GB Standard Steel H Beam 388mm-400mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Standard Steel H Beam 388mm-400mm with Good Quality For Sale:

1. Standard: GB Standard

2. Grade: Q235

3. Length: 12m

Size and mass:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 396*199*7.0 | 56.1 | 400*300*10.0 | 105 |

| 400*200*8.0 | 65.4 | 388*402*15.0 | 140 |

Usage & Applications of GB Standard Steel H Beam 388mm-400mm with Good Quality:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Production flow of GB Standard Steel H Beam 388mm-400mm with Good Quality:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

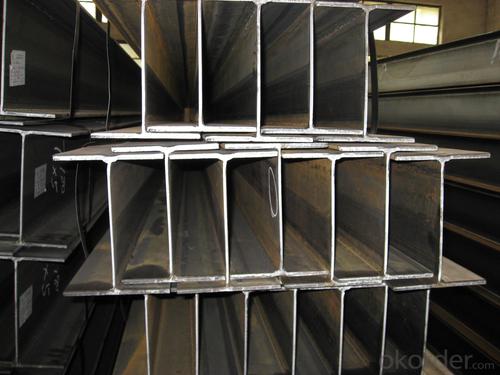

Images of GB Standard Steel H Beam 388mm-400mm with Good Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: How do steel H-beams perform in terms of impact resistance?

- Steel H-beams are known for their excellent impact resistance. The unique H-shaped cross-section provides a strong and rigid structure that can withstand heavy loads and impacts. This makes them highly suitable for applications where impact resistance is crucial, such as in the construction industry for supporting structures and bridges.

- Q: What are the different anti-corrosion treatments available for steel H-beams?

- There are several anti-corrosion treatments available for steel H-beams, including galvanizing, painting, epoxy coating, and powder coating. Galvanizing involves applying a layer of zinc coating to protect the steel from rust and corrosion. Painting involves applying a primer and topcoat to create a barrier between the steel and the environment. Epoxy coating is a type of paint that provides excellent corrosion resistance. Powder coating involves applying a dry powder to the steel and then baking it to create a durable and corrosion-resistant finish.

- Q: Can Steel H-Beams be used in sports or recreational facilities?

- Yes, Steel H-Beams can be used in sports or recreational facilities. Steel H-Beams are commonly used in the construction industry for their structural strength and durability. They provide excellent support for large spans and heavy loads, making them suitable for sports venues such as stadiums, arenas, and indoor sports facilities. Additionally, their versatility allows for creative and efficient designs in recreational facilities like gyms, fitness centers, and swimming pools.

- Q: What does "welding H" steel set "vertical" and "corrective processing" mean?

- Since the H steel web needs to be machined is 10 thick, it can be easily welded to the submerged welding machine, so there is no need to break the seamAfter blanking, use the crane to lift the plate to the erection machine one by one, and clamp. Start the set, set the machine, adjust the position of the three plates, and fix the spot weldingNote: the assembling machine is specially used to assemble the H steel machine, three plates, processing it can clamp type H steel H steel will start the machine, by the end of the assembling machine to roll to the other end, through assembling the machine when the door frame, can be used to adjust the assembling machine accurate three plate position, is a period of adjustment of rolling.After erection, the crane is welded to the welding platform and submerged arc weldingAfter welding, lift to straightening machine for straightening and correctingNote: the straightening effect correction principle: after welding flange may be not perpendicular to the web, using roller flat. Because H type steel may also be in the length direction is not straight, also can use the pressure roller is adjusted. The general steel processing plant of the straightening machine only in H flat slab steel width flat with length up straight. Straight up the length function of flame correction, flame correction, H steel with roasted curved, roasted red with water, due to thermal expansion and contraction, H type steel straight up. But it must have some experience to master the operation.

- Q: Do steel H-beams require additional bracing?

- Yes, steel H-beams often require additional bracing. H-beams are structural beams that are used in construction to support heavy loads. While they are designed to be strong and durable, certain factors such as the length of the beam and the load it will bear may necessitate the use of additional bracing. Bracing helps to provide lateral support and prevent the beam from buckling or bending under the weight it is carrying. Depending on the specific requirements and design of the structure, bracing can be added to H-beams through various methods such as diagonal braces, cross braces, or struts. It is important to consult with a structural engineer or a professional in the field to determine the specific bracing needs for steel H-beams in a given construction project.

- Q: How much is the weight of 200x200 H steel?

- 200*200 is the model, this model is divided into two specifications

- Q: How do steel H-beams compare to other structural beams, such as I-beams or W-beams?

- Steel H-beams are similar to I-beams and W-beams in that they are all widely used for structural purposes. However, H-beams offer distinct advantages over I-beams and W-beams. They have a wider flange, which provides greater stability and load-bearing capacity, making them ideal for heavier construction projects. Additionally, H-beams have a higher moment of inertia, allowing them to resist bending and deflection more effectively. Overall, steel H-beams are often preferred for their superior strength and durability compared to other structural beams.

- Q: Can Steel H-Beams be used in religious or worship facility construction?

- Certainly, the utilization of Steel H-beams in the construction of religious or worship facilities is possible. Indeed, Steel H-beams are widely employed in various construction projects due to their robustness, endurance, and adaptability. They are particularly well-suited for structures that necessitate extensive spanning beams or columns, rendering them an optimal selection for sizable religious or worship facilities such as churches, mosques, temples, or synagogues. Religious facility construction benefits greatly from the implementation of Steel H-beams. Firstly, they possess exceptional load-bearing capacity, permitting the creation of expansive and unobstructed spaces without the requirement of numerous supporting columns or walls. This proves especially advantageous in religious facilities as it enables unimpeded viewpoints and fosters a sense of unity and connection among devotees. Additionally, the use of Steel H-beams empowers architects and designers to incorporate distinctive and innovative designs, engendering visually captivating and awe-inspiring worship areas. Furthermore, Steel H-beams exhibit resistance towards fire, pests, and decay, making them a secure and enduring choice for religious structures. They also boast remarkable durability and necessitate minimal maintenance, guaranteeing the preservation of the facility's integrity and minimizing potential repair expenses over time. Moreover, steel is an environmentally sustainable and eco-friendly material. It is entirely recyclable, thereby presenting an environmentally conscious option for construction endeavors. By employing Steel H-beams in religious facility construction, organizations can contribute to a greener future by diminishing their carbon footprint. In conclusion, Steel H-beams represent an exceptional alternative for the construction of religious or worship facilities. Their strength, endurance, adaptability, and sustainability render them a dependable choice for establishing spacious, visually appealing, and long-lasting worship spaces.

- Q: Are steel H-beams suitable for use in the construction of airports or terminals?

- Yes, steel H-beams are suitable for use in the construction of airports or terminals. Steel H-beams are a commonly used structural element in construction due to their strength and durability. They are designed to withstand heavy loads and provide stability to structures. Airports and terminals require strong structural elements to support large spans, accommodate heavy equipment, and withstand dynamic loads from aircraft. Steel H-beams are capable of meeting these requirements, making them an ideal choice for such construction projects. Additionally, steel H-beams offer several advantages over other materials. They are fire-resistant, have a long lifespan, and require low maintenance. These properties make them a cost-effective option in the long run. Furthermore, steel H-beams can be easily fabricated and erected, allowing for efficient construction timelines. Their versatility allows for flexibility in design, enabling architects and engineers to create customized solutions for the specific needs of airports or terminals. In summary, steel H-beams are suitable for use in the construction of airports or terminals due to their strength, durability, fire resistance, and low maintenance requirements. They offer a cost-effective and efficient solution for creating stable and reliable structures that can withstand the demands of these facilities.

- Q: How do Steel H-Beams contribute to the overall occupant productivity of a building?

- Steel H-beams play a crucial role in enhancing the overall occupant productivity of a building in several ways. Firstly, these structural steel beams provide excellent support and stability to the building, ensuring a safe and secure environment for the occupants. This structural integrity creates a sense of comfort and peace of mind, allowing individuals to focus on their work without worrying about the building's stability. Furthermore, steel H-beams have high load-bearing capacity, which enables the construction of larger and more open spaces. This open layout promotes collaboration and communication among occupants, fostering a more productive and efficient work environment. The absence of obstructive columns or walls allows for flexible space planning, making it easier to accommodate different work styles and adapt to changing needs. In addition, steel H-beams have a high strength-to-weight ratio, which means they can withstand heavy loads while being relatively lightweight. This characteristic allows for the construction of taller and more spacious buildings without compromising on safety. The availability of ample natural light and views from higher floors can greatly benefit occupants by improving their overall well-being and productivity. Moreover, steel H-beams are highly durable and resistant to various environmental factors such as fire, earthquakes, and severe weather conditions. This durability ensures the longevity of the building and reduces the need for frequent renovations or repairs, minimizing disruptions to occupants' work routines. Lastly, steel H-beams can be easily fabricated and installed, reducing construction time and costs. This efficiency in construction translates into shorter project timelines, enabling occupants to move into the building sooner and start their operations faster, thus maximizing their productivity. Overall, the utilization of steel H-beams in the construction of buildings greatly contributes to the overall occupant productivity by providing structural stability, creating open and collaborative spaces, optimizing natural light and views, ensuring durability, and enabling faster construction.

Send your message to us

GB Standard Steel H Beam 388mm-400mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords