CNC Ball Grinder KP7060 with Syntec system

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

The lathe is controlled by CNC system; the CNC function of complete machine is realized by all-digital alternating current servo driver's controlingover two servo motors.The horizontal traverse X axis and longitudinaltraverse Z axis of platen are driven by servo motors. They have non-intermittent motion through direct-connection ball screw of fine coupling, to make the whole grinding process realize automatic processing according to program. In this way one person can manage multiple machine: labor costs can be reduced for users and productivity can be enhanced

Grinding ball materials: A105、2Cr13、304、304L、316、316L、LF2、F51、17-4PH、Monel、 ENP、Chrome platino、Tunosten Carbide、Stelite、Inconel and ceramic ball valves etc

System option:Syntec

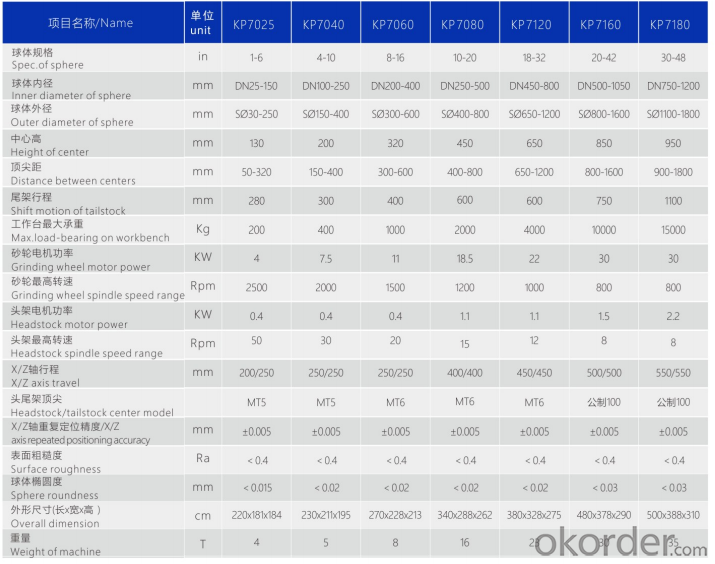

Technical Parameter

Package

Application Area

Suitable for precision machining of large workpieces such as aerospace, automobiles, textile , molds, packaging machinery, mining equipment, etc. It can automatically complete complex machining processes such as boring, drilling, milling, tapping, etc.

Global Sales Market

Cooperative Clients

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-60 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q:Machining center with twist drill bit cast iron speed how much feed how appropriate

- To drill diameter of 10 mm, for example, the speed can take 30 / 0.005 (radius) / 3.14 = 1900 rpm, the actual can take 1500 rpm more appropriate, the amount of feed can be based on empirical formula, select (0.01-0.02)

- Q:Beijing precision machining center CNC machining center features what role

- This CNC system is also based on the instructions of the program to the servo device and other functional components issued by the operation, or to the end of the information to control the various movement of the machine, when the parts of the processing program is over,

- Q:What are the common processing centers in China?

- Processing center is equipped with a knife library, with automatic tool change function, the workpiece after a single folder for multi-process processing CNC machine tools.

- Q:Machining center M19

- G76 is a boring fixed cycle command as long as the fine boring knife when the positioning of some of the machine panel has a spindle positioning key is not in the MDI mode input M19 manual positioning spindle and then hit the HANDLE (hand wheel) mode

- Q:What does metal processing machinery include?

- Automation equipment: automatic tools, bearings, cleaning machines, mechanical drive systems, automatic control systems, packaging equipment, etc .; casting equipment: stamping equipment, lathes, milling machines, forming machines, finishing machines, drilling machines, special purpose machinery

- Q:Machining center in the G98, G99 What does it mean?

- You can come to our school to participate in the training center training, we can tailor your course, to ensure that you learn to learn, through research, access to higher employment opportunities and pay!

- Q:Processing center G99 how to use, it is best to use examples, but also what the R value of what it means.

- Point (R1) drill down drill all the holes in turn. After drilling the first hole with G99, the spindle is quickly raised to point R and moved to the next point after the coordinates of the feed under the drill .R point that is the machine in the Z direction

- Q:What is the M code of the Mitsubishi Machining Center?

- Previously in the school to learn milling machine teachers have not said, M100 is the table rotation B is the rotation angle. M13 is the spindle forward and cutting fluid open

- Q:Engraving and milling machine, processing center (computer gong) and the difference between the carving machine

- China's carved machine industry in 2007 has more than 10,000 units / year, the output value of more than 1.5 billion RMB.

- Q:The difference between milling and reverse milling in cnc CNC machining center

- eave the gap on the left; as the screw continues to rotate, the gap back to the right, in this The moment the table to stop the movement; when the horizontal milling force is large to a certain extent, there will be to promote the table and the screw again to the right of the movement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CNC Ball Grinder KP7060 with Syntec system

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches