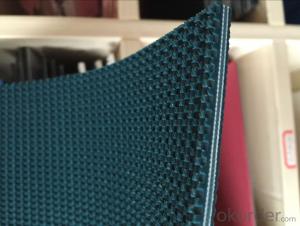

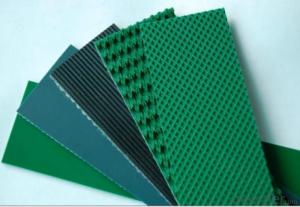

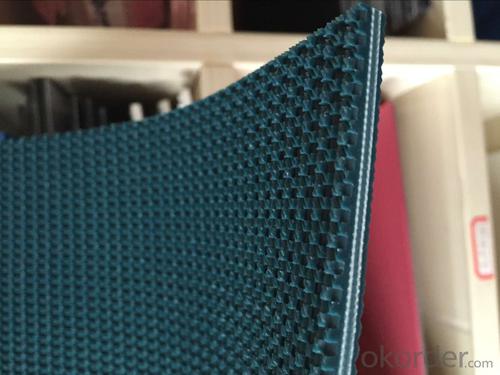

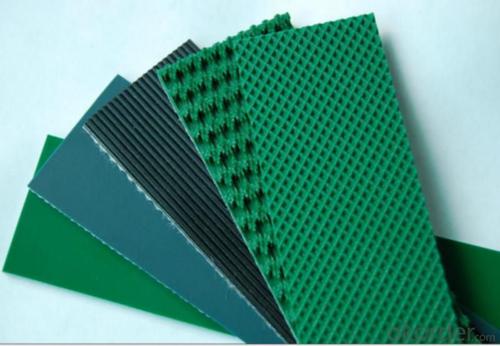

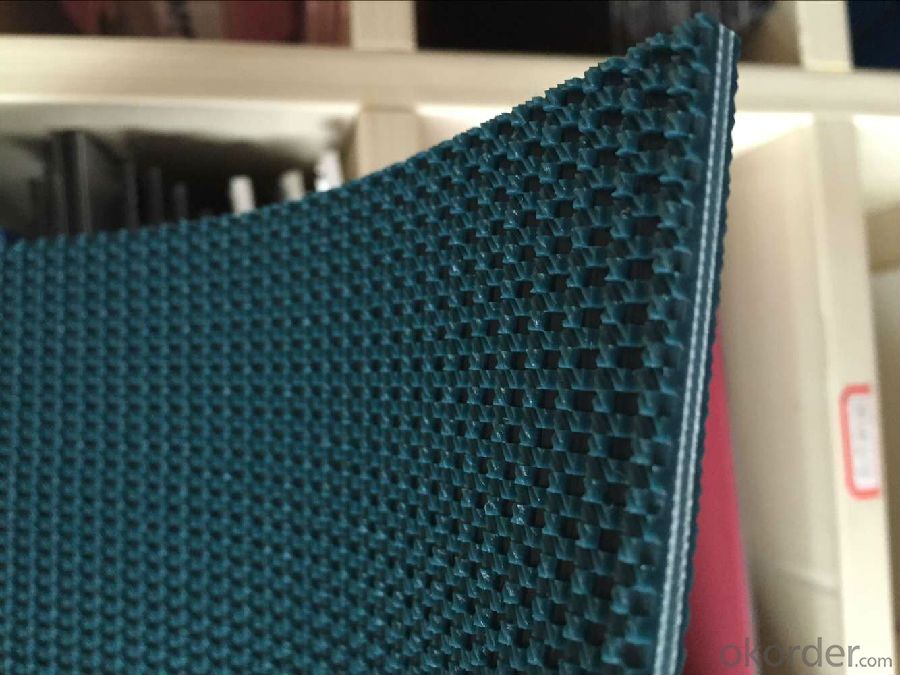

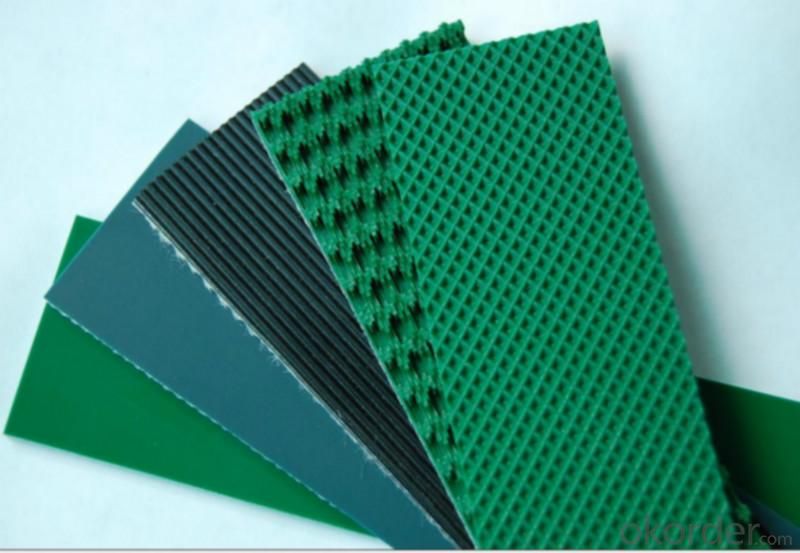

4mm/4.5mm/5mm Green White Rough Top PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

4mm/4.5mm/5mm Green White Rough Top PVC Conveyor Belt

VC / PU Conveyor Belt

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

The main products include flat surface series, anti-slid series which diversified in a lot of textures for meeting different conveying conditions and environment, featuring anti-static, anti-corrosion, flame retardant etc.

There are wide range of patterns of rough top belt available including Diamond, Chevron, Herringbone, Rib, Grid, Wave, Round and Oval nubs, Convex-tooth etc.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Description: 4mm Green PVC conveyor belt.Surface is rough top.Two layers of nature fabric.Two layers of PVC glue.

The maximun wigth: 2000mm

Temperature:-10℃~+80℃

Specification:

1.Belt curves are developed by our company has the domestic advanced technology level of quality .

2.products.Whether driven tensioning tapered roller precision machining, or the fan belt anti-deviation

adjustment

3.techniquesare reflected in the technical and process my company on the lead position.

4.Turning belt can be made into 90 °, 180 ° or even user needs at any angle. The turning radius according to the size and weight of the object conveyor may be designed to 300MM/600MM/900MM/1200MM/1500MM/2000MM/3000MM other specifications.

5.Curve conveyor belt with the straight line, to achieve the perfect

angle transporting goods during transport can maintain its relative position

synchronized conveyor. Particularly for use in the delivery of irregular items,

such as bags, bulk, small parts.

Features:

1)Low stretch;

2)Low maintenance;

3.Anti-static;

4)Flexible;

5.Lightweight;

6)Impervious to moisture,acids,oils,gases,sunlight;

7)Excellent fastener holding;

8)Excellent resistance to tearing,peeling and impact;

9)Endless belt splicing;

10)Special wear resistant edge design;

Product Photos

For more informations,please contact us freely,thank you.

- Q: Are olive nets resistant to high winds?

- Yes, olive nets are designed to be resistant to high winds. They are made from strong and durable materials that can withstand strong gusts of wind without getting damaged or blown away.

- Q: Why should I granulate before injection? What's the advantage of granulation?

- Direct crushing material can also be used, but the direct crushing of the material due to uneven particle size, resulting in uneven storage process, the process becomes more unstable. And granulation, the particles are generally more homogeneous, and later injection molding process is relatively stable! As for the difference between granulation and injection: This is the two process, granulation is a number of waste plastics through melting, extrusion, in the cutting machine to cut into granular. During the granulation process, some additives can be added to improve the performance of waste plastics. Something like a toughening agent. Plastic injection is the formation of plastic products by melting the plastic material and then by pressing it into the mold. Popular to say is: injection molding is the raw material into plastic products, and granulation is to make plastic products again "raw material""!

- Q: How do you clean an olive net?

- To clean an olive net, start by removing any debris or leaves from the netting. Then, rinse it with water to remove dirt and grime. For stubborn stains, you can use a mild detergent and scrub gently with a soft brush or sponge. Finally, rinse the net thoroughly and allow it to air dry before storing it.

- Q: How do you prevent olive nets from causing injuries to workers during harvesting?

- To prevent olive nets from causing injuries to workers during harvesting, several measures can be taken. Firstly, proper training and education should be provided to workers on the safe use of nets and the potential risks involved. This includes demonstrating the correct techniques for handling and setting up the nets. Secondly, it is crucial to ensure that the nets used are of high quality and in good condition. Regular inspections should be conducted to identify any damages or weak spots that may pose a risk. Prompt repairs or replacements should be made as needed. Additionally, it is important to establish clear guidelines and protocols for the use of nets. This includes defining safe working distances from the nets and implementing strict procedures for workers to follow to avoid entanglement or falls. Proper supervision and monitoring during the harvesting process can help identify any unsafe practices or potential hazards. Regular communication and feedback channels should be established to encourage workers to report any concerns or incidents related to the use of olive nets. Overall, a combination of training, proper equipment maintenance, clear guidelines, and effective supervision can significantly reduce the risk of injuries caused by olive nets during harvesting.

- Q: How do you remove olives trapped in the net?

- To remove olives trapped in the net, you can try gently shaking or tapping the net to dislodge them. Alternatively, you can carefully cut the netting around the trapped olives using scissors or a knife. Just be cautious not to damage the olives in the process.

- Q: How do olive nets prevent damage from wind-blown debris?

- Olive nets prevent damage from wind-blown debris by acting as a protective barrier, catching and trapping the debris before it reaches the olives. The nets are designed to be durable and tightly woven, ensuring that even small debris particles cannot pass through. This helps to safeguard the olives and prevent any potential damage or contamination caused by the debris.

- Q: Are there any specific techniques for preventing olive net damage from strong winds?

- Yes, there are specific techniques for preventing olive net damage from strong winds. These techniques include properly securing the nets using heavy weights or anchoring systems, ensuring that the nets are tightly stretched and properly tensioned, using reinforced netting materials that can withstand strong winds, and regularly inspecting and maintaining the nets to identify and repair any weak points or damage. Additionally, planting windbreaks or installing windshields around the olive trees can also help in reducing the impact of strong winds on the nets.

- Q: How does an olive net affect the overall soil fertility in the olive grove?

- An olive net does not directly affect the overall soil fertility in an olive grove. The primary purpose of an olive net is to protect the olives from birds or other animals, preventing damage and ensuring a higher yield. Soil fertility, on the other hand, depends on factors such as nutrient content, organic matter, pH levels, and proper irrigation and fertilization practices. These factors contribute to the overall health and productivity of the olive trees, while the olive net serves as a protective measure for the fruit.

- Q: Can olive nets be used on olive trees grown in windy areas?

- Yes, olive nets can be used on olive trees grown in windy areas. Olive nets provide protection to the trees and help prevent wind damage to the branches and fruits. They act as a barrier, reducing the impact of strong winds and preventing the loss of olives.

- Q: What happens when plastic gets wet and sticky?

- The plastic is made of monomers as raw materials, polymer by polyaddition or polycondensation polymerization, can freely change the composition and form style, composed of synthetic resin and filler, plasticizer, stabilizer, lubricant, pigment and other additives.

Send your message to us

4mm/4.5mm/5mm Green White Rough Top PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords