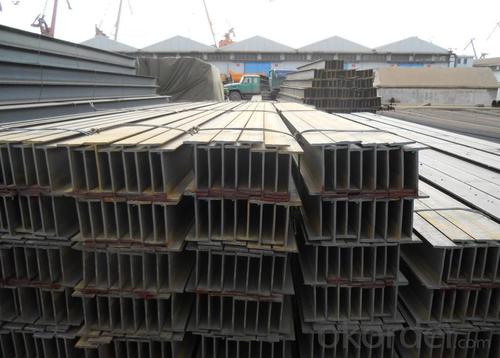

Prime Hot Rolled Mild Steel H Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 10000MT/month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Prime Hot Rolled Mild Steel H Beam

1. Standard: EN10034-1993 / EN10025-2004,

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

SIZE(MM) | KG/M |

100*100 | 16.9 |

125*125 | 23.6 |

150*75 | 14 |

150*150 | 31.1 |

148*100 | 20.7 |

198*99 | 17.8 |

200*100 | 20.9 |

248*124 | 25.1 |

250*125 | 29 |

300*150 | 36.7 |

298*149 | 32 |

200*200 | 49.9 |

294*200 | 55.8 |

346*174 | 41.2 |

350*175 | 49.4 |

244*175 | 43.6 |

175*175 | 40.4 |

Usage & Applications of Prime Hot Rolled Mild Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Prime Hot Rolled Mild Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Prime Hot Rolled Mild Steel H Beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel H-beams be used in the construction of stadiums or arenas?

- Yes, steel H-beams can be used in the construction of stadiums or arenas. Steel H-beams are widely used in the construction industry due to their strength, durability, and versatility. They are capable of supporting heavy loads and provide structural stability, making them suitable for large-scale projects such as stadiums and arenas. Steel H-beams are commonly used as the primary structural element in the construction of stadium roofs, grandstands, and other load-bearing components. Their ability to withstand high loads and resist deformation makes them ideal for supporting the weight of the stadium's roof structure, as well as accommodating the seating areas and other facilities within the stadium. Moreover, steel H-beams can be easily fabricated, allowing for efficient construction processes and reducing overall project time. Their modular design makes them adaptable to various design requirements and allows for flexibility in creating open and column-free spaces, which are often desired in stadiums and arenas. Additionally, steel H-beams offer excellent resistance to fire, corrosion, and other environmental factors, ensuring the long-term structural integrity of the stadium or arena. They also have a high strength-to-weight ratio, making them a cost-effective choice for large-scale projects. In conclusion, steel H-beams are a suitable and commonly used structural element in the construction of stadiums and arenas. Their strength, durability, versatility, and other advantageous properties make them an ideal choice for supporting the heavy loads and providing structural stability required in such large-scale constructions.

- Q: How do steel H-beams perform in terms of fire resistance?

- Steel H-beams perform well in terms of fire resistance. Due to their composition and structural design, steel H-beams have a high melting point and are less prone to deformation or collapse under high temperatures. This makes them highly resistant to fire and allows them to maintain their structural integrity for longer durations during a fire incident. The fire resistance of steel H-beams is further enhanced by the application of fireproofing materials, such as intumescent coatings or fire-resistant insulation. These materials create a protective layer on the surface of the beams, which expands when exposed to heat and forms an insulating barrier. This barrier slows down the transfer of heat to the steel, thereby increasing its fire resistance and preventing premature failure. Additionally, steel H-beams have excellent load-bearing capabilities, even at elevated temperatures. This means that in the event of a fire, they can continue to support the weight of the structure and prevent catastrophic collapses. This is particularly important in buildings and structures where fire safety is a critical concern, such as high-rise buildings, industrial facilities, or infrastructure projects. It is worth noting that while steel H-beams have good fire resistance, they are not entirely fireproof. In extremely high-temperature conditions, such as those found in intense fires, the steel may eventually weaken and lose its load-bearing capacity. However, compared to other building materials, steel H-beams offer superior fire resistance, making them a popular choice in construction projects where fire safety is a priority.

- Q: Can steel H-beams be used in curved or arched structures?

- No, steel H-beams are not typically used in curved or arched structures. These beams are designed to resist bending forces in a straight line and are not well-suited for curved or arched configurations. In such cases, other structural elements like curved steel beams or trusses are more commonly used to accommodate the desired shape.

- Q: Can steel H-beams be used for architectural purposes?

- Yes, steel H-beams can be used for architectural purposes. They are commonly used in construction to create structural support for buildings, bridges, and other architectural elements. The H-beams provide strength, stability, and versatility, making them suitable for various architectural designs and applications.

- Q: What are the different types of steel H-beam connections used in airport terminals?

- There are several types of steel H-beam connections commonly used in airport terminals, including bolted connections, welded connections, and moment-resisting connections. Bolted connections involve using bolts and nuts to join the H-beams together, offering ease of installation and disassembly. Welded connections involve permanently joining the H-beams using welding techniques, providing high strength and stability. Moment-resisting connections are designed to withstand bending moments and provide enhanced structural integrity, commonly used in areas with high wind loads or seismic activity. The specific type of connection used in airport terminals depends on factors such as the design requirements, structural loads, and construction techniques employed.

- Q: Are steel H-beams suitable for commercial or industrial buildings?

- Yes, steel H-beams are suitable for commercial or industrial buildings. They are known for their strength, durability, and load-bearing capabilities, making them a popular choice for constructing large structures. The H-shape provides excellent structural support, allowing for wide spans and heavy loads. Additionally, steel H-beams are versatile and can be fabricated to meet specific design requirements, making them an ideal choice for commercial and industrial applications.

- Q: Can steel H-beams be used in the construction of shopping centers or malls?

- Indeed, shopping centers or malls can benefit from the utilization of steel H-beams. This is because steel H-beams possess attributes such as strength, durability, and versatility, which make them a popular choice in commercial construction. By providing exceptional support to the structural framework of buildings, steel H-beams enable the creation of spacious and adaptable floor plans that are typically necessary for shopping centers and malls. Furthermore, these beams are capable of withstanding substantial loads and are highly resistant to fire and other potential dangers. Therefore, incorporating steel H-beams in construction endeavors guarantees the safety and enduring stability of shopping centers and malls.

- Q: What are the common sizes of steel H-beams available in the market?

- The market offers a diverse selection of steel H-beams with varying sizes to meet specific requirements and applications. Nevertheless, there are certain standard sizes that are commonly available. The height of these sizes typically falls within the range of 100mm to 1000mm, while the widths vary from 50mm to 500mm. As for the lengths, they also vary but are often found in standard sizes of 6 meters, 9 meters, or 12 meters. These commonly found sizes effectively address a wide range of construction and structural demands, enabling adaptability and flexibility in various projects.

- Q: How to process arc H steel?

- Small curvature component, is not the case, with the bending machine, about 600~800 yuan / ton, if the components or large curvature, according to the KONGGUOQING1, when considering the material, principle, or the use of thermal effect of heat bending, and bending frequency

- Q: Can steel H-beams be used in agricultural buildings?

- Yes, steel H-beams can be used in agricultural buildings. Steel H-beams are commonly used in construction due to their strength and durability. They can provide the necessary structural support and stability required for agricultural buildings. Additionally, steel H-beams are resistant to pests, rot, and fire, making them suitable for agricultural environments. Their versatility allows for various design options, accommodating different sizes and configurations of agricultural buildings. Overall, steel H-beams are a reliable and efficient choice for constructing agricultural buildings.

1. Manufacturer Overview

| Location | Tangshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 230 Million |

| Main Markets | Mid East; Southeast Asia; Korea |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 500,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Prime Hot Rolled Mild Steel H Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 10000MT/month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords