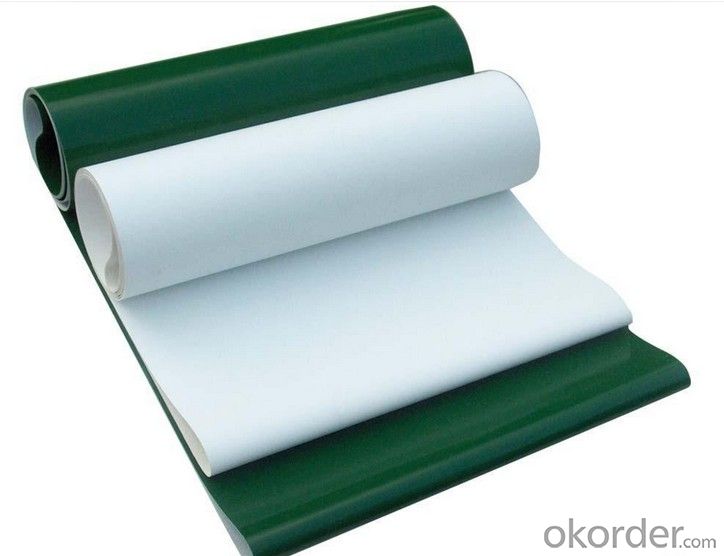

Light Duty Green White PVC Conveyor Belt In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Duty Green White PVC Conveyor Belt In Food Industry

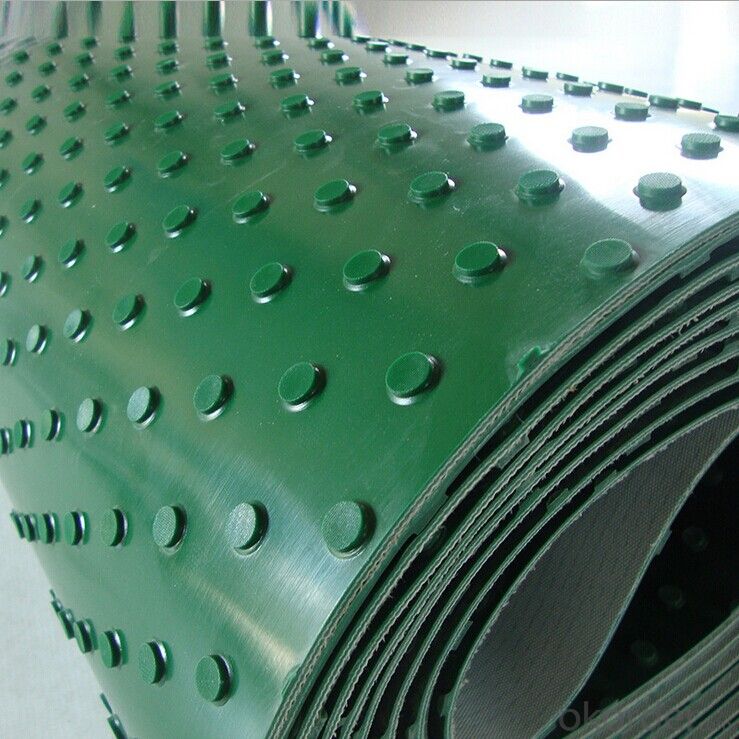

Descriptions of PVC Conveyor Belt

With advanced coating machine and other excellent facilities, we are professionally producing PVC&PU light conveyor belts, which are extremely suitable for light industry such as beer industry, paper making industry, food industry, textile industry etc.

Thickness: 2.0mm

Width: Width of the largest production 3 meter

Length: According to the customer request production. Regular length is 100 meters.

Color: White, green, black etc.

Can be produced as customers' requirements, such as thickness, width and length.

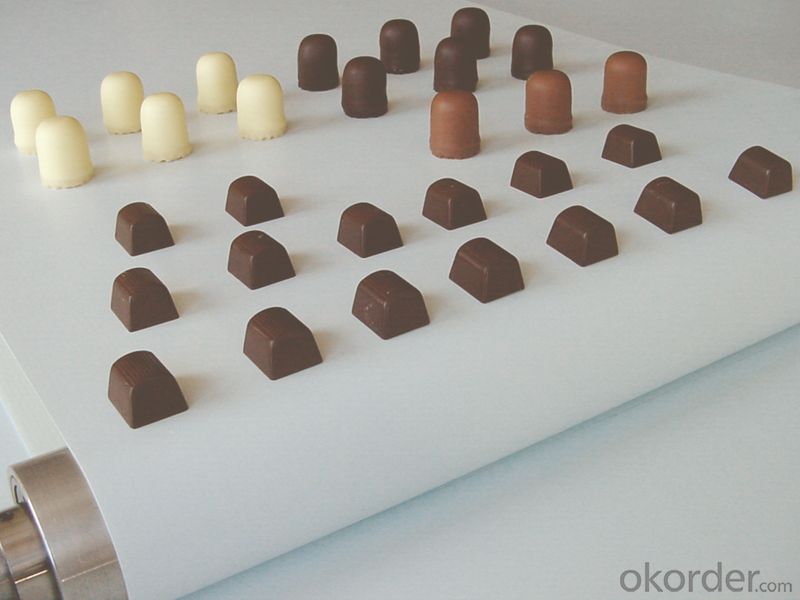

Features of PVC Conveyor Belt

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise (LdB belts)

* Working temperature ranges from -10 to 80Deg.C

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q: Is work in rubber products harmful to health?

- The raw material of rubber products is rubber compound, and the rubber compound has five components:Main rubber. Rubber main glue is not toxic.Reinforcing agent. Most of the reinforcing agents are not toxic.Softener. Is the most emollient mineral oils, high temperature volatile hazardous substances.Antioxidant. Some poisonous.Vulcanizing agent. The vulcanizing agent is generally sulfur, sulfur will release a high temperature sulfur dioxide, sulfur dioxide, sulfur dioxide, hydrogen sulfide gas three.

- Q: What are the uses of ethylene propylene rubber?

- The ethylene propylene rubber has excellent water resistance, heat resistance and weather resistance, and convenient construction etc. Therefore, ethylene propylene rubber in the construction industry is mainly used for plastic playground, waterproof materials, housing seal doors and windows, glass curtain wall sealing, sanitary equipment and pipeline seal etc.. Ethylene propylene rubber in the construction industry, the largest amount of plastic sports field and waterproofing membrane, in terms of domestic consumption, has accounted for ethylene propylene rubber total amount of 26%-28%. A waterproof roll made of EPDM that has gradually replaced other materials (such as CMS), especially waterproof rolls used in underground structures.

- Q: Rubber and metal have to be sealed before they are too strong

- Different materials and O-ring O-ring compression the change of general material such as NBR, NR, nitrile rubber, natural rubber, chloroprene rubber CR, EPDM three EPDM, HNBR hydrogenated nitrile rubber, silica gel SILICOME SBR Buna, styrene butadiene rubber, SBR, acrylate rubber ACM, compression O-ring or the 20% to calculate. If it is a special material FKM, VITON, PU, FLS silicon fluorine rubber, fluorine rubber, polyurethane, compression of these materials is calculated by 15% o ring.

- Q: Why is rubber resistant to compression and wear better than metal?

- Rubber belongs to high polymer material, so it is decided that he can win in earthquake resistant, high-density and high elasticity working environment

- Q: What is the specific gravity of natural rubber?

- Natural rubber is composed of rubber, hydrocarbon, water, resin, protein, sugar and inorganic salts, and its specific gravity is 0.90~0.93. The natural rubber without impurities is transparent and yellowish, with good viscosity and dielectric properties, and its tensile properties are generally higher than those of synthetic rubber. Soluble in benzene, solvent naphtha, carbon disulfide, carbon tetrachloride, chloroform, turpentine, etc., but not soluble in ethanol and acetone. With halogen, oxygen, ozone, peroxide, sulfur and so on. Widely used in the manufacture of rubber products, such as tires, rubber shoes, hose, tape, wire and cable insulation materials.

- Q: Properties and specific uses of various rubbers

- 1, natural rubber: mainly used for tires, hoses, tape and other rubber products.2, synthetic rubber: divided into general and special synthetic rubber, synthetic rubber, synthetic rubber such as polybutadiene rubber, styrene butadiene rubber mainly used in the production of tires, rubber shoes, rubber products.

- Q: What's wrong with rubber whitening?

- Rubber whitening (spray cream) the main reason for analysis, rubber spray cream, including rubber surface spray and surface spray cream. Spray (Bloom) is a phenomenon in which liquid or solid agents migrate from rubber to rubber surfaces [1]. It can be seen that the inner compound of rubber will precipitate and form a spray. There are three kinds of forms of rubber spray. Powder spraying, wax injection, injection (also known as exudation).1. powder is a curing agent, accelerator, activator, antioxidant and filler powder with precipitation agent on the rubber surface, and form a layer of powder.2. spray wax is paraffin wax, ceresin wax precipitation etc. on the rubber surface, forming a layer of wax.3. fuel injection is softening agent, tackifier, lubricants, plasticizers and other additives in liquid precipitation of the rubber surface, and form a layer of oil.In practice, frost forms on rubber surfaces sometimes appear in one form, sometimes in two or three forms.

- Q: Why does rubber stink?

- Because of the original gum problem, such as PU or polyurethane will have a foul smell.Highly elastic polymer material with reversible deformation of rubber. It is elastic at room temperature and can produce great deformation under very little external force. It can be restored to original state after removing external force. Rubber is completely amorphous polymer, its glass transition temperature (T, g) is low, the molecular weight is often large, more than hundreds of thousands.

- Q: What are the causes of the rubber products breach?

- First: the use of rubber joints in the process of linking the length is not enough to force beyond the length of the link, the expansion of the scope of contraction may also splitSecond: rubber joints, the strength of the link is relatively low, then if the adhesive method is not accurate, the strength of the joint will be lower, there may be crackingThird: rubber joints after installation, in other places free here beyond the extension range of pipe strap, there may be cracking.Fourth: rubber joints in the outdoor adverse weather, explosion, sun, etc., lower than the use of temperature may also crack.Fifth: in the process of production of vulcanized rubber joint used in rubber function is not good or has been since sulfur failure, excessive grinding, wire rope and other parts of the rust, the joint strength will be greatly reduced, when in use, will likely easily disconnect joint phenomenon

- Q: Which kind of rubber has the best wear resistance?

- Three yuan ethylene propylene rubber introducedThree yuan ethylene propylene rubber is ethylene, propylene and non conjugated diene three yuan copolymer, began commercial production in 1963. The consumption of the whole world is 800 thousand tons every year. The most important feature of EPDM is its superior oxidation resistance, ozone resistance and corrosion resistance. Because three yuan ethylene propylene rubber belongs to polyolefin family, it has excellent curing property. Of all rubbers, EPDM has the lowest specific gravity. It absorbs large amounts of fillers and oils and has little effect on properties. Therefore, rubber compounds with low cost can be made.Viton (fluorocarbon rubber) is a synthetic rubber containing fluorine, fluorocarbon rubber high temperature resistance, oil resistance and various chemical erosion characteristics, is the science and technology of modern aviation, missiles, rockets, space navigation and so on the tip of indispensable material. In recent years, along with the automobile industry on the reliability and safety requirements continue to improve, the amount of fluorocarbon rubber in cars is also growing rapidly.

Send your message to us

Light Duty Green White PVC Conveyor Belt In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords