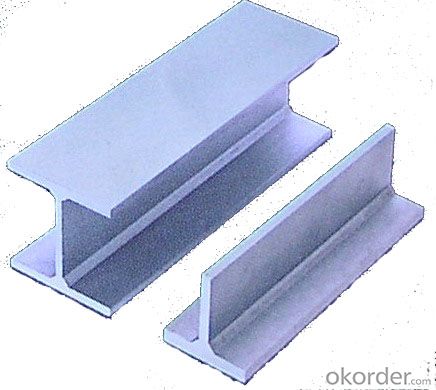

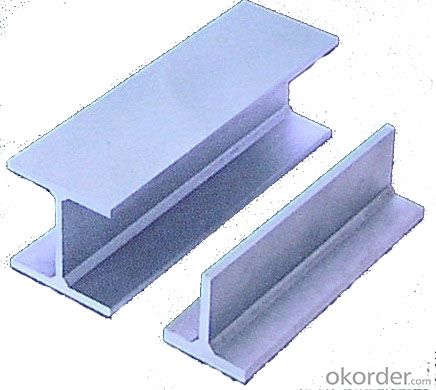

H Shape Steel Structure Steel Column Beam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

H Shape Steel Structure Steel Column Beam

Quick Details

Place of Origin: | Hebei, China (Mainland) | Grade: | Q235B | Technique: | Hot Rolled |

Thickness: | 100*100*6*8-900*300*16*28mm | Application: | construction | Length: | 6-12m |

Standard: | JIS | Flange Width: | 100-900mm | Flange Thickness: | 6-20mm |

Web Width: | 100-500mm | Web Thickness: | 5-15mm |

Packaging & Delivery

Packaging Details: | in bulk or in bundle or as the customers' requirements. |

Delivery Detail: | 30-45 days or according to your requirements |

Specifications

1.100*100*6*8mm-900*300*16*28mm

2. Standard: GB,JIS,ASTM

3. Length: 6m/9m/12m

4. Origin: Tangshan, Hebei province

Description

1.Grade: Q235B, Q235, Q345B, SS400, A36

2.Standard: JIS/ ASTM/ GB/ BS

3.Length: 5.8m, 6m, 12m, or as the customers’ requirements.

4.Usage:

(1).used for the plant, high-rise building construction

(2).used for the bridge, shipment building

(3).used for lifting and transportation machinery, equipment manufacturing base building

(4).used for the support, foundation pile manufacturing

5. Payment terms: 30% tt in advance, the balance against the LC or the copy of BL.

6.Package: in bulk or in bundle.

Tech Datas

ACCORDING TO STANDARD: JIS G3192 OR GB/T11263-2005 | |||

H beam Section sizenma(mm) | Weight (kg/m) | ||

Height×Breadth | Web thichness | Flange thichness | |

100×100 | 6 | 8 | 16.9 |

125×125 | 6.5 | 9 | 23.6 |

150×150 | 7 | 10 | 31.1 |

175×175 | 7.5 | 11 | 40.4 |

200×200 | 8 | 12 | 49.9 |

250×250 | 9 | 14 | 71.8 |

300×300 | 10 | 15 | 93.0 |

300×300 | 15 | 15 | 105.0 |

350×350 | 12 | 19 | 134.9 |

400×400 | 13 | 21 | 171.7 |

148×100 | 6 | 9 | 20.7 |

194×150 | 6 | 9 | 29.9 |

244×175 | 7 | 11 | 43.6 |

294×200 | 8 | 12 | 55.8 |

340×250 | 9 | 14 | 78.1 |

390×300 | 10 | 16 | 104.6 |

440×300 | 11 | 18 | 120.8 |

482×300 | 11 | 15 | 110.8 |

488×300 | 11 | 18 | 124.9 |

582×300 | 12 | 17 | 132.8 |

588×300 | 12 | 20 | 147.0 |

100×50 | 5 | 7 | 9.3 |

125×60 | 6 | 8 | 13.1 |

150×75 | 5 | 7 | 14.0 |

175×90 | 5 | 8 | 18.0 |

198×99 | 4.5 | 7 | 17.8 |

200×100 | 5.5 | 8 | 20.9 |

248×124 | 5 | 8 | 25.1 |

250×125 | 6 | 9 | 29.0 |

298×149 | 5.5 | 8 | 32.0 |

300×150 | 6.5 | 9 | 36.7 |

346×174 | 6 | 9 | 41.2 |

350×175 | 7 | 11 | 49.4 |

396×199 | 7 | 11 | 56.1 |

400×200 | 8 | 13 | 65.4 |

446×199 | 8 | 12 | 65.1 |

450×200 | 9 | 14 | 74.9 |

496×199 | 9 | 14 | 77.9 |

500×200 | 10 | 16 | 88.1 |

596×199 | 10 | 15 | 92.4 |

600×200 | 11 | 17 | 103.4 |

700×300 | 13 | 24 | 181.8 |

800×300 | 14 | 26 | 206.8 |

900×300 | 16 | 28 | 240.1 |

Products Picture

- Q: Are steel H-beams susceptible to bending or warping?

- Steel H-beams are not generally susceptible to bending or warping under normal circumstances. H-beams are designed to be structurally strong and are commonly used in construction and engineering projects where load-bearing capacity is essential. The H-shape of these beams provides excellent resistance against bending forces. However, it is important to note that extreme external forces or improper handling during transportation or installation can potentially cause bending or warping. Additionally, if the H-beams are not properly designed or manufactured to meet the required standards, they may be more susceptible to bending or warping. To ensure the structural integrity of steel H-beams, it is crucial to follow proper installation procedures, handle them with care, and use beams that meet industry standards and specifications. Regular maintenance and inspections are also important to identify any signs of bending or warping early on and address them promptly.

- Q: Are steel H-beams suitable for structures with large spans?

- Structures with large spans can be effectively supported by steel H-beams. H-beams, also known as I-beams or universal beams, have been specifically designed to evenly distribute the load along the beam's length, making them an ideal choice. The unique shape of the H-beam ensures exceptional structural integrity, enabling it to withstand heavy loads and resist bending or twisting. Moreover, steel H-beams possess a high strength-to-weight ratio, enabling them to support large spans without excessive weight. As a result, they have become a popular option for various structures, such as bridges, buildings, and industrial facilities, which necessitate extensive spans.

- Q: How do steel H-beams contribute to the overall sustainability of a structure?

- There are several ways in which the use of steel H-beams enhances the overall sustainability of a structure. To begin with, steel is an incredibly resilient material that can withstand harsh weather conditions, seismic activities, and fire, ensuring the enduring safety of the structure. This durability eliminates the need for frequent repairs or replacements, reducing resource consumption and waste generation. Moreover, steel H-beams possess a lightweight quality, unlike materials such as concrete or wood, thereby decreasing the overall weight of the structure. This lightweight characteristic facilitates more efficient transportation and construction processes, resulting in reduced energy consumption and carbon emissions during construction. Additionally, steel H-beams are highly recyclable, making them an ideal sustainable choice. At the end of a building's life cycle, these beams can be easily dismantled and transformed into new steel products without compromising their inherent properties. By recycling steel, the demand for new materials is diminished, conserving energy and decreasing greenhouse gas emissions associated with the production of fresh steel. Furthermore, steel H-beams offer design flexibility, enabling architects and engineers to create innovative and efficient structures. Their versatility allows for optimal material usage, minimizing waste and maximizing resource utilization. Moreover, this adaptability facilitates future modifications or expansions of the structure without extensive demolition or reconstruction. Lastly, steel H-beams possess a high strength-to-weight ratio, meaning they can support larger loads with less material. This efficiency in material usage reduces the overall environmental impact of the structure, as less steel is required to achieve the same structural integrity. Consequently, the use of steel H-beams in construction contributes to resource conservation and minimizes the carbon footprint of the building. In conclusion, the utilization of steel H-beams in construction enhances the overall sustainability of a structure due to their durability, lightweight nature, recyclability, design flexibility, and efficient material usage. By opting for steel H-beams, we can construct buildings that are not only safe and long-lasting but also environmentally friendly, conserving resources and reducing the carbon footprint of the construction industry.

- Q: How do you calculate the shear stress in steel H-beams?

- To calculate the shear stress in steel H-beams, you need to determine the applied shear force and divide it by the cross-sectional area of the beam's web. This will give you the shear stress acting on the beam.

- Q: How do steel H-beams perform in heavy snow loads?

- Steel H-beams perform exceptionally well in heavy snow loads due to their structural strength and durability. The H-shape design of the beam provides excellent load-bearing capabilities, allowing it to withstand the weight of accumulated snow without deformation or failure. Additionally, steel is known for its resistance to extreme weather conditions, including snow and ice, making H-beams a reliable choice for structures in snowy areas.

- Q: What is a steel H-beam?

- A steel H-beam is a structural beam made of steel with an H-shaped cross-section. It is commonly used in construction and engineering projects to provide support and stability. The H-beam's shape allows it to distribute weight evenly and withstand heavy loads, making it an ideal choice for various applications, such as building frames, bridges, and structural columns.

- Q: Are steel H-beams resistant to impact or vibration?

- Yes, steel H-beams are generally resistant to both impact and vibration due to their strong structural design and material properties.

- Q: How do you calculate the shear center of steel H-beams?

- To calculate the shear center of steel H-beams, you need to consider the beam's cross-sectional properties and geometry. This can be done using mathematical formulas or computer software designed for structural analysis. The shear center represents the point where the application of shear forces produces no twisting or bending of the beam, and its location can significantly affect the beam's structural behavior and stability.

- Q: What are the different types of steel H-beam connections used in bridge design?

- There are several different types of steel H-beam connections commonly used in bridge design. These connections are crucial in ensuring the stability and integrity of the bridge structure. Some of the most commonly used types of steel H-beam connections in bridge design include: 1. Welded Connections: This is the most common type of connection used in bridge design. Welded connections involve joining the H-beams together by melting and fusing the materials. Welded connections provide excellent strength and rigidity, making them suitable for various bridge types. 2. Bolted Connections: Bolted connections involve using high-strength bolts to connect the H-beams. These connections are relatively easy to install and provide flexibility for disassembly and maintenance. However, bolted connections may not offer the same strength and rigidity as welded connections. 3. Riveted Connections: Riveted connections were commonly used in older bridge designs but are rarely used in modern construction. Riveted connections involve using steel rivets to join the H-beams. While riveted connections provide good strength and durability, they can be time-consuming and expensive to install compared to other connection methods. 4. Moment Connections: Moment connections are used in situations where there is a need to transfer bending moments between the H-beams. These connections provide a high level of rigidity and are often used in bridge designs where large loads or forces are anticipated. 5. Shear Connections: Shear connections are designed to transfer shear forces between the H-beams. These connections are crucial in ensuring the stability and integrity of the bridge structure, particularly in areas where there is a significant horizontal force. 6. Composite Connections: Composite connections involve the combination of steel H-beams with other materials, such as concrete or timber. These connections provide the benefits of both materials, with the steel providing strength and the additional material offering other desirable properties like fire resistance or aesthetics. Overall, the choice of steel H-beam connection type depends on various factors, including the bridge design, load requirements, and construction methods. Each connection type has its own advantages and limitations, and the selection should be based on the specific needs and considerations of the bridge project.

- Q: Can steel H-beams be used for supporting airport hangars?

- Absolutely, airport hangars can be supported by steel H-beams. In construction, steel H-beams are widely utilized owing to their remarkable strength and durability. They are renowned for providing exceptional structural support and exhibiting resistance to heavy loads, thereby making them an optimal choice for bolstering substantial structures like airport hangars. The distinctive H shape of these beams facilitates efficient weight distribution, ensuring stability and preventing any possible structural failure. Furthermore, steel H-beams can be effortlessly fabricated and tailored to meet the specific requirements of the hangar in terms of size and weight capacity. All things considered, steel H-beams offer a dependable and economically viable solution for supporting airport hangars.

Send your message to us

H Shape Steel Structure Steel Column Beam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords