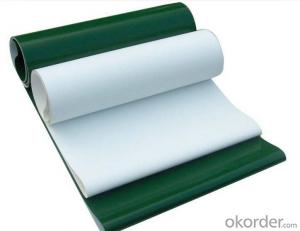

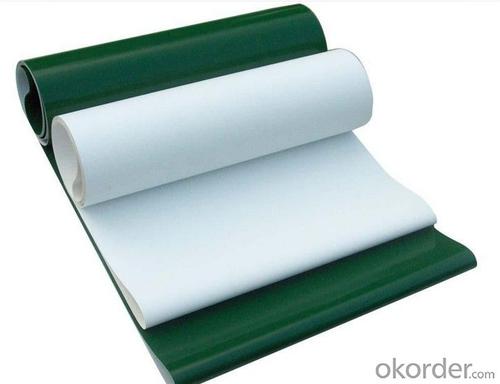

PVC/PU Food Conveyor Belt White Green Color Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC/PU Food Conveyor Belt White Green Color Belt

Description

This light-duty conveyor belt takes braided fabric made of polyester threads that

has undergone special technical treatment as the carrier framework. One or both

sides are coated with rubber, PVC, PU or PE. It features great strength, little

elongation or extension, good bending and twisting ability, stable running, and

long service life.

PU conveyor belt has the common traits of high tensile strength, good bending, lightness,

thinness and toughness. It also has the outstanding traits of anti-germ,

wear-resistance, oil-resistance, nonpoisonous and sanitary, and easy to clean.

All of these conform to the management requirement of conveying non-packed food.

PE conveyor belt has the common traits of high tensile strength, good bending, and

stable running. It is also nonpoisonous and sanitary, easy to clean, and has smooth

surface. It can touch with food directly. It is the ideal matching equipment of deep-processing industry for tobacco, food, meat and fishery, fruit and vegetable.

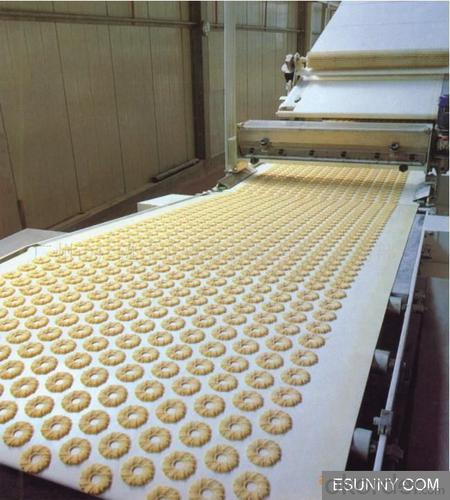

Applications

Widely used in food industry. Transport the material in bulk, canning and packed In box. The material includes grain, cooky, candy, vegetables, fruit, fowl, meat and so on.

Also widely used in soft material industry. Used in those field, including tobacco, electron, textile, printing and dyeing, machine manufacturing, print and package, paper processing, pottery, marble, wood processing,car shell molding, cable fishing wire, aluminium parts processing and etc.

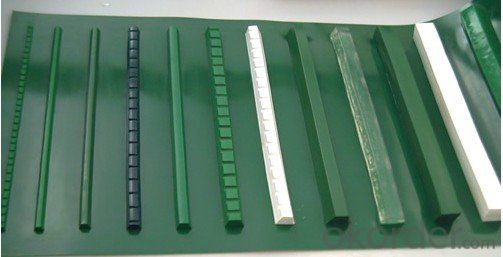

Product pictures:

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: How do you determine the optimal time to install olive nets for harvesting?

- The optimal time to install olive nets for harvesting can be determined by considering the ripeness of the olives. This can be assessed by observing the color change of the olives from green to black or purple, as well as their firmness. Additionally, monitoring the sugar content and taste can also help determine when the olives are at their best for harvesting. Consulting with local agricultural experts or experienced olive growers in the specific region can provide valuable insights and recommendations on the ideal timing for installing the nets to ensure a successful harvest.

- Q: How does an olive net affect the quality of the olive oil produced?

- An olive net can positively affect the quality of the olive oil produced by preventing the olives from falling onto the ground and getting dirty or damaged. The net helps in collecting the olives directly from the tree, reducing the risk of contamination and preserving their freshness. This ultimately leads to a higher quality olive oil with enhanced flavor and aroma, as well as a longer shelf life.

- Q: Can olive nets be used for other types of nuts?

- No, olive nets are specifically designed for harvesting olives and may not be suitable for other types of nuts due to variations in size, weight, and harvesting methods.

- Q: Can olive nets be used to protect against frost damage?

- Yes, olive nets can be used to protect against frost damage. These nets are commonly used in olive groves to shield the trees from frost during cold weather conditions. The nets act as a barrier, preventing direct contact between the frost and the olive trees, thus reducing the risk of frost damage.

- Q: How many kinds of plastic materials are there?

- The molecular structure of thermosetting plastics is the body structure, softening also occurs in heated, can plastic into a certain shape, but is heated to a certain extent or amount of curing agent, hardened stereotypes, re heating will not soften and change the shape of the. Thermosetting plastic processing, molding, the heat is no longer softening, and therefore can not be recycled, such as phenolic plastics, amino plastics, epoxy resin, etc. belong to this kind of plastic. Thermosetting plastic forming process is more complex, so continuous production has some difficulties, but its good heat resistance, not easy to deformation, and the price is relatively low.

- Q: Can a plastic water cup be boiled in general?

- 7 cup of low plastic cup is made of polycarbonate, PC, used to call a bisphenol A material in the production process of PC material, PC material will be more or less in the presence of bisphenol A monomer, the higher the temperature, the faster speed of release.

- Q: Are olive nets resistant to extreme temperatures?

- Yes, olive nets are generally resistant to extreme temperatures. They are designed to withstand both high heat and cold conditions, making them suitable for use in various climates.

- Q: Are there any specific safety precautions to consider when using olive nets?

- Yes, there are several safety precautions to consider when using olive nets. Firstly, it is important to wear appropriate protective gear such as gloves and eye protection to avoid any potential injuries. Additionally, ensure that the nets are securely fastened and properly maintained to prevent accidents. Be cautious while setting up or dismantling the nets to avoid tripping or falling. Lastly, be mindful of the weight and size of the olives collected in the nets to prevent strain or injury while handling or transporting them.

- Q: How do olive nets prevent olives from being damaged by diseases?

- Olive nets prevent olives from being damaged by diseases by acting as a physical barrier, preventing pests and pathogens from coming into direct contact with the fruit.

- Q: How do olive nets prevent olives from being damaged by hailstorms?

- Olive nets act as a protective barrier over the olive trees, preventing hailstones from directly hitting the olives. The nets absorb the impact of the hailstones, reducing the force with which they hit the olives, thus minimizing potential damage.

Send your message to us

PVC/PU Food Conveyor Belt White Green Color Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords