GB Standard Steel H Beam 440-500mm with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Standard Steel H Beam 440-500mm with High Quality For Sale:

1. Standard: GB Standard

2. Grade: Q235

3. Length: 12m

Size and Mass:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 450*200*9.0 | 74.9 | 496*199*9.0 | 77.9 |

| 440*300*11.0 | 121 | 500*200*10.0 | 88.2 |

Usage & Applications of GB Standard Steel H Beam 440-500mm with High Quality For Sale:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of GB Standard Steel H Beam 440-500mm with High Quality for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truc4. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

4. Delivered by container or bulk vessel

Production flow of GB Standard Steel H Beam 440-500mm with High Quality For Sale:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

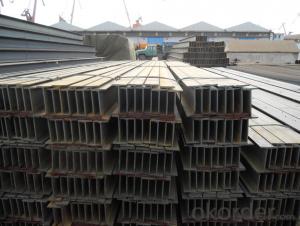

Images of GB Standard Steel H Beam 440-500mm with High Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can Steel H-Beams be used in data center or IT facility construction?

- Yes, Steel H-Beams can be used in data center or IT facility construction. Steel H-Beams are commonly used in commercial construction projects due to their structural strength and versatility. They provide excellent load-bearing capabilities, making them suitable for supporting heavy equipment and infrastructure in data centers and IT facilities. Additionally, Steel H-Beams are durable, fire-resistant, and can withstand extreme weather conditions, ensuring the safety and longevity of the facility. Their flexibility allows for easy customization and expansion, which is essential in dynamic environments like data centers. Overall, Steel H-Beams are a reliable and efficient choice for constructing data centers or IT facilities.

- Q: How do Steel H-Beams contribute to the overall natural disaster resilience of a structure?

- The overall natural disaster resilience of a structure is greatly enhanced by steel H-Beams. These beams are specifically designed to provide strength, stability, and flexibility, making them an ideal choice for withstanding extreme forces and impacts. Here are a few ways in which steel H-beams contribute to the overall natural disaster resilience of a structure: 1. Enhancing Structural Stability: Steel H-beams offer exceptional structural stability, making them highly resistant to the forces exerted by natural disasters such as earthquakes, hurricanes, and high winds. Their robust design ensures that the structure remains intact even under extreme conditions, reducing the risk of collapse and potential harm to occupants. 2. Supporting Heavy Loads: H-beams have a high load-bearing capacity, allowing them to support heavy loads and distribute the weight effectively throughout the structure. This feature is crucial during natural disasters, where the structure may experience additional loads due to strong winds, heavy rainfall, or debris impact. The ability of steel H-beams to withstand these loads enhances the overall resilience of the structure. 3. Flexibility and Energy Absorption: Steel H-beams possess excellent flexibility and ductility, enabling them to absorb and dissipate energy during seismic events or strong winds. This flexibility prevents the structure from becoming rigid and brittle, which can lead to failure. The ability of H-beams to flex and sway helps in dissipating the forces imposed by natural disasters, reducing the risk of structural damage. 4. Fire Resistance: Steel H-beams have inherent fire-resistant properties, which is crucial for natural disaster resilience. In the event of a fire caused by a disaster, steel beams do not combust or contribute to the spread of flames. This fire resistance allows occupants more time to evacuate safely and minimizes the risk of structural failure due to fire. 5. Longevity and Durability: Steel H-beams are highly durable and resistant to corrosion, ensuring their longevity and structural integrity even in harsh environmental conditions. This durability is vital for the long-term resilience of a structure against natural disasters, as it minimizes the need for regular repairs and replacements. In conclusion, steel H-beams significantly contribute to the overall natural disaster resilience of a structure by providing structural stability, load-bearing capacity, flexibility, fire resistance, and durability. Their ability to withstand extreme forces and impacts enhances the safety of occupants and reduces the risk of structural failure during natural disasters.

- Q: Can steel H-beams be used for railway bridges or overpasses?

- Yes, steel H-beams can be used for railway bridges or overpasses. Steel H-beams are commonly used in construction due to their high strength-to-weight ratio, making them suitable for supporting heavy loads. Railway bridges and overpasses require strong and durable materials to support the weight of trains, and steel H-beams are well-suited for this purpose. They provide structural stability, can withstand high loads and forces, and have the ability to span long distances. Additionally, steel H-beams are resistant to corrosion, which is important for structures exposed to the elements. Overall, steel H-beams are a popular choice for railway bridges and overpasses due to their strength, durability, and versatility.

- Q: 300 * 150 * 6.5 * 9 H steel is used as steel beam, span 6 meters, spacing 2 meters, laying steel plate, 15 cm soil

- The concrete strength grade of the slab does not know, the reinforcement does not know, the bearing capacity of the board can afford, it can not be calculated.

- Q: How do steel H-beams contribute to sustainable construction practices?

- Steel H-beams contribute to sustainable construction practices in several ways. Firstly, they are incredibly strong and durable, allowing for the construction of long-lasting structures that require minimal maintenance and repairs over time. This reduces the need for frequent replacements, minimizing waste and conserving resources. Additionally, steel H-beams can be recycled at the end of their lifespan, reducing the demand for new steel production and lowering the environmental impact associated with extracting and manufacturing raw materials. Lastly, their lightweight nature allows for efficient transportation and installation, reducing energy consumption during construction. Overall, steel H-beams offer sustainability benefits through their durability, recyclability, and energy-efficient characteristics.

- Q: Are steel H-beams suitable for commercial or industrial buildings?

- Yes, steel H-beams are commonly used in commercial and industrial buildings due to their numerous advantages. Firstly, H-beams provide excellent structural support and can withstand heavy loads, making them ideal for large-scale buildings such as warehouses, factories, and office complexes. Their high strength-to-weight ratio allows for the construction of longer spans and taller structures, maximizing usable space and minimizing the number of columns required. Additionally, steel H-beams are durable and resistant to various environmental factors, such as fire, moisture, and pests. They also offer flexibility in design, allowing for easy modifications and expansions in the future. Moreover, steel is a sustainable and recyclable material, making it an environmentally friendly choice for construction. Overall, steel H-beams are a reliable and cost-effective solution for commercial and industrial buildings, providing both structural integrity and design versatility.

- Q: Can steel H-beams be used in earthquake-resistant construction?

- Yes, steel H-beams can be used in earthquake-resistant construction. Steel is a strong and flexible material that can absorb and dissipate seismic energy during an earthquake. H-beams, specifically, provide additional stability and resistance to lateral forces, making them suitable for earthquake-resistant structures.

- Q: What are the different types of connections used for steel H-beams to concrete?

- Steel H-beams can be connected to concrete using different methods. Some of the most commonly used methods are as follows: 1. Embedding steel plates or angles in the concrete and welding the steel H-beam to them. This creates a strong and rigid connection, but it requires skilled labor and may take more time. 2. Using bolts to connect the steel H-beam to the concrete. This method is versatile and relatively easy, allowing for adjustments and easy disassembly if necessary. 3. Employing shear connectors, such as headed studs or profiled steel plates, in composite construction. These connectors are welded to the steel H-beam and embedded in the concrete to transfer shear forces between the two materials. 4. Utilizing specialized mechanical devices, like steel connectors or clamps, to join the steel H-beam to the concrete. These connections are often employed for temporary or removable structures due to their quick installation and removal capabilities. The choice of connection type depends on various factors, including project requirements, load capacity, construction method, and budget. It is crucial to consult with a structural engineer to determine the most suitable connection type for steel H-beams to concrete in a specific application.

- Q: Can steel H-beams be used in school gymnasium or sports facility construction?

- Yes, steel H-beams can be used in school gymnasium or sports facility construction. Steel H-beams are commonly used in construction due to their strength, durability, and versatility. They provide excellent support and structural integrity, making them suitable for large open spaces like gymnasiums and sports facilities. The H-shape design of the beam allows for a greater load-carrying capacity, making it an ideal choice for structures that require heavy loads. Additionally, steel H-beams are resistant to weathering, corrosion, and fire, ensuring the safety and longevity of the construction. Overall, steel H-beams are a reliable and efficient choice for school gymnasium or sports facility construction.

- Q: What is the process of galvanizing steel H-beams?

- The process of galvanizing steel H-beams involves immersing the beams in a bath of molten zinc to create a protective zinc coating on the surface. This process, known as hot-dip galvanizing, involves several steps including surface preparation, fluxing, galvanizing, and post-treatment to ensure a durable and corrosion-resistant coating. The H-beams are first cleaned, either through acid pickling or abrasive blasting, to remove any rust, scale, or other impurities. Next, the beams are fluxed to remove any remaining oxides and to promote adhesion of the zinc coating. The beams are then dipped into a bath of molten zinc, typically at a temperature of around 450 degrees Celsius, where a metallurgical bond is formed between the steel and the zinc. After galvanizing, the beams may undergo additional treatments such as quenching in water or air to cool and solidify the zinc coating, followed by inspection and post-treatment processes such as passivation or chromate conversion coating to enhance the appearance and improve corrosion resistance.

Send your message to us

GB Standard Steel H Beam 440-500mm with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords