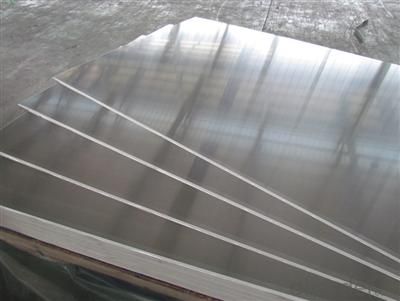

2A12 5052 5083 6061 6083 7075 Aluminum Sheet Price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum sheet specifications:

1) Alloy : 1A99,2A12,2024,2219,2618,2A50,2A70,5A06,5083,6082,7075,7050, 7A85,7020 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 350mm

4) Width:20mm to 3300mm

5)Length: Accord to customer's requirements.

Reliable Quality,Reasonable Price and Good Service.

Any email will be replied with 24 hours. Thanks for your time!

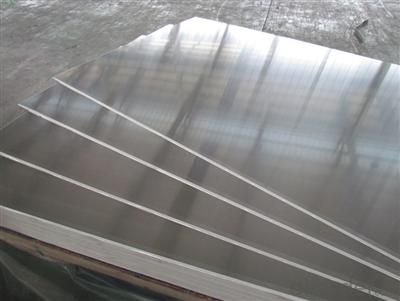

6061 Aluminum plate/ aluminum thin sheet/ aluminum coil/ aluminum pipe application

The main alloy elements of 6061 alloy are Mg and Si and they form into Mg2Si. If it contains a certain amount of Mn and Cr, the bad effect of the iron can be neutralized. Sometimes you could also add a small amount of Cu and Zn to improve the strength of the alloy without decreasing its corrosion resistance obviously. Conductive material also contains a small amount of Cu which helps to counteract the bad effect of Ti and Fe on the electrical conductivity. In order to improve its cutting property, you could also add Pb and Bi. The alloy will has artificial aging hardening function when Mg2Si Solid soluble in aluminum.

6061-T651 is the main alloy elements of 6061 alloy. It is high quality aluminum products which are produced by heat treatment of pretensioning technique. Although its intensity cannot compare with 2XXX and 7XXX series, it has more magnesium and silicon alloy properties. It also has excellent process ability, good welding characteristics and plating properties, good corrosion resistance and high toughness. When you process it, there will be no deformation exist and no defects occur because of its dense material. What’s more, it is easy being polished and coloring the film and it has very good oxidation effect.

Representative applications include aerospace fixing device, electric appliance fixing device, communication field, automatic machinery parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board solder vehicles and so on.

Packaging & Delivery

| Packaging Details: | Bulk packaging for 6061 aluminum of do as you required |

| Delivery Detail: | 30 days for 6061 aluminum after you confirm the order |

- Q: What is the difference between aluminum sheet and aluminum curtain wall? The cost is high!

- The upper and lower layers of the composite aluminum plate are high purity aluminum alloy plates, and the middle is a non-toxic low-density polyethylene (PE) core plate, also called an aluminum plastic plate, and the aluminum veneer is a single aluminum sheet. For appearance, the difference between the two is not large, but the color of aluminum plate is diverse. Price respect, curtain wall uses exterior wall board, aluminous plastic board price is in 100 yuan or so, 2.5mm thick aluminium single board price is in 240 the left and right sides, 3mm single board is more expensive.

- Q: Can aluminum sheets be custom cut to specific dimensions?

- Yes, aluminum sheets can be custom cut to specific dimensions. Aluminum is a versatile material that can be easily cut and shaped using various tools and techniques. This allows for precise customization to meet specific requirements and dimensions. Whether it is for industrial, commercial, or residential applications, aluminum sheets can be accurately cut to desired sizes, ensuring a perfect fit and functionality. Additionally, custom cutting aluminum sheets allows for flexibility in design and enables the creation of unique and tailored solutions.

- Q: What is the density of the 2A12 aluminum plate?

- 2.75 density. Shenzhen dexincheng metal plate is sold. Specifications are all complete.

- Q: Are the aluminum sheets suitable for manufacturing electrical enclosures?

- Indeed, aluminum sheets prove to be a suitable material for the production of electrical enclosures. Within the manufacturing industry, aluminum is widely utilized due to its versatility and numerous advantages. To begin with, aluminum possesses a unique combination of lightweight properties and strength, making it an ideal choice for constructing enclosures that require durability without the burden of excessive weight. Its strength-to-weight ratio surpasses that of many other metals, allowing for the creation of sturdy enclosures without unnecessary bulkiness. Moreover, aluminum exhibits exceptional resistance to corrosion, a crucial attribute for electrical enclosures that may encounter various environmental conditions, such as moisture, humidity, or corrosive elements. The natural oxide layer present on aluminum acts as a protective barrier, ensuring the enclosures' longevity and reliability. Additionally, aluminum possesses excellent electrical conductivity, a vital characteristic for electrical enclosures. This property facilitates efficient dissipation of heat generated by electrical components, effectively preventing overheating and potential damage to the enclosed devices. Furthermore, aluminum is highly machinable and can be easily molded into different shapes and sizes. This inherent flexibility enables manufacturers to customize the enclosures according to specific requirements, ensuring a perfect fit for the intended electrical components. Finally, when considering cost-effectiveness, aluminum proves to be a more economical choice compared to other metals such as stainless steel or copper. It strikes a balance between affordability and performance, making it an attractive option for the manufacturing of electrical enclosures. In conclusion, the lightweight nature, strength, corrosion resistance, electrical conductivity, machinability, and cost-effectiveness of aluminum sheets make them a highly suitable material for the production of electrical enclosures.

- Q: How is aluminum obtained from its ore?

- Aluminum is obtained from its ore through a process called Bayer's process. The ore, known as bauxite, is first crushed and then mixed with a hot solution of sodium hydroxide. This reaction causes the aluminum oxide in the ore to dissolve, forming sodium aluminate. The impurities in the ore, such as iron oxide and silica, remain insoluble. Next, the solution is filtered to remove the insoluble impurities, leaving behind a clear liquid containing sodium aluminate. This liquid is then cooled and treated with carbon dioxide gas, which converts the sodium aluminate into aluminum hydroxide. The aluminum hydroxide is then heated to form alumina or aluminum oxide. This process, known as calcination, involves heating the aluminum hydroxide at high temperatures to remove any remaining water and impurities. Finally, the alumina is mixed with a molten cryolite, which acts as a solvent, and then electrolyzed. Electrolysis involves passing an electric current through the molten mixture, causing the aluminum ions to migrate to the cathode, where they are reduced to form molten aluminum metal. The molten aluminum is then collected and cooled to solidify into ingots or other desired shapes. In summary, aluminum is obtained from its ore by first extracting the aluminum oxide using sodium hydroxide, followed by purification and conversion into alumina through calcination. The alumina is then electrolyzed using a molten cryolite, resulting in the production of molten aluminum metal.

- Q: does aluminum sheet has a function of magnetism isolating?

- copper sheet is better.

- Q: Can 101 aluminum sheets be anodized?

- Indeed, the anodization of 101 aluminum sheets is feasible. Anodization, which entails the formation of a safeguarding oxide layer on the aluminum's surface, enhances its resilience against corrosion and overall durability. This technique can be employed on different aluminum grades, including 101, to achieve desired finishes and offer added protection. The anodization process can be executed through diverse methods such as chromic acid anodizing, sulfuric acid anodizing, or hardcoat anodizing, depending on specific needs and desired outcomes. Consequently, it is assured that 101 aluminum sheets can undergo anodization procedures.

- Q: will it influence powder injection effect after wiping the oil contamination on the surface of aluminum sheet?

- the surface should be kept clean to avoid the influence of oil contamination.

- Q: This question asks if there are distinctions among various coatings applied to aluminum sheets.

- <p>Yes, there are significant differences between different types of coatings on aluminum sheets. These differences can include the purpose of the coating, such as for corrosion resistance, decorative effects, or enhanced durability. The materials used for the coatings can also vary, with options like anodizing, powder coating, or paint. Each type of coating has unique properties, such as resistance to weather, chemicals, or UV rays, and they can affect the surface appearance, weight, and cost of the aluminum sheet. The choice of coating often depends on the specific application and environmental conditions the aluminum sheet will be subjected to.</p>

- Q: Can aluminum sheets handle high temperatures?

- Yes, aluminum sheets can handle high temperatures. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), making it suitable for many high-temperature applications. Additionally, aluminum has excellent thermal conductivity, which allows it to quickly dissipate heat. This property makes aluminum sheets suitable for use in areas that require high-temperature resistance, such as engine components, heat exchangers, and oven linings. However, it is important to consider the specific alloy and thickness of the aluminum sheet, as different alloys may have varying temperature limits.

Send your message to us

2A12 5052 5083 6061 6083 7075 Aluminum Sheet Price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords