GB Standard Steel H Beam 294mm-346mm with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Standard Steel H Beam 294mm-346mm with High Quality For Sale:

1. Standard: GB Standard

2. Grade: Q235

3. Length: 12m

Size and Mass:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 294*302*12.0 | 83.4 | 300*305*15.0 | 105 |

| 300*300*10.0 | 93.0 | 346*174*6.0 | 41.2 |

Usage & Applications of GB Standard Steel H Beam 294mm-346mm with High Quality For Sale:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of GB Standard Steel H Beam 294mm-346mm with High Quality for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truc4. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

4. Delivered by 40' GP/HP container or bulk vessel.

Production flow of GB Standard Steel H Beam 294mm-346mm with High Quality:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

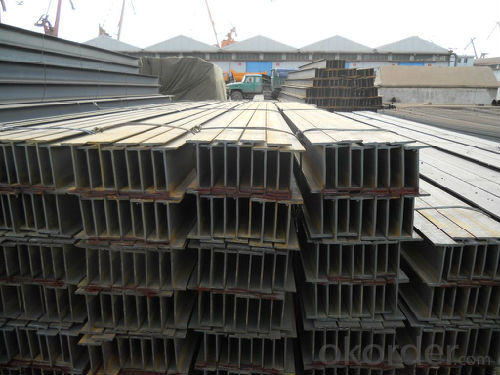

Images of GB Standard Steel H Beam 294mm-346mm with High Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Are steel H-beams suitable for supporting nuclear power plant facilities?

- Yes, steel H-beams are suitable for supporting nuclear power plant facilities. Steel H-beams are commonly used in construction due to their high strength and load-bearing capacity. They provide excellent structural support and stability, making them ideal for supporting the heavy equipment and structures found in nuclear power plants. Moreover, steel H-beams have a high resistance to fire, corrosion, and seismic activities, which are crucial characteristics for a facility with such sensitive operations. Additionally, steel H-beams can be manufactured to meet specific design requirements and can be easily modified or replaced if necessary. Overall, steel H-beams are a reliable and durable choice for supporting nuclear power plant facilities.

- Q: What are the factors to consider when selecting steel H-beams for a construction project?

- When selecting steel H-beams for a construction project, several factors need to be considered. These factors include the required load-bearing capacity, the length and size of the beams, the material grade and quality, the cost, and the supplier's reputation. It is important to ensure that the selected H-beams can withstand the expected loads and meet the project's structural requirements while considering the budget and ensuring a reliable and reputable supplier.

- Q: How do steel H-beams perform in areas with high humidity and chemical exposure?

- Steel H-beams are renowned for their exceptional strength and durability, making them a popular choice for various structural applications. However, when it comes to regions with high humidity and chemical exposure, there are several factors to take into account. In general, steel exhibits a high resistance to humidity and can endure prolonged exposure without significant degradation. The H-beams' design, characterized by wide flanges and a thick web, contributes to their ability to withstand moisture and corrosion. The flanges act as a protective barrier, preventing direct contact between the steel and the surrounding environment. Additionally, the steel used in H-beams is typically coated with a protective layer, such as galvanized or painted coatings, further augmenting its resistance to humidity and chemicals. Nevertheless, it is important to acknowledge that prolonged exposure to high humidity and certain aggressive chemicals can still impact the performance of steel H-beams. In highly corrosive environments, the protective coating may deteriorate over time, leaving the steel susceptible to rust and corrosion. This can compromise the structural integrity of the beams and impair their performance. To mitigate these risks, regular maintenance and inspections are imperative. In regions with high humidity and chemical exposure, it is advisable to implement a robust maintenance plan that incorporates periodic cleaning, inspection for any signs of corrosion, and the reapplication of protective coatings as necessary. Additionally, opting for stainless steel H-beams instead of carbon steel ones can offer even greater resistance to corrosion in such environments. In conclusion, while steel H-beams generally perform admirably in areas with high humidity and chemical exposure, proper maintenance and inspection are vital to ensure their long-term durability. By implementing a proactive maintenance plan, the structural integrity of the beams can be preserved, guaranteeing their continued performance in challenging environments.

- Q: What is the cost of steel H-beams compared to other structural materials?

- The cost of steel H-beams is generally higher compared to other structural materials due to their durability, strength, and versatility. However, their long lifespan and ability to withstand heavy loads make them a cost-effective choice in the long run.

- Q: What are the different design considerations when using steel H-beams in architectural projects?

- When using steel H-beams in architectural projects, several design considerations need to be taken into account. These considerations include the following: 1. Structural Stability: Steel H-beams are primarily used for their load-bearing capabilities. Therefore, it is crucial to ensure that the design accounts for the structural stability of the beams. This includes analyzing the load distribution, deflection, and stress on the beams to ensure they can safely support the intended loads. 2. Span and Size: The span and size of the steel H-beams play a significant role in determining their load-bearing capacity. Depending on the architectural project's requirements, the appropriate beam size and span should be selected to ensure structural integrity and prevent any potential issues, such as excessive deflection or bending. 3. Connection Details: The connection details between steel H-beams and other structural elements are essential for creating a robust and reliable architectural design. Proper connection design ensures the transfer of loads efficiently, minimizes stress concentrations, and allows for ease of construction and maintenance. 4. Fire Resistance: Steel H-beams have good fire-resistant properties, but in certain architectural projects, additional fire protection measures may be required to meet local building codes and safety regulations. These could include fire-resistant coatings or fireproofing materials to enhance the overall fire resistance of the structure. 5. Aesthetics and Design Integration: While steel H-beams are primarily structural elements, they can also contribute to the overall aesthetics of an architectural project. Integrating the beams into the design in a visually pleasing way can enhance the project's appeal. This may involve considerations such as exposing the beams or integrating them into architectural features, such as creating an industrial or modern aesthetic. 6. Sustainability: In today's architectural projects, sustainability is a crucial consideration. Steel is a highly sustainable material as it is recyclable and can be reused. Therefore, when using steel H-beams, it is important to ensure that the design maximizes the use of sustainable materials and minimizes waste. 7. Cost Efficiency: Lastly, the cost efficiency of using steel H-beams should be considered. The cost of materials, fabrication, transportation, and installation should be weighed against the project's budget and design requirements. Proper planning and coordination with structural engineers and contractors can help optimize cost efficiency without compromising safety or quality. In conclusion, design considerations for using steel H-beams in architectural projects include structural stability, span and size, connection details, fire resistance, aesthetics and design integration, sustainability, and cost efficiency. By addressing these considerations, architects can ensure the successful integration of steel H-beams in their designs, creating safe, visually appealing, and sustainable structures.

- Q: Can steel H-beams be used in the construction of data centers or IT facilities?

- Yes, steel H-beams can be used in the construction of data centers or IT facilities. Steel H-beams are commonly used in structural applications due to their strength, durability, and load-bearing capabilities. In the construction of data centers or IT facilities, where the primary focus is on housing and protecting sensitive computer equipment, steel H-beams provide a solid framework for the building's structure. Data centers and IT facilities require a robust infrastructure to support the weight of heavy equipment, such as servers, switches, and storage systems. Steel H-beams possess high tensile strength and can withstand heavy loads, making them ideal for creating a stable and secure environment for sensitive IT infrastructure. Additionally, steel H-beams offer versatility in design and construction. They can be easily fabricated and connected to create customized support systems for various components within the data center. This allows for flexible layouts and efficient use of space, which is essential in data center construction. Moreover, steel H-beams have excellent fire-resistant properties, providing an added layer of safety for a data center or IT facility. The inherent fire resistance of steel helps to protect the valuable equipment housed within the facility, minimizing the risk of damage or loss in the event of a fire. Overall, steel H-beams are a popular choice for the construction of data centers and IT facilities due to their strength, durability, load-bearing capabilities, versatility, and fire-resistant properties. Their use ensures the creation of a secure and well-supported environment for the critical IT infrastructure housed within these facilities.

- Q: Can steel H-beams be used in the construction of railway bridges?

- Yes, steel H-beams can be used in the construction of railway bridges. Steel H-beams are commonly used in bridge construction due to their high strength-to-weight ratio, which allows for longer spans and reduces the amount of material needed. They are also more resistant to corrosion, providing durability and longevity to the structure. Additionally, steel H-beams can be easily fabricated and connected, making them a cost-effective option for railway bridge construction.

- Q: How do you calculate the shear center of steel H-beams?

- To calculate the shear center of steel H-beams, you need to consider the beam's cross-sectional properties and geometry. This can be done using mathematical formulas or computer software designed for structural analysis. The shear center represents the point where the application of shear forces produces no twisting or bending of the beam, and its location can significantly affect the beam's structural behavior and stability.

- Q: What is the lifespan of steel H-beams?

- The lifespan of steel H-beams can vary significantly depending on various factors such as the quality of the steel, the environment in which they are used, and the maintenance and care they receive. Generally, well-maintained steel H-beams can have a lifespan of several decades or even longer.

- Q: How do steel H-beams compare to concrete beams in terms of cost and performance?

- Steel H-beams and concrete beams have different characteristics in terms of cost and performance. In terms of cost, steel H-beams tend to have a higher upfront cost compared to concrete beams. This is primarily because steel is a more expensive material than concrete. However, steel H-beams often have a longer lifespan and require less maintenance than concrete beams. This can lead to cost savings over the long term due to reduced repair and replacement costs. In terms of performance, steel H-beams offer several advantages over concrete beams. Steel has a higher strength-to-weight ratio, which means that steel beams can support larger loads with less material. This allows for greater design flexibility and potentially reduces the number of beams needed in a structure. Steel is also more resistant to fire and seismic activities, making it a preferred choice for structures in high-risk areas. Concrete beams, on the other hand, have their own advantages. Concrete is a readily available material and is often less expensive than steel in some regions. Concrete beams also have good resistance to corrosion and can withstand harsh environmental conditions. Additionally, concrete has excellent thermal properties, which can contribute to energy efficiency in buildings. In conclusion, while steel H-beams may have a higher initial cost compared to concrete beams, they offer superior performance in terms of strength, durability, and resistance to fire and seismic activities. However, concrete beams have their own advantages in terms of availability, cost, and thermal properties. The choice between steel H-beams and concrete beams ultimately depends on the specific requirements of the project, budget constraints, and local regulations.

Send your message to us

GB Standard Steel H Beam 294mm-346mm with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords