Hot Rolled Steel H Beam Q345

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

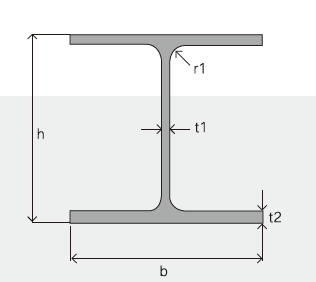

Specifications of Hot Rolled Steel H-beam Q345

1. Standard: JIS 3192

2. Grade: Q345,SS400 or Equivalent

3. Length: 10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

H x B (mm) | T1 | T2 | JIS Weight (kg/m) | GB Weight (kg/m) |

100*100 | 6 | 8 | 16.9 | 17.2 |

125*125 | 6.5 | 9 | 23.6 | 23.8 |

150*75 | 5 | 7 | 14 | 14.3 |

148*100 | 6 | 9 | 20.7 | 21.4 |

150*150 | 7 | 10 | 31.1 | 31.9 |

175*90 | 5 | 8 | 18 | 18.2 |

175*175 | 7.5 | 11 | 40.4 | 40.4 |

198*99 | 4.5 | 7 | 17.8 | 18.5 |

200*100 | 5.5 | 8 | 20.9 | 21.7 |

194*150 | 6 | 9 | 29.9 | 31.2 |

200*200 | 8 | 12 | 49.9 | 50.5 |

248*124 | 5 | 8 | 25.1 | 25.8 |

250*125 | 6 | 9 | 29 | 29.7 |

244*175 | 7 | 11 | 43.6 | 44.1 |

250*250 | 9 | 14 | 71.8 | 72.4 |

298*149 | 5.5 | 8 | 32 | 32.6 |

298*201 | 9 | 14 | 65.4 |

|

300*150 | 6.5 | 9 | 36.7 | 37.3 |

294*200 | 8 | 12 | 55.8 | 57.3 |

300*300 | 10 | 15 | 93 | 94.5 |

346*174 | 6 | 9 | 41.2 | 41.8 |

350*175 | 7 | 11 | 49.4 | 50 |

340*250 | 9 | 14 | 78.1 | 79.7 |

350*350 | 12 | 19 | 135 | 137 |

400*200 | 8 | 13 | 65.4 | 66 |

390*300 | 10 | 16 | 105 | 107 |

400*400 | 13 | 21 | 172 | 172 |

446*199 | 8 | 12 | 65.1 | 66.7 |

450*200 | 9 | 14 | 77.9 | 79.5 |

440*300 | 11 | 18 | 121 | 124 |

496*199 | 9 | 14 | 77.9 | 79.5 |

500*200 | 10 | 16 | 88.2 | 89.6 |

488*300 | 11 | 18 | 125 | 129 |

596*199 | 10 | 15 | 92.5 | 95.1 |

600*200 | 11 | 17 | 103.4 | 106 |

588*300 | 12 | 20 | 147 | 151 |

700*300 | 13 | 24 | 182 | 185 |

800*300 | 14 | 26 | 207 | 210 |

900*300 | 16 | 28 | 240.1 | 243 |

Usage & Applications of Hot Rolled Steel H-beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of Hot Rolled Steel H-beam Q345

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Steel H-beam Q345

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel angles be used in outdoor or corrosive environments?

- Yes, steel angles can be used in outdoor or corrosive environments. Steel angles are often made from low carbon steel or stainless steel, both of which have excellent corrosion resistance properties. Additionally, steel angles can be further protected from corrosion by applying coatings such as galvanization or painting. These protective coatings create a barrier between the steel and the corrosive elements in the environment, preventing rust and degradation. Therefore, steel angles are commonly used in outdoor structures, such as bridges, buildings, and industrial facilities, where they are exposed to moisture, saltwater, or other corrosive elements.

- Q: Can steel angles be used in the construction of agricultural buildings?

- Yes, steel angles can be used in the construction of agricultural buildings. Steel angles are commonly used as structural components for framing, bracing, and supporting various elements in agricultural buildings such as walls, roofs, and machinery. They provide strength, stability, and durability, making them suitable for withstanding the load and environmental conditions typically encountered in agricultural settings.

- Q: What is the maximum deflection allowed for a steel angle?

- The maximum deflection allowed for a steel angle depends on various factors such as the specific application, the load applied, and the desired safety factor. However, as a general guideline, the maximum deflection allowed for a steel angle is typically limited to 1/360th of its span length.

- Q: Can steel angles be bent or formed?

- Yes, steel angles can be bent or formed. Steel angles are commonly used structural elements that are made from steel and have an L-shaped cross-section. They can be bent or formed using various methods such as hot or cold bending, rolling, or press-braking. The specific method used will depend on factors such as the desired angle, radius of bending, and the thickness and type of steel being used. Bending or forming steel angles allows for the creation of different shapes and angles to suit specific structural or design requirements.

- Q: How do you determine the appropriate size of steel angle for a specific application?

- To determine the appropriate size of steel angle for a specific application, factors such as the load it needs to bear, the length of the span, the type of material being supported, and any applicable building codes or regulations should be considered. Structural engineers or professionals with expertise in steel construction can perform calculations and analysis to determine the required size of steel angle based on these factors.

- Q: Can steel angles be used in the construction of conveyor systems?

- Yes, steel angles can be used in the construction of conveyor systems. Steel angles are commonly used as structural components in conveyor systems due to their strength, durability, and versatility. They can be utilized to provide support, reinforcement, and stability to the conveyor structure. Steel angles can be easily welded or bolted together to create a rigid framework for the conveyor system. They can also be used to create adjustable legs or brackets to accommodate different conveyor heights or angles. Additionally, steel angles can be fabricated and customized to meet specific design requirements, making them a suitable choice for conveyor system construction.

- Q: What are the common defects or issues found in steel angles?

- There are several common defects or issues that can be found in steel angles, which can affect their structural integrity and performance. Here are some of the most frequently encountered: 1. Surface imperfections: Steel angles may have surface defects such as scratches, pits, or uneven coating. While these may not significantly affect the strength of the angle, they can impact its visual appearance and corrosion resistance. 2. Warping: Warping refers to the distortion or bending of the steel angle along its length. This defect can occur during the manufacturing process or due to improper handling or storage. Warped angles may not fit properly in applications where precise dimensions are required. 3. Flaws in dimensions: Steel angles should be manufactured to specific dimensions and tolerances. However, defects like undersized or oversized legs, unequal leg lengths, or inconsistent thickness can occur. These flaws can lead to problems during installation or compromise the structural integrity of the angle. 4. Lack of straightness: Steel angles should be straight along their length to ensure proper alignment and load distribution. However, they can sometimes exhibit a lack of straightness, commonly known as bowing or crooking. This defect can make it challenging to align angles accurately and may result in uneven stress distribution. 5. Internal cracks: Cracks within the steel angle are a significant concern as they can compromise its strength and load-bearing capacity. These cracks can occur during manufacturing due to improper cooling or quenching processes, or they can be a result of excessive stress or corrosion. Internal cracks are often not visible to the naked eye, making it crucial to perform non-destructive testing methods like ultrasound or magnetic particle inspection. 6. Corrosion: Steel angles are susceptible to corrosion, especially in environments with high humidity, moisture, or exposure to chemicals. Corrosion can weaken the structure and affect the angle's overall performance. Regular maintenance and proper coating or protective measures are necessary to prevent or minimize corrosion-related defects. It is essential to identify and address these defects or issues promptly to ensure the safety and reliability of steel angles in various applications, from construction and infrastructure to manufacturing and fabrication. Regular quality checks, adherence to industry standards, and appropriate maintenance practices can help mitigate these problems and ensure the longevity of steel angles.

- Q: Can steel angles be used for solar panel mounting?

- Yes, steel angles can be used for solar panel mounting. Steel angles are commonly used in solar panel mounting systems due to their strength, durability, and flexibility. They provide a sturdy and secure structure to support the weight of the solar panels and withstand environmental conditions such as strong winds and heavy snow loads. Steel angles also allow for easy adjustment and positioning of the solar panels to maximize sunlight exposure. Additionally, steel angles can be easily customized and fabricated to meet specific project requirements, making them a popular choice in the solar industry.

- Q: Can steel angles be used for temporary or removable structures?

- Yes, steel angles can be used for temporary or removable structures. Steel angles are versatile and commonly used in construction for various applications, including temporary or removable structures. They are often used as framing elements in scaffolding, support structures, and temporary partitions. Steel angles provide structural support and stability, making them suitable for temporary or removable structures that need to be strong and durable. Additionally, steel angles are easy to assemble and disassemble, allowing for convenient installation and removal of the temporary or removable structure.

- Q: Can steel angles be used as lintels or beams in construction?

- Yes, steel angles can be used as lintels or beams in construction. Steel angles are versatile structural elements that can provide support and strength to various types of structures. They are commonly used in construction projects for their ability to bear heavy loads and resist bending or warping. When used as lintels, steel angles are typically installed horizontally above doors and windows to distribute the weight of the structure above and prevent the opening from sagging. As beams, steel angles can be used to support floors, roofs, or other structural components. They are often preferred for their durability, versatility, and cost-effectiveness compared to other materials. However, it is important to consult with a structural engineer or construction professional to ensure that the specific steel angles being used are suitable for the intended application and meet the required building codes and standards.

Send your message to us

Hot Rolled Steel H Beam Q345

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords