PVC Light Weight Conveyor Belt for Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Light Weight Conveyor Belt for Food Industry

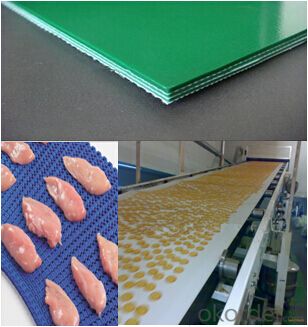

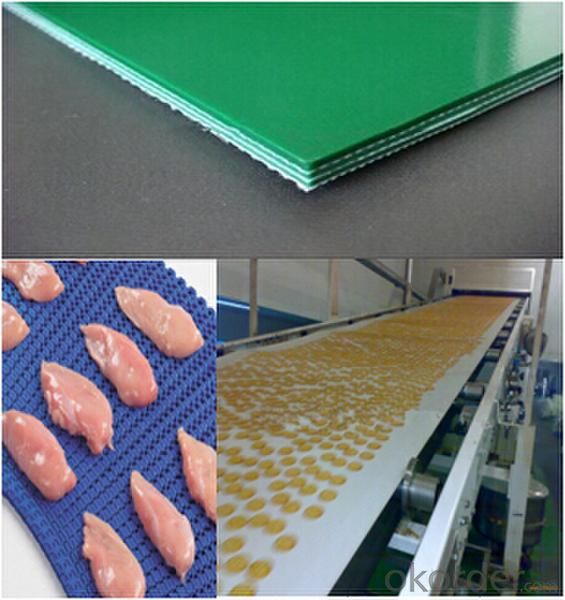

Description of PVC Food Conveyor Belt:

Food conveyor belt choose high quality high strength polyester fabric as the core, good flexibity, using environmental PU and PVC as the material of conveyor belt, one of them, the PU belt not only have common character of conveyor belt hight tensile stength, light, thin, but also oil-resistant, abrasion-resistant, non-toxic.The above could meet the food grade standards,and could contact with food,no peculiar smell.

Characteristics of PVC Food Conveyor Belt

It adopt high-intensity polyester filament and yarn weave as the whole core, and then is impregnated by the PVC. Suitable for applications in dry conditions at a slope angle of no greater than 16 degrees.

Cover thickness can be from 0.5 to 4 mm.

Features of PVC Food Conveyor Belt

Non-conductive

Anti-static

FDA and HACCP standards

Resistant to fats, chemicals, oil fat and abrasion

Dimensional stability

Less noise

Various surfaces with high, medium, and low coefficient friction

Special belts can also be manufactured complete with

1) Guides, profiles and sidewalls fitted by means of high frequency or hot air welding machines.

2)Curved or Corner conveyor belts it allows the solving of logistic problems through the deviation of the conveying system from a few degrees to a 180°C turn.

3)Belts can be made endless, spliced or with prepared ends for on-site splicing to be done with dedicated Adhesives.

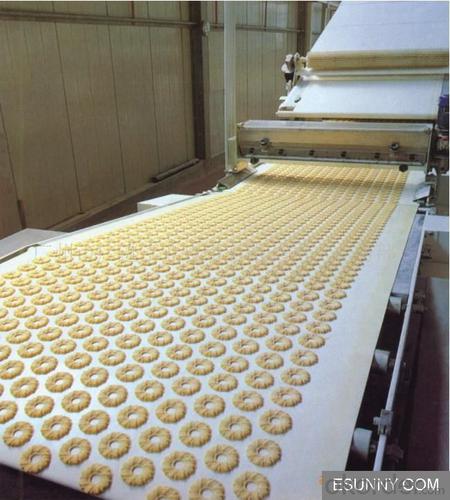

Photo of PVC Conveyor Belt:

If you want to find more details about the pvc food conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What is the cause of the bursting of rubber products and how should they be improved?

- Improvement measures: 1.. Adjust the molding sulfuration temperature, adjust the temperature of the upper and lower plate. 2. adjust the exhaust distance and exhaust time. 3. in strict accordance with the mixing process standards or adjust the formula and mixing process, avoid the use of time is too long to place material (fast cooked). 4., in the explosive edge position plus running trough. 5. control the weight of a single adhesive.

- Q: What does the rubber tire do to people?

- Rubber is divided into natural rubber and synthetic rubber according to its raw material. According to the form is divided into block rubber, latex, liquid rubber and rubber powder. Latex as a rubber colloidal water dispersion; liquid rubber as an oligomer of rubber, not before the vulcanization is generally viscous liquid; powder rubber is the latex processing into powder, in order to benefit ingredients and processing. Thermoplastic rubber, developed in 1960s, does not require chemical vulcanization and is shaped by thermoplastic processing. Rubber according to the use of divided into general and special type of two categories. It is not easy to insulator, conductive, but if water or different temperature, are likely to become a conductor. Conduction is the conduction of electrons in a substance, molecule, or ion.

- Q: What kinds of rubber are edible grade safety rubber?

- According to the requirements of tolerance solution, select the appropriate rubber material (general rubber -- basic environmental protection without pollution, mainly small rubber) material, plasticizer, filler to use food grade raw materials such as calcium carbonate, not to use food grade industrial grade;

- Q: Excuse me, what is in the rubber rubber, glue them, what is the difference?

- The toughness greatly improved than rubber glue. If the car tire is cooked. Generally the same thickness, soft as glue.

- Q: Properties and specific uses of various rubbers

- Synthetic rubber is made by synthetic methods, and different kinds of rubber can be synthesized with different raw materials (monomers). Such as, butadiene rubber, chloroprene rubber, styrene butadiene rubber and so on. The yield of synthetic rubber has greatly exceeded that of natural rubber, of which the largest yield is styrene butadiene rubber.

- Q: What is the difference between natural and synthetic rubber?

- Natural rubber is one of synthetic rubber, and synthetic rubber can be divided into many kinds.

- Q: Half finished rubber film surface white is going on

- Because inside the rubber compounding agent reachsupersaturation, rubber compounding agent near surface precipitates first, then from the inner to the surface migration of precipitation when complexing agent in the rubber to reduce its saturated state, precipitation process ended. Causes the complexing agent to achieve the supersaturation state, causes the rubber spraying frost the main reason to have: the rubber formula design is improper, the craft operation is not proper, the raw material quality fluctuates, the storage condition is poor, the product owes sulfur, the product aging and so on.

- Q: Is it necessary to use rubber products for steel structure buildings?

- There must be a rubber cushion for the gear of the crane beam, and there is also a rubber cushion between the crane track and the crane beam. Of course, not all deformation joints are rubber, depending on how to choose the design node.

- Q: How can rubber be made into rubber when it is made?

- Just cut off the rubber is not available, belongs to the first rubber, according to the products and the use of working conditions to set the formula, made of mixed rubber, vulcanized on the vulcanization machine with mold has been good, curing after trimming, testing, packaging. The required rubber products will be ready.The process flow of the production process is:Raw material preparation, plasticization, blending, molding, vulcanizing, cleaning and testing

- Q: What's the difference between natural rubber and three yuan ethylene propylene rubber?

- The dielectric properties of natural rubber are a nonpolar substance that is soluble in non-polar solvents and non-polar oils. Natural rubber is not resistant to cyclohexane, gasoline, benzene and other media, non vulcanized rubber can be dissolved in the above medium, vulcanized rubber swelling. Natural rubber insoluble in polar acetone, ethanol, more insoluble in water, resistant to 10% hydrofluoric acid, 20% hydrochloric acid, 30% sulfuric acid, 50% sodium hydroxide and so on.

Send your message to us

PVC Light Weight Conveyor Belt for Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords