Hot Rolled Structural Steel H-beam JIS Standard all Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Structural Steel H-beam JIS Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Product Advantages:

OKorder's Structural Steel H-beam JIS Standard are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

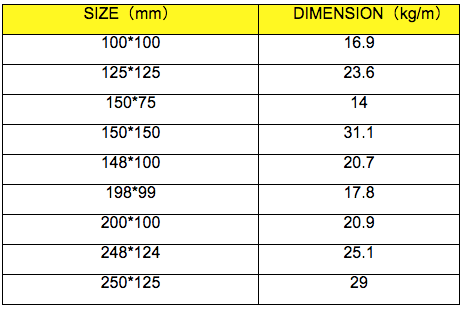

Specifications of Hot Rolled Structural Steel H Beam

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Structural Steel H Beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: What are the environmental impacts of steel H-beams?

- Steel H-beams have several environmental impacts, including the extraction and processing of raw materials, such as iron ore and coal, which contribute to air and water pollution. The manufacturing process also requires a significant amount of energy, resulting in greenhouse gas emissions. Additionally, the transportation and installation of steel H-beams contribute to carbon emissions. However, steel H-beams are durable and long-lasting, which can offset some of their environmental impacts by reducing the need for frequent replacements.

- Q: How are steel H-beams used in building bridges?

- The utilization of steel H-beams is prevalent in bridge construction due to their structural strength, durability, and ability to withstand heavy loads. These beams are specifically designed in the shape of an "H" to maximize strength and support when implemented horizontally as bridge girders. When erecting a bridge, steel H-beams are employed to establish the primary framework or superstructure. Typically positioned horizontally, these beams extend across the supports or piers of the bridge. To form a truss-like structure, they are frequently utilized in pairs with a central vertical column or pier. To ensure stability and rigidity, the H-beams are secured together through the utilization of welding or bolting techniques. This enables them to evenly distribute the weight of the bridge, thereby preventing excessive stress or strain on specific sections. Additionally, these beams are engineered to resist bending or deformation, rendering them ideal for spanning long distances. Furthermore, steel H-beams possess the capability to support various components of the bridge, such as decks, railings, and utility systems. By incorporating these beams into the overall bridge design, additional strength and stability can be achieved. Ultimately, steel H-beams are indispensable elements in bridge construction, as they provide the necessary structural integrity, strength, and load-bearing capacity required for safe and efficient transportation. The versatility and reliability of these beams have made them a favored choice among engineers and bridge builders worldwide.

- Q: Can steel H-beams be used for cantilever structures?

- Yes, steel H-beams can be used for cantilever structures. Cantilever structures are designed to have a projecting beam or member that is supported on only one end, with the other end free or unsupported. Steel H-beams are commonly used in construction due to their strength and load-bearing capabilities. They are well-suited for cantilever designs as they provide excellent structural support, minimizing deflection and ensuring stability. However, it is essential to consider the specific requirements of the cantilever structure and consult with a structural engineer to determine the appropriate size and strength of the H-beam needed to support the desired load and span.

- Q: What are the typical applications of steel H-beams?

- Steel H-beams are commonly used in construction and structural engineering for various applications. They are widely used in building frameworks, bridges, and platforms, providing support and stability in heavy load-bearing structures. H-beams are also utilized in the construction of industrial buildings and warehouses, as well as in the manufacturing and automotive industries for the fabrication of machinery and equipment. Additionally, they find application in the construction of high-rise buildings, stadiums, and infrastructure projects, where their strength and durability are essential for withstanding heavy loads and structural integrity.

- Q: What are the factors to consider when selecting steel H-beams for a project?

- When selecting steel H-beams for a project, there are several factors to consider. First, it is important to determine the load requirements of the project and ensure that the selected H-beams can withstand the anticipated weight and forces. Additionally, the dimensions and sizes of the H-beams should match the specifications and design requirements of the project. Material quality and durability are also crucial considerations, as the steel H-beams should be able to withstand corrosion, weather conditions, and other potential hazards. Lastly, cost and availability should be taken into account to ensure that the selected beams are within budget and readily accessible for the project.

- Q: What are the different installation methods for steel H-beams?

- There are several different installation methods for steel H-beams, depending on the specific application and structural requirements. Some of the commonly used methods include: 1. Welding: This is one of the most common methods for installing steel H-beams. It involves welding the beam to the supporting structure or connecting it to other beams or columns using welding techniques. Welding provides a strong and durable connection, but it requires skilled labor and proper welding procedures to ensure structural integrity. 2. Bolting: Another popular method is bolting, where the H-beam is connected to the supporting structure or other beams using bolts and nuts. This method offers flexibility as it allows for easy disassembly and reassembly, making it suitable for temporary structures or situations where modifications may be required. It is important to ensure proper bolt size, torque, and alignment to maintain structural stability. 3. Grouting: In some cases, H-beams may be embedded in concrete structures for added strength and stability. Grouting involves filling the space between the beam and the concrete with a high-strength, non-shrink grout to create a solid connection. This method is commonly used in construction projects where high load-bearing capacity is required. 4. Crane or hoist installation: In situations where the H-beam is too heavy or large to be installed manually, a crane or hoist can be used. This method involves lifting the beam into position and securing it using welding or bolting techniques as described above. It is important to adhere to proper lifting and rigging procedures to ensure safety and avoid any damage to the beam or surrounding structures. 5. Pre-engineered systems: Some manufacturers offer pre-engineered systems for steel H-beam installation. These systems typically include pre-cut and pre-drilled beams, along with detailed assembly instructions. This method simplifies the installation process and ensures accurate alignment and connection of the beams. It is important to consult with a structural engineer or construction professional to determine the most suitable installation method for steel H-beams based on the specific project requirements and local building codes.

- Q: How is the weight of H steel calculated?

- H section steel is a kind of economical section high efficiency profile with more optimized sectional area distribution and stronger weight ratio. It is named after the English letter "H". Because all the sections of H steel are arranged at right angles, H steel has been widely used in all directions for its advantages of high bending resistance, simple construction, cost saving and light weight.

- Q: Can steel H-beams be used in mezzanine floors?

- Indeed, mezzanine floors can incorporate steel H-beams. Owing to their robustness and longevity, steel H-beams find widespread application in the construction industry. They offer exceptional reinforcement and can endure substantial loads, rendering them ideal for mezzanine floors that serve as intermediary levels within a building. Steel H-beams enable the creation of a sturdy and secure framework for a mezzanine floor, thus enabling the provision of extra space and storage capacity within a structure.

- Q: How do steel H-beams contribute to waste reduction in construction?

- Steel H-beams contribute to waste reduction in construction by being highly durable and versatile, allowing for efficient use of materials. Their strength and load-bearing capacity enable the creation of more efficient structural designs, reducing the need for excessive materials and minimizing waste generation during the construction process. Additionally, steel H-beams can be easily recycled, further reducing waste in the construction industry.

- Q: What are the different design codes and standards for steel H-beams?

- Some of the different design codes and standards for steel H-beams include the American Institute of Steel Construction (AISC) 360, Eurocode 3, British Standards (BS) 5950, and the Canadian Standards Association (CSA) S16. These codes and standards provide guidelines and specifications for the design, fabrication, and construction of steel H-beams, ensuring structural integrity and safety.

Send your message to us

Hot Rolled Structural Steel H-beam JIS Standard all Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords