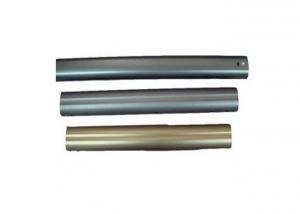

OEM Steel Turning Parts/Metal Stainless Steel Dowel Parts with Custom Made

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 1000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Material: Stainless steel

Precision: +/-0.5~+/-0.01mm

Machining type:Turning

OEM machining parts

Factory price

OEM custom made precision steel turning parts metal stainless steel dowel parts mechanical service

Description:

Quality Assurance: ISO9001: 2008

Precision: +/-0.05~+/-0.01mm

Strict quality control: 100% inspection during processing

Timely delivery: within 30 days, usually as to your quantity.

Accept low quantity with nice price and excellent quality.

Manufacture by customers’ drawings and specific requirement

Products Detail

Item |

Machining parts |

certification |

ISO9001:2008 |

Machining equipments |

CNC center, CNC milling machine, CNC turning machine, CNC lathes, lathe, 4 axis machine etc. |

Materials |

Aluminum, Steel, Stainless steel, Brass, Copper, Bronze, ABS, PC, PO, POM, Nylon, Teflon etc. |

Surface

finish |

Anodize, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving etc. |

Inspection

Equipment |

CMM, Projection, Calipers, Micro caliper, Thread Micro caliper, Pin gauge, Caliper gauge, Pass meter, Pass meter etc. |

Drawing

format |

AutoCAD, AutoCAD, Solid works, etc. |

- Q: Is this a standard part, or is it only required to buy the finished products from other factories, or do you want to design and size it yourself?

- According to the specifications of the tools you have used before

- Q: How to solve tooth strain of involute spline broach?

- Before broaching, you should check the verticality of the drawing fixture relative to the broach, otherwise the tooth side will easily strain

- Q: Hope to find a complex tool to do good enterprises, especially broaches do good, quality and Harbin first tool factory and other veteran manufacturers almost or almost no, but the price is relatively cheap, a lot of, thank you

- The tools of the Han River are made of broaches. What tool do you want, you can ask me.

- Q: Why is the tooth shape of broach oblique?

- It is with the direction of stress are related, when people use a hacksaw is thrown, so

- Q: 5.6 small caliber gun rifling production line with much manual broach

- The general value of deep rifling line diameter of the gun bore 2%. 5.72 or 5.75 arrows that broach,

- Q: Know how to draw Broaches for involute internal spline parameters

- To pull or spline spline, spline parameter is of course laane for internal spline broach;There are many factors in designing broaches, such as machine tool chucks, maximum broaching length, dimension and so on;General to broach company can do, they know how to do, need what parameter will provide.The spline joint is composed of inner spline and outer spline. The internal and external splines are all multi tooth parts, the splines on the inner cylinder surface are internal splines, and the splines on the outer cylinder surface are external splines. Obviously, the spline connection is the development of the number of flat key connections. Splines are standard structures.

- Q: I am currently in a lathe machinery factory, factory of broaching machine really curious.It is a hole with the kind of cylindrical broach broaching machine, after a day's work is down to a special knife Seurat with special machine tool grinding.Would you please tell me that the diameter of the broach is not smaller since he repaired it? Wouldn't it be possible to process the required size?

- Repair is the front edge of the broach, the blade has a wide blade. After grinding, only the edges become narrower and have nothing to do with the outer circle. Unless the grinding too much, will affect the outer diameter of the cutter tooth. However, the last 4-5 teeth of the broach are the correcting teeth for correcting the outer circle, so the sharpening broach has no influence on the final processing size.

- Q: Why don't carbon tools steel be used to make Broaches and gear cutters?

- Because of its hardness is too high, easy to crack, and if you do gear cutters and broaches, not only a few times will collapse.Therefore, Broaches and gear cutters must be cemented carbide.The carbon content of carbon tool steel is high, between 0.65-1.35%, and belongs to sub eutectoid, eutectoid or eutectoid steel. The carbon tool steel can get higher hardness and wear resistance after heat treatment, and the core has good toughness. The annealing hardness is low (not more than HB207), and the processing performance is good. However, when the working temperature reached 250 DEG C, the hardness and wear resistance of steel decreased rapidly, the hardness decreased to below HRC60, and the hardenability of this kind of steel was low. Larger tools can not be quenched (water quenched by 15mm), and when water is quenched, the hardness of the surface hardened layer differs greatly from that of the central part. Cause the tool to deform easily when it is quenched. In addition, the range of the quenching temperature is narrow and the temperature should be strictly controlled during quenching. Prevent overheating, decarburization and deformation.

- Q: Microcrystalline stone tile for broach can open it

- Microcrystalline stone cannot use the manual machine, so is not open, because its surface as glass, if the cutting or cutting machine, cutting machine with quick tow Microcrystalline stone to be cut, and then began to cut, but on the edge of some edge collapse phenomenon, may not very straight, if some local aesthetic requirements high, the best place to get professional processing of ceramic tile cutting, then the processing plant and a bottom, it will be better

- Q: CNC Lathe Feed base surface is floating, there is no good way to solve?

- With raw claws, or with two machine tools processing, a car base level, one to do the accuracy, try

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2012 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America South America Eastern Europe Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen,shenzhen shekou |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

OEM Steel Turning Parts/Metal Stainless Steel Dowel Parts with Custom Made

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 1000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords