Hot Rolled H Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Hot Rolled H-Beam Steel

1. Standard: JIS G3101

2. Grade: SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

SIZE(mm) | DIMENSION(kg/m) |

100*100 | 16.9 |

125*125 | 23.6 |

150*75 | 14 |

150*150 | 31.1 |

148*100 | 20.7 |

198*99 | 17.8 |

200*100 | 20.9 |

248*124 | 25.1 |

250*125 | 29 |

300*150 | 36.7 |

298*149 | 32 |

200*200 | 49.9 |

294*200 | 55.8 |

346*174 | 41.2 |

350*175 | 49.4 |

244*175 | 43.6 |

175*175 | 40.4 |

294*200 | 55.8 |

298*201 | 64.4 |

346*174 | 41.2 |

350*175 | 49.4 |

400*200 | 65.4 |

396*199 | 56.1 |

450*200 | 74.9 |

446*199 | 65.1 |

340*250 | 78.1 |

500*200 | 88.1 |

300*150 | 36.7 |

Usage & Applications of Hot Rolled H-Beam Steel

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled H-Beam Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

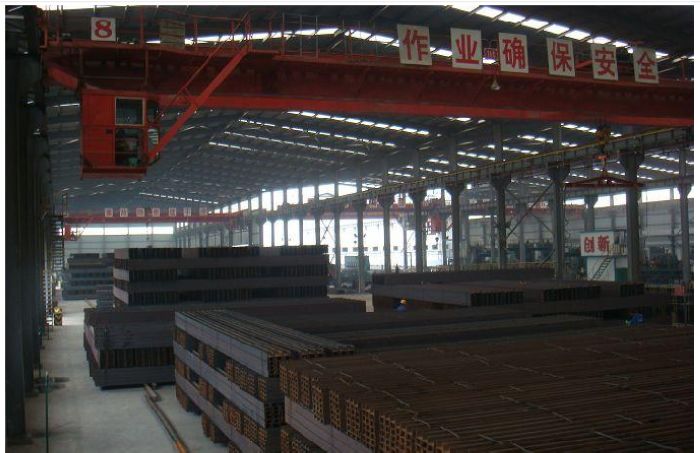

Production flow of Hot Rolled H-Beam Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: How do steel H-beams contribute to daylighting in buildings?

- Steel H-beams do not directly contribute to daylighting in buildings. Daylighting is the practice of utilizing natural sunlight to illuminate interior spaces, and it is typically achieved through the use of windows, skylights, or other transparent materials. Steel H-beams, on the other hand, are structural elements used for support in construction projects. While they play a crucial role in the overall structural integrity of a building, their primary function is not to enhance daylighting, but rather to provide stability and support.

- Q: Are steel H-beams resistant to chemicals or corrosive substances?

- Steel H-beams have a general resistance to chemicals and corrosive substances, thanks to the inherent properties of steel like its strength and durability. Steel is renowned for its ability to resist chemical reactions and corrosion, making it a suitable material for various industries where exposure to chemicals or corrosive substances is common. However, it is worth noting that the resistance of steel H-beams to chemicals and corrosive substances can vary depending on the specific type of steel used and the nature of the chemicals or corrosive substances involved. In extreme conditions or highly aggressive environments, steel may still be vulnerable to corrosion or chemical attack. To enhance the resistance of steel H-beams to chemicals and corrosive substances, it is possible to apply additional protective measures. These measures may include the use of coatings like galvanization or paint, which create a barrier between the steel surface and the surrounding environment. Regular maintenance and inspection are also crucial to promptly identify and address any signs of corrosion or chemical damage. In conclusion, while steel H-beams generally have resistance to chemicals and corrosive substances, it is important to consider the specific application and environment to determine the appropriate level of protection and maintenance needed.

- Q: What are the different methods of joining Steel H-Beams together?

- There are several methods of joining steel H-beams together, including welding, bolting, and using connectors such as steel plates or angle brackets.

- Q: How do steel H-beams connect to other structural elements?

- Steel H-beams can connect to other structural elements in a variety of ways depending on the specific design and engineering requirements of the project. One common method is through the use of bolts or welds. When connecting to other steel components, such as columns or beams, H-beams are often bolted together using high-strength bolts. These bolts are inserted through pre-drilled holes in the flanges (horizontal top and bottom sections) of the H-beam and then tightened with nuts. This creates a secure and rigid connection between the H-beam and the other structural elements. Welding is another method used to connect steel H-beams to other structural elements. In this case, the flanges of the H-beam are welded to the adjacent components, ensuring a strong and permanent connection. Welding is often preferred in situations where high load-bearing capacity and structural integrity are crucial. In addition to bolts and welds, other connection methods such as connectors or brackets can also be used depending on the specific requirements of the project. These connectors or brackets are often designed to provide additional strength and stability to the connection between the H-beam and other structural elements. It is important to note that the connection method used for steel H-beams depends on various factors, including the load-bearing capacity, structural design, and safety regulations. These factors are carefully considered by structural engineers and designers to ensure that the connection is strong, secure, and able to withstand the forces and loads imposed on the structure.

- Q: Are steel H-beams susceptible to fatigue?

- Indeed, steel H-beams are prone to fatigue. Fatigue occurs when a material weakens and breaks due to repeated cycles of stress. Just like any other structural components, steel H-beams can undergo fatigue if they are exposed to loads that repeat or fluctuate over time. These repeated stress cycles have the potential to create cracks in the material, which can eventually lead to failure. Factors such as the size, frequency, and duration of the applied loads, as well as the quality and condition of the steel, can influence how susceptible the beams are to fatigue. In order to prevent fatigue failure, engineers and designers must carefully analyze the anticipated loads and apply appropriate design standards. This may include incorporating safety margins, conducting fatigue analysis, and implementing thorough maintenance and inspection protocols.

- Q: What are the common uses of steel H-beams?

- Steel H-beams, also referred to as I-beams or W-beams, find extensive use in the field of construction and structural engineering owing to their strength and versatility. These beams serve various purposes such as providing structural support, forming building frames, constructing bridges, creating mezzanine floors, building industrial structures, functioning as support columns, and serving as foundational support in piling applications. Their ability to bear heavy loads and evenly distribute weight makes them an ideal choice for supporting large structures. In summary, steel H-beams play a crucial role in construction and structural engineering due to their robustness, adaptability, and capacity to support heavy loads.

- Q: Can steel H-beams be used for sports facilities?

- Yes, steel H-beams can be used for sports facilities. They provide structural support and stability, making them suitable for constructing various sports facilities like stadiums, arenas, or gymnasiums. The strength and durability of steel H-beams make them an ideal choice for withstanding heavy loads and ensuring safety in sports facilities.

- Q: What are the weight capacities of steel H-beams?

- The weight capacities of steel H-beams can differ based on various factors including the beam's size and dimensions, the grade of steel utilized, and the particular application or load demands. Typically, steel H-beams are engineered to endure substantial loads and possess significant weight capacities. They find frequent employment in construction and engineering ventures where structural robustness is paramount. To ascertain the weight capacity of a particular steel H-beam, it is crucial to refer to the manufacturer's specifications or seek guidance from a structural engineer capable of providing precise calculations based on the project's specific requirements.

- Q: Are steel H-beams suitable for power plants?

- Yes, steel H-beams are suitable for power plants. They offer excellent structural strength, durability, and load-bearing capacity, making them ideal for supporting heavy equipment and structures in power plants. Additionally, steel H-beams can withstand high temperatures and provide resistance against corrosion, making them well-suited for the demanding conditions typically found in power plant environments.

- Q: Are steel H-beams suitable for stadiums?

- Yes, steel H-beams are commonly used in the construction of stadiums and are considered suitable for this purpose. Steel H-beams offer several advantages that make them an ideal choice for stadium construction. Firstly, they provide excellent structural integrity and strength, allowing for large spans and high load-bearing capacities required in stadiums. This enables the construction of large open spaces without the need for excessive supporting columns, maximizing the viewing capacity for spectators. Additionally, steel H-beams are highly durable and resistant to various environmental factors, such as extreme weather conditions and seismic activities. This ensures the longevity and safety of the stadium structure. Moreover, steel H-beams can be easily fabricated and assembled, making the construction process efficient and cost-effective. Furthermore, steel H-beams allow for flexibility in design, enabling architects to create unique and visually appealing stadium structures. They can be used for various applications, including supporting roof structures, grandstands, and other stadium elements. In conclusion, steel H-beams are well-suited for stadiums due to their strength, durability, versatility, and cost-effectiveness. They provide the necessary structural support, while also allowing for efficient construction and aesthetically pleasing designs.

Send your message to us

Hot Rolled H Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords