QM16125 ACCU-LOCK MACHINE VICE WITHOUT SWIVEL BASE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

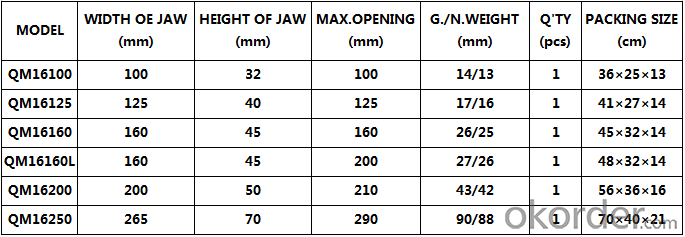

QM Series MachineVice

Performance and character:

1. It is one of main attachmentsfor milling、drillingmachine ,it is particularly suitable for the finishing of precision parts.

2. The accuracy of vice (parallelismand squareness) is 0.025mm/100mm.

3. The special segment in themovable jaw forces the vertical pressure downward when the horizontal pressureworks, so that this jaw does not lift the work piece.

4. Four positions allow extracapacity to change opening of jaw.

- Q: Numerical control milling machine vice school table

- After the workpiece is tightly stuck, it is possible to use the contact surface of the milling cutter and the workpiece on the plane at will, using the number of the display on the screen

- Q: Who knows the calculation and selection of the tongs?

- According to the requirement of dustproof protection and the requirement of interplay and pre-tightening, the appropriate structure can be chosen.

- Q: How to draw a vice assembly drawing

- The personal opinion determines the proportion, the reasonable layout, draws the outline of each view. Draw the main structural parts of the assembly and try to map the same parts of each view together.

- Q: What is the difference between the heavy duty and the light, how to choose the size of the tongs, usually 8 inches or 10 inches

- Also, don't know what to buy? There were a dozen, dozens, and a hundred, and more than two hundred, five hundred and six hundred, and I didn't know how much to buy. I'm a diy knife, black hey!

- Q: How does the UG set the motion simulation of the bench vice

- Please ask how this is done. After I emulated, even the screws moved together.I hope my answer will help you.

- Q: Several basic USES of bench vice

- Use of bench vice: the machine is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop.

- Q: Is the thread of a vice with a zigzag thread

- Inside is a t-nut, the letter "Tr". It is usually 4-6 pressure, single thread nut

- Q: What is the use of bench vice

- Essential tool vise for fitter, and fitter for the name of the source, because the bench most of the work is done on the vise, such as saws, file, chisel, and the components of the assembly and disassembly.

- Q: The structure of a vice

- Its structure consists of forceps, base, guide nut, screw and tongs. The active tongs glide through the guide track of the guide and the fixed clamp

- Q: Can the bench vice clamp the column bar? How to clip

- You can add a pair of live v-shaped pieces if you don't have them regularly If you often need to process the product of a round bar, it is recommended to remove the vice clamp and process the V groove, which will ensure the parallel and clamping of the workpiece

Send your message to us

QM16125 ACCU-LOCK MACHINE VICE WITHOUT SWIVEL BASE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches