High Quality Hot Rolled Steel H Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Steel H-beam

1. Standard: GB

2. Grade: Q235 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

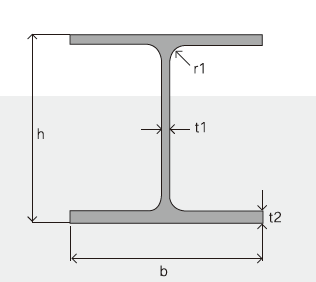

Category | model (height*width)/ (mm×mm) | Section size/mm | Cross-section area/cm2 | Theoretical Weight/(kg/m) | Moment of inertia/cm4 | radius/cm | Section modulus/cm3 | |||||||

H | B | t1 | t2 | r | Ix | Iy | ix | iy | Wx | Wy | ||||

HW | 100×100 | 100 | 100 | 6 | 8 | 8 | 21.59 | 16.9 | 386 | 134 | 4.23 | 2.49 | 77.1 | 26.7 |

125×125 | 125 | 125 | 6.5 | 9 | 8 | 30.00 | 23.6 | 843 | 293 | 5.30 | 3.13 | 135 | 46.9 | |

150×150 | 150 | 150 | 7 | 10 | 8 | 39.65 | 31.1 | 1620 | 563 | 6.39 | 3.77 | 216 | 75.1 | |

175×175 | 175 | 175 | 7.5 | 11 | 13 | 51.43 | 40.4 | 2918 | 983 | 7.53 | 4.37 | 334 | 112 | |

200×200 | 200 | 200 | 8 | 12 | 13 | 63.53 | 49.9 | 4717 | 1601 | 8.62 | 5.02 | 472 | 160 | |

200 | 204 | 12 | 12 | 13 | 71.53 | 56.2 | 4984 | 1701 | 8.35 | 4.88 | 498 | 167 | ||

250×250 | 244 | 252 | 11 | 11 | 13 | 81.31 | 63.8 | 8573 | 2937 | 10.27 | 6.01 | 703 | 233 | |

250 | 250 | 9 | 14 | 13 | 91.43 | 71.8 | 10689 | 3648 | 10.81 | 6.32 | 855 | 292 | ||

250 | 255 | 14 | 14 | 13 | 103.93 | 81.6 | 11340 | 3875 | 10.45 | 6.11 | 907 | 304 | ||

HM | 150×100 | 148 | 100 | 6 | 9 | 8 | 26.35 | 20.7 | 995.3 | 150.3 | 6.15 | 2.39 | 134.5 | 30.1 |

200×150 | 194 | 150 | 6 | 9 | 8 | 38.11 | 29.9 | 2586 | 506.6 | 8.24 | 3.65 | 266.6 | 67.6 | |

250×175 | 244 | 175 | 7 | 11 | 13 | 55.49 | 43.6 | 5908 | 983.5 | 10.32 | 4.21 | 484.3 | 112.4 | |

HN | 100×50 | 100 | 50 | 5 | 7 | 8 | 11.85 | 9.3 | 191.0 | 14.7 | 4.02 | 1.11 | 38.2 | 5.9 |

125×60 | 125 | 60 | 6 | 8 | 8 | 16.69 | 13.1 | 407.7 | 29.1 | 4.94 | 1.32 | 65.2 | 9.7 | |

150×75 | 150 | 75 | 5 | 7 | 8 | 17.85 | 14.0 | 645.7 | 49.4 | 6.01 | 1.66 | 86.1 | 13.2 | |

175×90 | 175 | 90 | 5 | 8 | 8 | 22.90 | 18.0 | 1174 | 97.4 | 7.16 | 2.06 | 134.2 | 21.6 | |

200×100 | 198 | 99 | 4.5 | 7 | 8 | 22.69 | 17.8 | 1484 | 113.4 | 8.09 | 2.24 | 149.9 | 22.9 | |

200 | 100 | 5.5 | 8 | 8 | 26.67 | 20.9 | 1753 | 133.7 | 8.11 | 2.24 | 175.3 | 26.7 | ||

250×125 | 248 | 124 | 5 | 8 | 8 | 31.99 | 25.1 | 3346 | 254.5 | 10.23 | 2.82 | 269.8 | 41.1 | |

250 | 125 | 6 | 9 | 8 | 36.97 | 29.0 | 3868 | 293.5 | 10.23 | 2.82 | 309.4 | 47.0 | ||

300×150 | 298 | 149 | 5.5 | 8 | 13 | 40.80 | 32.0 | 5911 | 441.7 | 12.04 | 3.29 | 396.7 | 59.3 | |

300 | 150 | 6.5 | 9 | 13 | 46.78 | 36.7 | 6829 | 507.2 | 12.08 | 3.29 | 455.3 | 67.6 | ||

350×175 | 346 | 174 | 6 | 9 | 13 | 52.45 | 41.2 | 10456 | 791.1 | 14.12 | 3.88 | 604.4 | 90.9 | |

350 | 175 | 7 | 11 | 13 | 62.91 | 49.4 | 12980 | 983.8 | 14.36 | 3.95 | 741.7 | 112.4 | ||

400×150 | 400 | 150 | 8 | 13 | 13 | 70.37 | 55.2 | 17906 | 733.2 | 15.95 | 3.23 | 895.3 | 97.8 | |

HT | 100×50 | 95 | 48 | 3.2 | 4.5 | 8 | 7.62 | 6.0 | 109.7 | 8.4 | 3.79 | 1.05 | 23.1 | 3.5 |

97 | 49 | 4 | 5.5 | 8 | 9.38 | 7.4 | 141.8 | 10.9 | 3.89 | 1.08 | 29.2 | 4.4 | ||

100×100 | 96 | 99 | 4.5 | 6 | 8 | 16.21 | 12.7 | 272.7 | 97.1 | 4.10 | 2.45 | 56.8 | 19.6 | |

125×60 | 118 | 58 | 3.2 | 4.5 | 8 | 9.26 | 7.3 | 202.4 | 14.7 | 4.68 | 1.26 | 34.3 | 5.1 | |

120 | 59 | 4 | 5.5 | 8 | 11.40 | 8.9 | 259.7 | 18.9 | 4.77 | 1.29 | 43.3 | 6.4 | ||

125×125 | 119 | 123 | 4.5 | 6 | 8 | 20.12 | 15.8 | 523.6 | 186.2 | 5.10 | 3.04 | 88.0 | 30.3 | |

150×75 | 145 | 73 | 3.2 | 4.5 | 8 | 11.47 | 9.0 | 383.2 | 29.3 | 5.78 | 1.60 | 52.9 | 8.0 | |

147 | 74 | 4 | 5.5 | 8 | 14.13 | 11.1 | 488.0 | 37.3 | 5.88 | 1.62 | 66.4 | 10.1 | ||

150×100 | 139 | 97 | 4.5 | 4.5 | 8 | 13.44 | 10.5 | 447.3 | 68.5 | 5.77 | 2.26 | 64.4 | 14.1 | |

142 | 99 | 4.5 | 6 | 8 | 18.28 | 14.3 | 632.7 | 97.2 | 5.88 | 2.31 | 89.1 | 19.6 | ||

150×150 | 144 | 148 | 5 | 7 | 8 | 27.77 | 21.8 | 1070 | 378.4 | 6.21 | 3.69 | 148.6 | 51.1 | |

147 | 149 | 6 | 8.5 | 8 | 33.68 | 26.4 | 1338 | 468.9 | 6.30 | 3.73 | 182.1 | 62.9 | ||

175×90 | 168 | 88 | 3.2 | 4.5 | 8 | 13.56 | 10.6 | 619.6 | 51.2 | 6.76 | 1.94 | 73.8 | 11.6 | |

171 | 89 | 4 | 6 | 8 | 17.59 | 13.8 | 852.1 | 70.6 | 6.96 | 2.00 | 99.7 | 15.9 | ||

175×175 | 167 | 173 | 5 | 7 | 13 | 33.32 | 26.2 | 1731 | 604.5 | 7.21 | 4.26 | 207.2 | 69.9 | |

172 | 175 | 6.5 | 9.5 | 13 | 44.65 | 35.0 | 2466 | 849.2 | 7.43 | 4.36 | 286.8 | 97.1 | ||

200×100 | 193 | 98 | 3.2 | 4.5 | 8 | 15.26 | 12.0 | 921.0 | 70.7 | 7.77 | 2.15 | 95.4 | 14.4 | |

196 | 99 | 4 | 6 | 8 | 19.79 | 15.5 | 1260 | 97.2 | 7.98 | 2.22 | 128.6 | 19.6 | ||

200×150 | 188 | 149 | 4.5 | 6 | 8 | 26.35 | 20.7 | 1669 | 331.0 | 7.96 | 3.54 | 177.6 | 44.4 | |

Usage & Applications of Hot Rolled Steel H-beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Steel H-beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Steel H-beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: What are the safety considerations when working with steel H-beams?

- Some safety considerations when working with steel H-beams include: 1. Proper lifting techniques: H-beams are heavy and require specialized equipment, such as cranes or forklifts, for lifting and moving. It is essential to follow proper lifting techniques to avoid injuries or accidents. 2. PPE (Personal Protective Equipment): Workers should wear appropriate PPE, including steel-toed boots, gloves, and helmets, to protect themselves from potential hazards like falling objects or sharp edges. 3. Secure storage and handling: H-beams should be stored and handled in a secure manner to prevent them from falling or causing accidents. Proper storage racks or supports should be used, and workers should avoid stacking beams too high or unevenly. 4. Inspection and maintenance: Regular inspection of H-beams is necessary to identify any signs of wear, deformation, or damage. Damaged beams should be immediately replaced to avoid potential structural failures or accidents. 5. Safe work environment: It is crucial to maintain a clean and organized work area to minimize tripping hazards. Workers should also be trained to recognize and avoid potential pinch points or other dangers associated with working around H-beams. 6. Communication and teamwork: Effective communication between workers is essential to ensure everyone is aware of their surroundings and the tasks being performed. Teamwork is crucial when maneuvering heavy H-beams to maintain balance and prevent accidents. By following these safety considerations, the risk of accidents or injuries can be significantly reduced, creating a safer working environment for all involved.

- Q: Are there any health concerns associated with Steel H-Beams?

- Yes, there are no direct health concerns associated with Steel H-Beams. However, it is important to handle and install them safely to prevent any injuries or accidents.

- Q: What are the different types of steel H-beam connections used in healthcare facilities?

- Healthcare facilities commonly use various types of steel H-beam connections to ensure the building's structural integrity and safety. These connections not only offer support but also withstand the dynamic loads and vibrations associated with healthcare operations. Some of the steel H-beam connections used in healthcare facilities include the following: 1. Welded connections: The most frequently used connection type in healthcare facilities involves welding the steel H-beams together, creating a strong and rigid connection. Welded connections are often utilized in areas requiring high load-bearing capacity, such as operating rooms or intensive care units. 2. Bolted connections: Bolted connections involve using bolts and nuts to join the steel H-beams together. This connection type allows for easier installation, inspection, and maintenance. Bolted connections are commonly found in non-critical areas of healthcare facilities, like corridors or administrative offices. 3. Moment connections: Designed to resist both vertical and horizontal forces, moment connections provide increased stability and rigidity to the structure. They are often used in areas subjected to lateral loads, such as emergency departments or MRI rooms. 4. Shear connections: Primarily used to transfer lateral loads between steel H-beams, shear connections resist shear forces and prevent beams from sliding or separating. Shear connections are typically employed in areas exposed to wind or seismic loads, like outpatient clinics or radiology departments. 5. Pinned connections: Pinned connections allow for rotation between steel H-beams. These connections are commonly used in areas where structural movements or deflections are expected, such as rehabilitation centers or physical therapy rooms. Pinned connections provide flexibility, allowing the structure to accommodate loads and movements without excessive stress. It is important to note that the selection of steel H-beam connections in healthcare facilities depends on factors such as specific building requirements, load conditions, and local building codes. Consulting structural engineers and architects during the design and construction process ensures appropriate selection and installation of the most suitable connections for healthcare facility structures.

- Q: Can steel H-beams be used in the construction of hospitals or healthcare facilities?

- Yes, steel H-beams can be used in the construction of hospitals or healthcare facilities. Steel H-beams are widely used in construction due to their strength, durability, and versatility. They provide excellent structural support and are commonly used in the construction of large buildings, including hospitals and healthcare facilities. In healthcare facilities, structural integrity and safety are of utmost importance, and steel H-beams meet these requirements. They can withstand heavy loads and provide stability to the building, ensuring the safety of patients, staff, and equipment. Steel H-beams also have a high resistance to fire and are non-combustible, which is crucial in ensuring the safety of healthcare facilities. Additionally, steel H-beams offer design flexibility. They can be easily customized to meet specific architectural requirements and can support different types of roofing, flooring, and wall systems. This versatility allows for efficient space planning and the creation of larger open areas, which is often necessary in healthcare facilities to accommodate medical equipment, patient rooms, and specialized areas such as operating rooms and laboratories. Moreover, steel H-beams have a long lifespan and require minimal maintenance. They are resistant to corrosion, pests, and decay, making them a reliable choice for healthcare facilities that need to remain operational over a long period. In summary, steel H-beams are suitable for the construction of hospitals and healthcare facilities due to their strength, durability, safety features, design flexibility, and low maintenance requirements.

- Q: Can steel H-beams be used in the construction of parking structures or garages?

- Yes, steel H-beams can definitely be used in the construction of parking structures or garages. H-beams are widely used in the construction industry for their strength, durability, and load-bearing capacity. They are capable of withstanding heavy loads and are suitable for constructing multi-story parking structures or garages. Additionally, steel H-beams offer various advantages such as their lightweight nature, which simplifies the construction process and reduces costs. They also provide flexibility in design, allowing for greater creativity in architectural layouts. Overall, steel H-beams are a popular choice for parking structure or garage construction due to their structural integrity and versatility.

- Q: Are steel H-beams suitable for structures with high wind loads?

- Yes, steel H-beams are suitable for structures with high wind loads. Steel H-beams are known for their high strength and rigidity, making them ideal for withstanding strong winds. Additionally, H-beams have a versatile design that allows for efficient load distribution, further enhancing their suitability for structures under high wind loads.

- Q: Can Steel H-Beams be used in architectural features or decorative elements?

- Certainly, architectural features or decorative elements can definitely utilize Steel H-Beams. Although primarily known for their structural strength and load-bearing capabilities in construction, H-Beams can also be employed in architectural designs to create distinctive and visually pleasing features. Architects and designers have the ability to integrate H-Beams into the overall aesthetics of a building, such as exposed beam ceilings, mezzanines, or open floor plans. The contemporary and industrial appearance of steel H-Beams can contribute a modern touch to any space. Furthermore, H-Beams can be utilized to fashion decorative elements like staircases, railings, pergolas, or even furniture pieces. Their sleek lines and durable nature make them suitable for both indoor and outdoor applications. In addition to their aesthetic appeal, steel H-Beams offer practical advantages. They possess fire-resistant properties, durability, and require minimal maintenance. Their structural integrity guarantees long-lasting performance and can endure heavy loads, which makes them an ideal choice for architectural features and decorative elements. All in all, Steel H-Beams present a versatile and visually appealing option for incorporating architectural features or decorative elements into a design. Their strength and durability, combined with their modern and industrial appearance, make them an outstanding option for both functional and aesthetic purposes in the field of architecture.

- Q: What are the common finishes available for steel H-beams?

- The common finishes available for steel H-beams include hot-dip galvanizing, primer painting, powder coating, and bare steel.

- Q: How do steel H-beams compare to timber beams in terms of durability?

- Steel H-beams are generally more durable than timber beams. Steel has a higher strength-to-weight ratio and is resistant to rot, insects, and fire. Steel beams can withstand heavy loads and have a longer lifespan compared to timber beams, which can be prone to decay, warping, and damage from pests.

- Q: What are the design considerations for steel H-beams in high-rise buildings?

- When it comes to designing steel H-beams for high-rise buildings, it is crucial to take several important factors into consideration. These factors include: 1. Load-bearing capacity: The primary purpose of steel H-beams is to bear and transfer the weight of the building. Therefore, the design must guarantee that the beams have enough load-bearing capacity to support the structure's weight. This involves considering the dead load (building's weight), live load (occupant and equipment loads), and wind load. 2. Structural stability: High-rise buildings are exposed to various forces, such as wind, seismic activity, and temperature fluctuations. Consequently, the design of H-beams must ensure the building's structural stability by incorporating adequate bracing and connections that can withstand these forces and prevent any potential collapses. 3. Fire resistance: In the event of a fire, it is essential for steel H-beams to maintain their structural integrity for a specified period, allowing occupants to evacuate safely. To enhance the beams' fire resistance, fire-resistant coatings or fireproofing materials can be applied. 4. Deflection and vibration control: High-rise buildings are susceptible to deflection and vibrations caused by wind, earthquakes, and dynamic loads. The design must consider the maximum allowable deflection and vibration limits to ensure the comfort and safety of occupants. Measures such as increasing beam depth, adding stiffeners, or incorporating dampening devices can be implemented to control deflection and vibration. 5. Fabrication and construction considerations: The design of steel H-beams should also take into account ease of fabrication and construction. This involves designing the beams with standard sizes and lengths to facilitate efficient fabrication and erection processes. Moreover, the connections between beams should be designed to ensure ease of installation while maintaining structural integrity. 6. Sustainability: In modern high-rise buildings, it is crucial to incorporate sustainable design principles. Therefore, the design of steel H-beams should aim to minimize material consumption and waste, optimize energy efficiency, and maximize the use of recycled materials. All in all, the design considerations for steel H-beams in high-rise buildings encompass ensuring load-bearing capacity, structural stability, fire resistance, deflection and vibration control, ease of fabrication and construction, and sustainability. By meticulously addressing these considerations, engineers can create high-rise buildings that are both safe and efficient, while also being sustainable.

1. Manufacturer Overview

| Location | Tangshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 230 Million |

| Main Markets | Mid East; Southeast Asia; Korea |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 500,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

High Quality Hot Rolled Steel H Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords