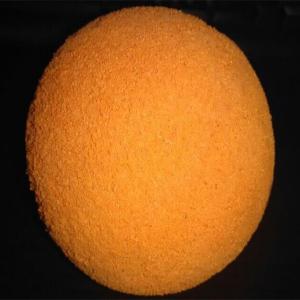

concrete pipeline sponge rubber ball for pipe cleaning

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

concrete pipeline sponge rubber ball for pipe cleaning

SIZE

Cleaning Ball --- DN80, DN100, DN125, DN150

Cleaning Column --- DN125, DN150

STYLE

Cleaning Ball --- hard type, soft type

Cleaning Column --- hard type

FUNCTION

Its main function is used for cleaning concrete pipeline.

PACKING

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Feature

1. It is mainly used for cleaning all kinds of diameter of pump pipe cleaning tool,

maintenance of pipeline cleaning, made channel is more unblocked, unimpeded.

2. Greatly improving the work efficiency.

3. Prolong the service life of the various diameter pipe .

The main products

1. Concrete pump pipe :ST52 concrete pump pipe , 45Mn2 Wear resistant pipes, Twin wall pipes ,Reducer , tee, .ect.

2. the towed concrete pump, Concrete placing boom series.

3. Concrete pump truck fittings : Wear plate and wearring, Svalves, Concrete pump piston , delivery cylinder,.ect

4. Concrete pump clamp : DN80, DN100,DN125,DN150 Casting pipe clamp and Forged clamp.

5. Other accessories: Rubber hose , Cleaning ball , Sponge plug, Seal, The bearing seat, Flange etc.

- Q: What solvent is used to clear the melted rubber layer?

- The acetone extractives are some fatty acids and steroids, some natural antioxidants and accelerators, and can help with the powdery agent in the process of mixing and dispersion of rubber softening effect.Ash containing mainly magnesium phosphate and calcium phosphate salts, copper, manganese, iron and other metal compounds is very small, because these valence metal ion can promote the aging of rubber, so their content should be controlled.

- Q: Rubber Mooney value is what meaning, what is the role of

- Mooney viscosity (Mooney viscosity) also called rotation (Mooney) is determined by numerical viscosity, Mooney viscometer, synthetic rubber can basically reflect the degree of polymerization and molecular weight. The rotor is a standard Mooney viscometer, at a constant speed (2 RPM), rotating in a closed chamber in the sample the viscosity change of shear resistance. The size of the sample and the rotation of the rotor during the curing process, through the force measuring device is displayed on the dial to Mooney units, at the same time interval can be read Mooney, vulcanization curve, door number rose after the first drop, 5 unit increase in the time from the lowest point called the Mooney scorch time, the Mooney scorch and then increased to 30 units and the time that scorch time.

- Q: In addition to the smell of rubber?

- Activated carbon adsorption method of activated carbon is internationally recognized drug experts, activated carbon masks, gas masks are activated carbon. This product uses the physical function of activated carbon, deodorization, detoxification, without any chemical additives, no impact on the human body. Each house from two to three dishes, 72 hours can basically eliminate indoor odor. This method can also be used in combination with other chemical methods, and comprehensive treatment is better.

- Q: How can rubber and mould not be bonded when producing rubber products?

- Mold release can not be solved, we can only start with the mold structure. Because the main reason for adhesion is the complex structure of the product, resulting in strong vacuum adsorption between the mold and the mold. In view of this, we can do a few more exhaust at the appropriate location of the mold. If allowed, you can also modify the product structure, of course, this is unlikely. But really can not do it, this is the best solution.

- Q: What kind of materials should be used for rubber products to keep the brightness of the mirror for a long time?

- To make high gloss products, first of all, there must be good raw materials, followed by a good stain, high light color powder, to achieve free spraying, high light injection molding, first of all need to use high gloss plastic material.

- Q: Does it work in a rubber factory that causes skin irritations?

- Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: How to improve the hardness of rubber?

- Increasing the degree of crosslinking (increasing the dosage of vulcanizing agent and prolonging the curing time properly);Increase the dosage of reinforcing agent, or choose reinforcing agent with high structure and large specific surface area;Hardening resin, high styrene and other hardening agent;

- Q: The difference between plastic rubbers and rubber boots.

- Here's a simple way to do it. Plastics are generally thermoplastic, and rubber is usually thermosetting. You can find a shoe and burn it. See if it's dripping when it's burning, and see if it's soft. If it fits, it's plastic.

- Q: I do rubber products, I would like to ask what metal accessories are rubber products, the specific name is what, good, then points

- High pressure rubber tube, natural rubber tube, Shandong rubber tube, high pressure rubber tube, low pressure rubber tube, Ding Qing rubber tube, high quality rubber tube;

- Q: How to solve the spray of rubber products?

- 1, dry finished products should be packaged sealed, placed in a cool and dry place inventory, avoid sunlightDirect irradiation,2. For the rubber products with the condition of spitting and spitting, the air and temperature at the storage place shall be controlled after the processingDegree and humidity conditions,3, as soon as possible out of storage, not long storage, reduce the aging opportunities of rubber products.

Send your message to us

concrete pipeline sponge rubber ball for pipe cleaning

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords