use olive nets correctly and harvest the olives at the appropriate time to ensure optimal quality.

- Q: How does an olive net affect the overall crop health in the olive grove?

- An olive net can have both positive and negative effects on the overall crop health in an olive grove. On one hand, it can provide protection against pests and birds, reducing the risk of damage to the olives and improving the yield. Additionally, the net can create a microclimate that helps retain moisture in the soil, promoting healthier growth and reducing water stress. On the other hand, if not properly installed or maintained, the net can hinder air circulation, leading to increased humidity and potentially causing fungal diseases or reduced fruit quality. Therefore, it is essential to carefully assess the net's installation, maintenance, and the specific needs of the olive grove to ensure its positive impact on crop health.

- Q: Plastic products after melting, dip in the pot bottom, how to remove?

- It melted with fire. I suggest you use bamboo brush later. I don't think the plastic is good

- Q: How do you store olive nets during the off-season?

- During the off-season, olive nets should be properly cleaned and dried before storing them in a cool and dry place. It is recommended to fold them neatly and store them in airtight containers or bags to protect them from dust and pests. Additionally, it is important to ensure that the nets are stored away from direct sunlight to prevent any damage or deterioration.

- Q: How do olive nets affect pollination?

- Olive nets can have a negative impact on pollination as they prevent insects and other pollinators from accessing the flowers, thereby reducing the chances of successful pollination and fruit set.

- Q: Do all plastic products taste?

- In the life of commonly used plastic polyethylene (used for making plastic wrap, bags, cups, pearl cotton, this is the most secure plastic products, no toxicity); (polyvinyl chloride pipes, packaging bags and other plastic products used in the production of PVC, is not toxic, but is in high temperature or other extreme conditions may release toxic hydrogen chloride);

- Q: What is the role of calcium carbonate in plastics?

- Improving the dimensional stability of plastic productsThe addition of calcium carbonate plays a skeleton role in plastic products, and has a great effect on the stability of plastic product size.

Send your message to us

White PU Conveyor Belt Food Grade Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords