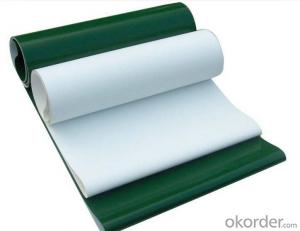

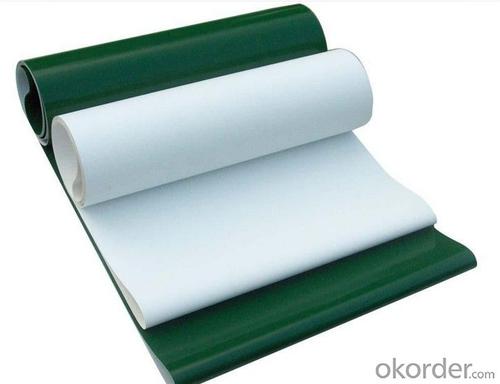

White Food Grade PVC PU Conveyor Belt 1.6mm 1.8mm 2.0mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Food Grade PVC PU Conveyor Belt 1.6mm 1.8mm 2.0mm

PVC conveyor belt,PU conveyor belt

Conveyor belt fabric layers:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

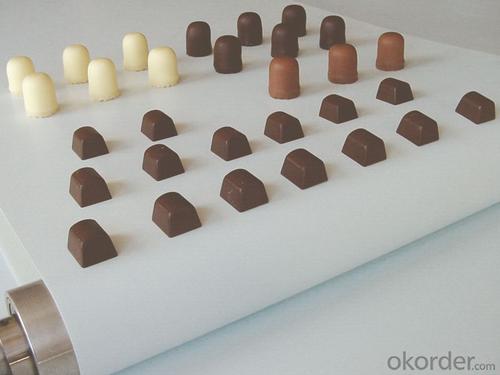

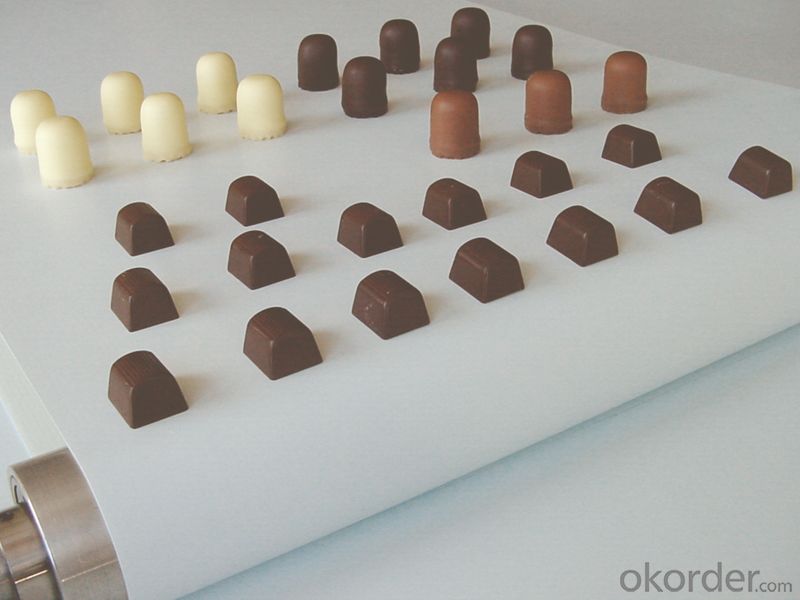

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

Product pictures:

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: How do you prevent olive nets from causing damage to nearby structures or buildings?

- One effective way to prevent olive nets from causing damage to nearby structures or buildings is by installing a protective barrier or padding between the net and the structure. This can be done by using foam or similar materials to create a cushioning layer that absorbs any impact and prevents direct contact between the net and the structures. Additionally, regularly inspecting and maintaining the nets for any signs of wear or damage can help identify potential issues early on and mitigate any risks.

- Q: Do olive nets protect against hailstorms?

- Olive nets are primarily designed to protect olives from birds and other pests, so they are not specifically designed to protect against hailstorms. While they may offer some level of protection against small hailstones, they are typically not effective in preventing damage from severe hailstorms.

- Q: How do olive nets prevent fruit theft in the orchard?

- Olive nets prevent fruit theft in the orchard by creating a physical barrier between the fruit and potential thieves. These nets are placed over the trees, covering the entire canopy, and secured tightly to prevent any gaps or openings. This prevents unauthorized access to the fruit, making it difficult for thieves to steal the olives without removing the netting first, which is time-consuming and raises the risk of detection.

- Q: Can olive nets be used for olive trees in urban settings?

- Yes, olive nets can be used for olive trees in urban settings. Olive nets are designed to protect the olives from birds and other pests, and they can be used in any location where olive trees are grown, including urban areas.

- Q: Can olive nets be used for both young and mature olive trees?

- Yes, olive nets can be used for both young and mature olive trees. Olive nets are typically used to protect the crop from birds and to collect the fallen olives during harvesting. Both young and mature olive trees can benefit from the use of olive nets to minimize crop damage and facilitate the collection process.

- Q: How do olive nets prevent damage from heavy machinery during harvesting?

- Olive nets prevent damage from heavy machinery during harvesting by creating a protective barrier between the machinery and the ground. The nets are spread out beneath the olive trees, catching the falling olives and preventing them from hitting the ground directly. This helps to reduce impact and potential damage caused by the machinery's weight or movement, ensuring a safer and more efficient harvesting process.

- Q: What are the common plastics?

- Polyethylene terephthalate two (PET): common in mineral water bottles, carbonated beverage bottles. PET heat-resistant to 70 degrees, only suitable for warm drinks or frozen drinks, high temperature liquid or heating, it is easy to deformation, it should not be placed in the car for a long time, preferably at room temperature, a one-time use.

- Q: Can olive nets be used in regions with high salinity levels in the soil?

- Olive nets can be used in regions with high salinity levels in the soil, as they primarily serve as a protective barrier to catch and collect the falling olives during harvest. However, it is important to note that high salinity levels in the soil can negatively impact the overall health and productivity of olive trees. Therefore, it is recommended to address and mitigate the salinity issue through appropriate soil management practices before relying solely on olive nets.

- Q: Are olive nets safe for wildlife?

- Yes, olive nets are generally safe for wildlife. These nets are designed to protect the olives from birds and other animals, while still allowing them to breathe and move freely. They are made of lightweight materials that do not harm wildlife or pose any significant risks to their well-being.

- Q: Can olive nets be used for olive trees in regions with high pest populations?

- Yes, olive nets can be used for olive trees in regions with high pest populations. Olive nets are designed to act as a physical barrier, preventing pests such as insects and birds from accessing the olive trees and causing damage. This can help protect the olive crop from pest infestation and reduce the risks associated with high pest populations.

Send your message to us

White Food Grade PVC PU Conveyor Belt 1.6mm 1.8mm 2.0mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords