Hot rolled Steel H-Beam

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

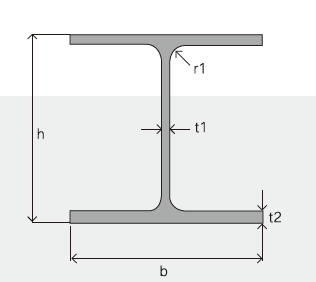

ecifications of Hot Rolled Steel H-beam

1. Standard: JIS 3192

2. Grade: SS400 or Equivalent

3. Length: 10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

|

H x B (mm) |

T1 |

T2 |

JIS Weight (kg/m) |

GB Weight (kg/m) |

|

100*100 |

6 |

8 |

16.9 |

17.2 |

|

125*125 |

6.5 |

9 |

23.6 |

23.8 |

|

150*75 |

5 |

7 |

14 |

14.3 |

|

148*100 |

6 |

9 |

20.7 |

21.4 |

|

150*150 |

7 |

10 |

31.1 |

31.9 |

|

175*90 |

5 |

8 |

18 |

18.2 |

|

175*175 |

7.5 |

11 |

40.4 |

40.4 |

|

198*99 |

4.5 |

7 |

17.8 |

18.5 |

|

200*100 |

5.5 |

8 |

20.9 |

21.7 |

|

194*150 |

6 |

9 |

29.9 |

31.2 |

|

200*200 |

8 |

12 |

49.9 |

50.5 |

|

248*124 |

5 |

8 |

25.1 |

25.8 |

|

250*125 |

6 |

9 |

29 |

29.7 |

|

244*175 |

7 |

11 |

43.6 |

44.1 |

|

250*250 |

9 |

14 |

71.8 |

72.4 |

|

298*149 |

5.5 |

8 |

32 |

32.6 |

|

298*201 |

9 |

14 |

65.4 |

|

|

300*150 |

6.5 |

9 |

36.7 |

37.3 |

|

294*200 |

8 |

12 |

55.8 |

57.3 |

|

300*300 |

10 |

15 |

93 |

94.5 |

|

346*174 |

6 |

9 |

41.2 |

41.8 |

|

350*175 |

7 |

11 |

49.4 |

50 |

|

340*250 |

9 |

14 |

78.1 |

79.7 |

|

350*350 |

12 |

19 |

135 |

137 |

|

400*200 |

8 |

13 |

65.4 |

66 |

|

390*300 |

10 |

16 |

105 |

107 |

|

400*400 |

13 |

21 |

172 |

172 |

|

446*199 |

8 |

12 |

65.1 |

66.7 |

|

450*200 |

9 |

14 |

77.9 |

79.5 |

|

440*300 |

11 |

18 |

121 |

124 |

|

496*199 |

9 |

14 |

77.9 |

79.5 |

|

500*200 |

10 |

16 |

88.2 |

89.6 |

|

488*300 |

11 |

18 |

125 |

129 |

|

596*199 |

10 |

15 |

92.5 |

95.1 |

|

600*200 |

11 |

17 |

103.4 |

106 |

|

588*300 |

12 |

20 |

147 |

151 |

|

700*300 |

13 |

24 |

182 |

185 |

|

800*300 |

14 |

26 |

207 |

210 |

|

900*300 |

16 |

28 |

240.1 |

243 |

Usage & Applications of Hot Rolled Steel H-beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of Hot Rolled Steel H-beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Steel H-beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: How do steel H-beams perform in structures subjected to vibration?

- Steel H-beams, due to their shape and material properties, perform exceptionally well in structures subjected to vibration. The H-shaped cross-section of these beams provides superior resistance against bending and torsional forces, making them an ideal choice for withstanding vibration loads. The structural rigidity and stiffness of steel H-beams allow them to effectively dampen vibrations and minimize the transmission of energy throughout the structure. This is particularly important in applications where vibrations can lead to fatigue, excessive deflection, or even structural failure. Moreover, steel is known for its high strength-to-weight ratio and excellent durability, which further enhances the performance of H-beams in vibrating environments. This allows them to endure dynamic loads without significant deformation or loss of structural integrity, ensuring the long-term stability and safety of the structure. In addition, steel H-beams can be designed and fabricated to meet specific vibration requirements based on the anticipated loads. By adjusting the beam's dimensions, material properties, and connection details, engineers can optimize its performance to effectively mitigate vibrations and maintain the structural integrity of the system. Overall, steel H-beams are highly effective in structures subjected to vibration. Their unique shape, material properties, and ability to dampen vibrations make them a reliable and preferred choice for various applications, including bridges, industrial buildings, and other structures where dynamic loads are a concern.

- Q: Can steel H-beams be used for railway bridges or overpasses?

- Certainly! Steel H-beams are a viable option for railway bridges or overpasses. They are widely used in construction owing to their remarkable strength-to-weight ratio, rendering them suitable for bearing heavy loads. The materials required for railway bridges and overpasses must be robust and enduring to support the weight of trains, and steel H-beams are well-suited for this purpose. They provide structural stability, possess the ability to endure significant loads and forces, and can span considerable distances. Moreover, steel H-beams possess resistance against corrosion, a crucial attribute for structures exposed to the elements. All in all, due to their strength, durability, and versatility, steel H-beams are a favored choice for railway bridges and overpasses.

- Q: Do steel H-beams require special maintenance?

- Special maintenance is not usually necessary for steel H-beams. Nevertheless, it is recommended to conduct regular inspections and maintenance to guarantee their structural soundness and long lifespan. This entails promptly addressing any signs of corrosion or damage, such as cracks or bends. Furthermore, it is important to keep the H-beams clean and clear of debris or excessive moisture in order to prevent corrosion and maintain their overall state. Ultimately, despite the renowned durability and strength of steel H-beams, regular maintenance is crucial to ensure their ongoing performance and safety.

- Q: Can steel H-beams be used in the construction of data centers or IT facilities?

- Indeed, data centers or IT facilities can utilize steel H-beams in their construction. These beams are frequently employed in structural applications due to their robustness, longevity, and ability to bear heavy loads. When erecting data centers or IT facilities, where the primary concern is safeguarding and accommodating delicate computer equipment, steel H-beams provide a sturdy framework for the building's structure. To support the weight of substantial equipment like servers, switches, and storage systems, data centers and IT facilities necessitate a resilient infrastructure. Steel H-beams possess remarkable tensile strength and can endure substantial loads, making them an ideal choice for establishing a stable and secure environment for sensitive IT infrastructure. Furthermore, steel H-beams offer versatility in design and construction. They can be easily fabricated and interconnected to form tailor-made support systems for various components within the data center. This enables flexible layouts and efficient utilization of space, which are vital aspects in data center construction. Moreover, steel H-beams exhibit excellent fire-resistant properties, providing an additional layer of safety for data centers or IT facilities. The inherent fire resistance of steel aids in safeguarding the valuable equipment housed within the facility, thereby minimizing the risk of damage or loss in the event of a fire. In summary, due to their strength, durability, load-bearing capabilities, versatility, and fire-resistant properties, steel H-beams are a favored option for constructing data centers and IT facilities. Their utilization guarantees the establishment of a secure and well-supported environment for the critical IT infrastructure housed within these facilities.

- Q: What are the different grades of steel used for manufacturing H-beams?

- Manufacturers commonly use different grades of steel to produce H-beams, each having distinct chemical compositions and mechanical properties that determine their suitability for various applications. Some commonly employed grades are as follows: 1. ASTM A36, a widely used low carbon steel grade, is highly favored for general structural purposes due to its exceptional weldability and machinability. 2. ASTM A572 exhibits greater strength and superior corrosion resistance compared to A36. It finds extensive use in applications requiring higher load-bearing capabilities, such as heavy construction and bridge building. 3. ASTM A992 is specially designed for wide-flange shapes like H-beams. It offers increased yield strength and enhanced ductility when compared to A36, making it ideal for structural applications that demand optimal performance. 4. ASTM A588 is renowned for its exceptional resistance to atmospheric corrosion. It is frequently employed in outdoor applications, including bridges and buildings located in harsh environments. 5. ASTM A709 primarily serves the purpose of constructing bridges and other infrastructure projects. With its high tensile strength, excellent toughness, and improved weldability, it is highly suitable for manufacturing H-beams in such applications. It is crucial to note that the selection of a specific steel grade relies on project requirements, including load-bearing capacity, environmental conditions, and other relevant factors. Seeking advice from a structural engineer or steel supplier can aid in determining the most appropriate grade for a given application.

- Q: What is the weight of a steel H-beam?

- The size and dimensions of a steel H-beam can cause variations in its weight. Typically, standard H-beams weigh between 33 pounds per foot and 330 pounds per foot. The weight is influenced by the beam's height, width, and thickness. To obtain an accurate weight measurement, knowledge of the precise dimensions of the H-beam under consideration is essential.

- Q: What does "welding H" steel set "vertical" and "corrective processing" mean?

- The steel plant produces H steel with a special machine to process a 500*300*12*10 H steel of a length of 12 meters

- Q: Can steel H-beams be used in retail or shopping mall construction?

- Yes, steel H-beams can be used in retail or shopping mall construction. Steel H-beams are commonly used in construction projects due to their strength, versatility, and cost-effectiveness. They provide structural support and can bear heavy loads, making them suitable for large-scale commercial buildings like retail or shopping malls.

- Q: Can steel H-beams be used as columns or posts?

- Yes, steel H-beams can be used as columns or posts in construction. The H-beam's structural design provides excellent load-bearing capacity and stability, making it suitable for vertical support applications like columns or posts.

- Q: How do steel H-beams perform in high-temperature applications?

- Due to their high structural strength and load-bearing capacity, steel H-beams find wide application in construction and engineering projects. However, exposure to high temperatures can negatively impact the performance of these beams. When subjected to elevated temperatures, steel H-beams undergo thermal expansion, resulting in expansion and deformation. This expansion diminishes the structural stability and integrity of the beams, compromising their load-carrying capacity. Consequently, they become less suitable for use in high-temperature environments. Furthermore, prolonged exposure to high temperatures weakens the steel material itself. As the temperature rises, the strength and hardness of steel decrease, further affecting the performance of H-beams. They may lose their ability to support heavy loads and may even deform or buckle under extreme heat conditions. To mitigate the adverse effects of high temperatures, various measures can be employed. One commonly used approach is the application of fire-resistant coatings, such as intumescent paints, to shield the steel H-beams from direct heat exposure. These coatings create a barrier that slows down the transfer of heat to the steel, thereby preserving their structural integrity to some extent. Additionally, selecting the appropriate steel grade is crucial for ensuring the performance of H-beams in high-temperature applications. Certain steel types, such as low-alloy steels or heat-resistant steels, are specifically designed to withstand elevated temperatures without significant loss in strength and stability. These specialized steel grades can be utilized in the manufacture of H-beams that are better suited for high-temperature environments. In conclusion, while steel H-beams possess excellent structural properties under normal conditions, their performance is compromised in high-temperature applications. It is important to consider the potential effects of thermal expansion, structural stability, and material strength when utilizing steel H-beams in environments with elevated temperatures. Proper precautions, such as the use of fire-resistant coatings and the selection of suitable steel grades, should be taken to ensure the safe and reliable operation of H-beams in such conditions.

1. Manufacturer Overview

| Location | Tangshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 230 Million |

| Main Markets | Mid East; Southeast Asia; Korea |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 500,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Hot rolled Steel H-Beam

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords