Endless Green PVC Conveyor Belt with MOQ 1 PCS

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

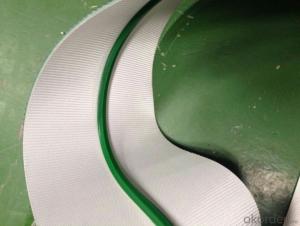

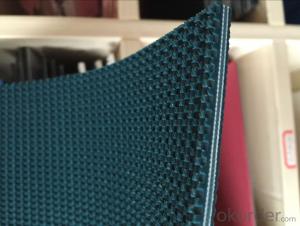

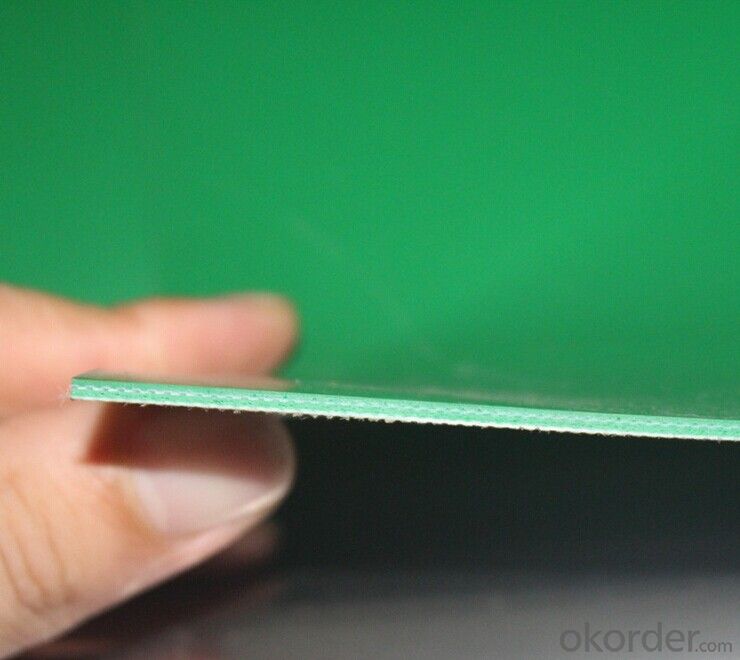

Endless Green PVC Conveyor Belt with MOQ 1 PCS

Conveyor Belt Description:

PVC belts are made of PVC and polyester fabric for industrial light transporting, it is an essential part of the conveyor system.

Whole core Flame retardant conveyer belt is made from the whole belt core via dipping and plastifying in polyvinyl chloride (PVC) dipping agent or sulfuration. It features largely in the high strength, large freight volume and stable conveyance performance. Besides, it is fire retardant, anti-static, shock resistant, wearable and corrosion resistant.

Different widths, patterns, colors, plies, thicknesss, profiles all are available, Conveyor belts of pvc with cold, abrasion resistance, antislip, anti-static features can suit different enviromental conditions.

Conveyor Belt Feature

1)Low stretch;

2)Low maintenance;

3.Anti-static;

4)Flexible;

5.Lightweight;

6)Impervious to moisture,acids,oils,gases,sunlight;

7)Excellent fastener holding;

8)Excellent resistance to tearing,peeling and impact;

9)Endless belt splicing;

10)Special wear resistant edge design;

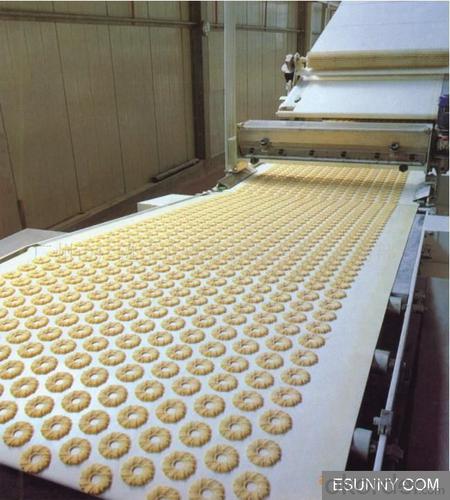

Conveyor Belt Applications

Food industry

Logistic industry

Quartz rock industry

Artificial board industry

Marble industry

Tobacco industry

Printing & dyeing industry

Fitness industry

Conveyor Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products based on your requirements.It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1)All raw material we used are environmental-friendly;

2)Skilful workers care every details in handling the producing and packing processes;

3)Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance payment before shipment.

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What materials do you use for plastic moulds?

- As there are many varieties of plastics, the requirements for plastic products vary greatly, and various materials for making plastic moulds are also put forward

- Q: What is the most effective way to reduce the environmental pollution caused by plastic bags?

- First, strengthen management.Two, prohibit the use of disposable biodegradable plastic packaging.Three, forced recycling.

- Q: Can olive nets be used year-round?

- No, olive nets are typically used only during the olive harvesting season, which is usually in the late autumn or early winter.

- Q: Do olive nets require regular maintenance?

- Yes, olive nets do require regular maintenance. They need to be cleaned and inspected regularly to remove debris, prevent blockages, and ensure their effectiveness in protecting the olives from pests and birds. Additionally, any damages or tears should be repaired promptly to maintain the integrity of the net.

- Q: How do olive nets prevent fruit theft in the orchard?

- Olive nets prevent fruit theft in the orchard by creating a physical barrier between the fruit and potential thieves. These nets are placed over the trees, covering the entire canopy, and secured tightly to prevent any gaps or openings. This prevents unauthorized access to the fruit, making it difficult for thieves to steal the olives without removing the netting first, which is time-consuming and raises the risk of detection.

- Q: Can olive nets be used in areas with high humidity?

- Yes, olive nets can be used in areas with high humidity. The nets are designed to protect the olives from birds and pests, and can withstand various weather conditions, including high humidity. However, it is important to ensure proper ventilation and periodic removal of moisture to prevent any potential damage to the olives.

- Q: What harm does it take to eat hot food with plastic?

- Illegal plastic bags of household waste, the main ingredients of waste plastics are polyvinyl chloride, inferior additives in the processing process and if not conforming to the provisions of the state or seriously exceed the standard combination, will produce a strong carcinogen. With such plastic bags to wrap food, fruits and vegetables, harmful substances will be absorbed on the food, even if it is difficult to remove the rinse.

- Q: Can olive nets be used to protect against theft or vandalism?

- Olive nets are primarily used for agricultural purposes, such as protecting olive trees from birds or collecting olives during harvest. While they may offer some physical barrier, they are not specifically designed or commonly used for protecting against theft or vandalism. Other security measures, such as fences, alarms, or surveillance systems, would be more suitable for such purposes.

- Q: Can olive nets be used in organic certification processes?

- Yes, olive nets can be used in organic certification processes. However, it is essential to ensure that the nets used are made from organic materials and do not contain any synthetic or harmful substances. The use of olive nets in organic farming is primarily for protecting the olives from birds and other pests, which aligns with the principles of organic agriculture.

- Q: What are the advantages and disadvantages of plastics?

- The density of plastic is between 0.8-2.2g/cm3, generally only steel 1/3-1/4, aluminum 1/2, concrete 1/3, similar to wood. It can reduce the construction intensity and reduce the weight of the building.

Send your message to us

Endless Green PVC Conveyor Belt with MOQ 1 PCS

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords