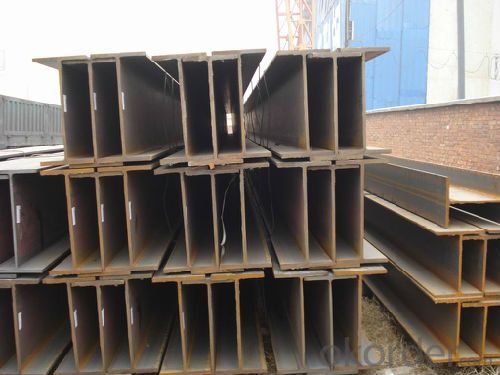

GB Standard Steel H Beam 428mm-498mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Standard Steel H Beam 428mm-498mm with Good Quality:

1. Standard: GB Standard

2. Grade: Q235

3. Length: 12m

Size and Mass:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 428*407*20.0 | 283 | 498*432*45.0 | 605 |

| 458*417*30.0 | 415 | 446*199*8.0 | 65.1 |

Usage & Applications ofGB Standard Steel H Beam 428mm-498mm with Good Quality:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of GB Standard Steel H Beam 428mm-498mm with Good Quality for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truc4. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

4. Delivered by container or bulk vessel

Production flow of GB Standard Steel H Beam 428mm-498mm with Good Quality:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

Images of GB Standard Steel H Beam 428mm-498mm with Good Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel H-beams be used in residential fence or gate structures?

- Yes, steel H-beams can be used in residential fence or gate structures. They are strong, durable, and provide excellent structural support, making them suitable for such applications.

- Q: How do steel H-beams perform in bridge expansions or contractions?

- Steel H-beams are widely used in bridge construction due to their excellent performance during expansions or contractions. These beams have high tensile strength and flexibility, allowing them to withstand the forces caused by temperature variations. As the bridge expands or contracts due to temperature changes, the steel H-beams can adjust their shape accordingly without compromising the structural integrity of the bridge. This ability to accommodate thermal movements makes steel H-beams an ideal choice for bridges, ensuring their stability and longevity over time.

- Q: What are the fire resistance properties of steel H-beams?

- Steel H-beams have excellent fire resistance properties due to their high melting point and low thermal conductivity. They can withstand extreme heat for a prolonged period without losing their structural integrity, making them a reliable choice for fire-resistant construction.

- Q: Can steel H-beams be used in museum or art gallery construction?

- Yes, steel H-beams can be used in museum or art gallery construction. They are a common choice for structural support due to their strength, durability, and ability to support heavy loads. Steel H-beams can provide the necessary stability and structural integrity required for large open spaces, allowing for flexible and creative design possibilities in museum or art gallery construction.

- Q: Specification for splicing length specification of H steel in steel structures

- Flange welding H steel joint seam spacing spell and the web, not less than 200mm. of flange splicing length should not be less than 600mm

- Q: How do steel H-beams perform in high winds?

- Steel H-beams are designed to have excellent strength and structural integrity, making them highly resistant to high winds. Their shape allows for efficient distribution of wind load, minimizing the risk of bending or structural failure. Consequently, steel H-beams perform exceptionally well in high winds, providing stability and ensuring the overall safety and durability of structures.

- Q: What's the difference between hot rolled H steel and welded H? Is it the same weight?

- Stable performance and good internal organization. Due to continuous casting from smelting to rolling, steel production than hot-rolled H steel process requirements, equipment capacity, control level, detection means is high, so the welding of H steel internal organization, chemical composition, various properties (mechanical properties, process performance indicators are reliable and stable etc.).

- Q: What are the design considerations for steel H-beams in earthquake-prone regions?

- The primary focus when designing steel H-beams in earthquake-prone regions is to ensure their structural integrity and resistance to seismic forces. Here are some important factors to consider: 1. Choosing the right material: The selection of steel grade is crucial in order to withstand seismic forces. High-strength steel, like ASTM A992 or A572 Grade 50, is commonly used for H-beams in earthquake-prone areas due to its superior strength and ductility. 2. Calculating beam size and shape: It is important to carefully calculate the dimensions of H-beams to ensure they can carry sufficient load and resist bending and buckling during seismic events. The beam's depth, flange width, and thickness are determined based on the expected loads and the seismic design requirements of the building. 3. Designing strong connections: The connections between H-beams and other structural elements must be designed to effectively resist seismic forces. Special attention is given to the moment connections at beam-column joints, as these areas experience concentrated forces during earthquakes. Strong and ductile connections, like extended end-plate connections or moment-resisting frames, are often used. 4. Prioritizing ductility and redundancy: The design of H-beams in earthquake-prone regions emphasizes the importance of ductility and redundancy. Ductility allows the steel members to deform and absorb energy during seismic events, while redundancy ensures that the structure can redistribute loads and maintain stability even if some elements fail. 5. Implementing bracing and reinforcement techniques: Proper bracing and reinforcement are essential to enhance the overall stiffness and stability of H-beam structures in earthquake-prone areas. Lateral bracing systems, such as diagonal braces or shear walls, are commonly used to reduce lateral sway and increase resistance to seismic forces. 6. Adhering to seismic design codes and regulations: It is crucial to comply with local building codes and seismic design regulations in earthquake-prone regions. Designers must be familiar with the specific requirements and guidelines provided in these codes to ensure that H-beam structures are adequately designed and constructed to withstand seismic events. 7. Conducting seismic analysis and testing: Before construction, structural engineers perform detailed seismic analysis and testing to evaluate the behavior and response of H-beams under earthquake loading. This analysis helps determine appropriate design parameters and identifies potential weaknesses or areas for improvement. Overall, the design considerations for steel H-beams in earthquake-prone regions revolve around ensuring structural integrity, resistance to seismic forces, and compliance with relevant building codes. By incorporating these considerations, engineers can create robust and safe structures capable of withstanding the challenges posed by earthquakes.

- Q: Are there any standards or codes that govern the use of steel H-beams?

- Yes, there are several standards and codes that govern the use of steel H-beams. These include industry standards such as the American Society for Testing and Materials (ASTM) standards, the American Institute of Steel Construction (AISC) codes, and the International Building Code (IBC). These standards and codes provide guidelines for the design, fabrication, and installation of steel H-beams to ensure their structural integrity and safety in various applications.

- Q: How do steel H-beams contribute to natural ventilation in buildings?

- Steel H-beams do not directly contribute to natural ventilation in buildings. However, they play an important role in the structural framework of the building, allowing for open and spacious designs that can incorporate elements like large windows, skylights, or operable vents. These architectural features, combined with proper building orientation and design, can enhance natural ventilation by allowing for the flow of fresh air and the expulsion of stale air, promoting a healthier and more comfortable indoor environment.

Send your message to us

GB Standard Steel H Beam 428mm-498mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords