1 2 Inch Aluminum Plate

1 2 Inch Aluminum Plate Related Searches

Aluminum Plate 1 2 Inch Thick 2 Inch Aluminum Plate 1 2 Aluminum Plate 1 2 Thick Aluminum Plate 1 Inch Aluminum Plate 2 Inch Thick Aluminum Plate 2 Mm Aluminum Plate 1 Inch Thick Aluminum Plate 1/2 Inch Aluminum Plate 2mm Aluminum Plate 1 2 Aluminum Diamond Plate 2 Aluminum Plate 2 Thick Aluminum Plate Aluminum Plate 1 Inch Thick Aluminum Plate 2mm 1 4 Inch Aluminum Plate 1/2 Inch Thick Aluminum Plate 1 8 Inch Aluminum Plate 1 2 Aluminum Plate Weight 1 Thick Aluminum Plate 1 Aluminum Plate Aluminum Plate 1/2 Inch Thick 1 4 Inch Thick Aluminum Plate 1 4 Aluminum Plate 1 8 Inch Thick Aluminum Plate Aluminum 1/2 Plate 1/2 Thick Aluminum Plate Aluminum Plate 1/2 Thick 1/2 Aluminum Plate 1/8 Inch Aluminum Plate1 2 Inch Aluminum Plate Supplier & Manufacturer from China

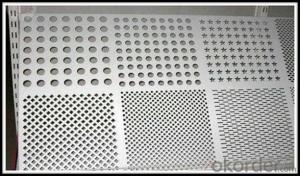

1/2 Inch Aluminum Plate is a versatile product that is widely used in various industries due to its lightweight, corrosion-resistant, and high-strength properties. This type of aluminum plate is available in different grades, such as 6061, 6063, and 7075, each with its own unique characteristics and applications.The 1/2 Inch Aluminum Plate is commonly used in construction, aerospace, automotive, and marine industries, among others. It is ideal for applications requiring high strength-to-weight ratios, such as structural components, aircraft parts, and marine vessels. Its corrosion resistance makes it a popular choice for outdoor applications, while its lightweight nature is beneficial for reducing overall weight in vehicles and aircraft.

Okorder.com is a leading wholesale supplier of 1/2 Inch Aluminum Plate, offering a vast inventory of this product to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the 1/2 Inch Aluminum Plate is sourced from reputable manufacturers and is available at competitive prices.

Hot Products