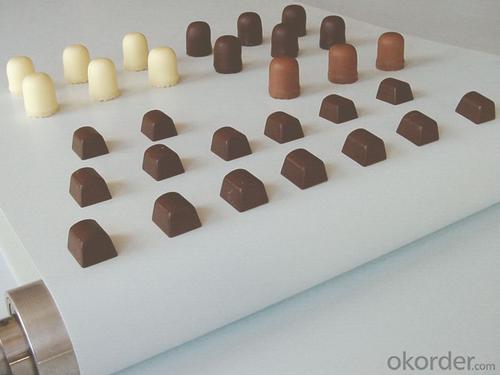

Light Duty PVC/PU Conveyor Belt for Food Processing Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Duty PVC/PU Conveyor Belt for Food Processing Industry

PVC conveyor belts are made of PVC which is commonly abbreviated PVC and polyester fabric, it's working temperate range is from -10 to 80 degrees, with good lateral stability, now it is widely use in light industry, such as airports, postal automation, parcel handling, treadmills, packagin and wrapping, confectionery industry, food processing industry, paper printing industry and so on..

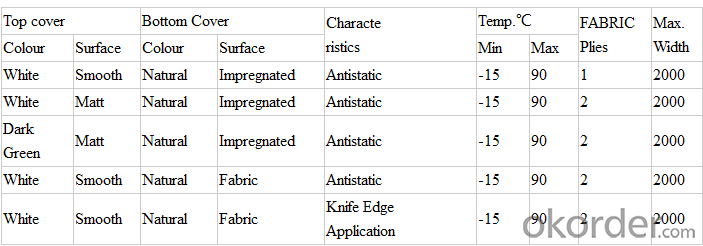

PVC/PU conveyor belt

1. material: PVC/PU

2. color: white,dark green,sky bule or as request

3. surface: smooth,matt

Specification:

1.Belt curves are developed by our company has the domestic advanced technology level of quality .

2.products.Whether driven tensioning tapered roller precision machining, or the fan belt anti-deviation

adjustment

3.techniquesare reflected in the technical and process my company on the lead position.

4.Turning belt can be made into 90 °, 180 ° or even user needs at any angle. The turning radius according to the size and weight of the object conveyor may be designed to 300MM/600MM/900MM/1200MM/1500MM/2000MM/3000MM other specifications.

5.Curve conveyor belt with the straight line, to achieve the perfect

angle transporting goods during transport can maintain its relative position

synchronized conveyor. Particularly for use in the delivery of irregular items,

such as bags, bulk, small parts.

Working environment:

1. the working environment, conditions and conditions

2.Need to consider the time of day every day operation, the operating frequency, the service life of the belt conveyor, feeding and unloading methods.

3.Work environment, conditions: ambient temperature, outdoor or indoor, environmental requirements, mobile or fixed, telescopic requirements.

Product Photos

For more informations,please contact us freely,thank you.

- Q: Can olive nets be used to promote organic certification?

- Yes, olive nets can be used to promote organic certification. Olive nets are commonly used in organic farming practices to protect olive trees from pests and to collect fallen olives without causing damage. The use of these nets demonstrates a commitment to sustainable and environmentally friendly farming methods, which aligns with the principles of organic certification.

- Q: Can olive nets be used in combination with other types of insect control methods?

- Yes, olive nets can be used in combination with other types of insect control methods. Olive nets are primarily used to protect olive trees from insects, but they can be complemented with additional measures such as insecticides, pheromone traps, or biological controls to enhance the effectiveness of pest management.

- Q: Can olive nets be used for olive trees in high-altitude areas?

- Yes, olive nets can be used for olive trees in high-altitude areas. Olive nets are designed to protect the olives from birds and other pests, regardless of the altitude.

- Q: Can olive nets be used for olive tree light exposure control?

- Yes, olive nets can be used for olive tree light exposure control. These nets are specifically designed to regulate the amount of sunlight that reaches the olive trees, allowing for better control over their growth and fruit development.

- Q: Can olive nets be used on trees with a wide canopy?

- Yes, olive nets can be used on trees with a wide canopy. Olive nets are designed to protect the olive fruits from birds and other pests. They are available in various sizes and can be easily spread over the tree canopy to prevent birds from reaching the olives. Their flexible and adjustable nature allows them to be used on trees with a wide canopy as well.

- Q: Do olive nets affect the yield of the olive trees?

- Yes, olive nets can significantly affect the yield of olive trees. These nets are commonly used to protect the olives from birds and other pests, reducing damage and loss of the crop. By preventing the olives from being eaten or knocked off the trees, olive nets help maintain a higher yield and ensure a better harvest.

- Q: Can olive nets be used on trees with a small trunk?

- Yes, olive nets can be used on trees with a small trunk. Olive nets are designed to protect olive crops from birds and other animals. They can be easily adjusted and secured around trees of various sizes, including those with small trunks, providing effective coverage and protection.

- Q: What if the plastic is broken?

- Hot melt bonding (plastic welding), hot melt, also known as plastic welding, is the basic method of thermoplastic connections. Plastic welding is the process of heating plastic products at the bonding place, melting them, and then connecting the two products into a whole after cooling.

- Q: How do olive nets prevent damage from wild animals?

- Olive nets prevent damage from wild animals by creating a physical barrier that prevents them from accessing the olive trees and fruits. The nets are usually installed around the trees, enclosing the entire area, effectively deterring animals such as birds, rodents, and larger mammals from reaching the olives. This prevents them from feeding on the fruits or causing any potential damage, ensuring a successful harvest.

- Q: Can olive nets be used for other types of crops?

- No, olive nets are specifically designed and used for protecting olive trees and harvesting olives. They may not be suitable for other types of crops due to variations in plant size, shape, and harvesting methods.

Send your message to us

Light Duty PVC/PU Conveyor Belt for Food Processing Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords