Structural Steel H-beam JIS Standard all Kinds of Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Structural Steel H-beam JIS Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Product Advantages:

OKorder's Structural Steel H-beam JIS Standard are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

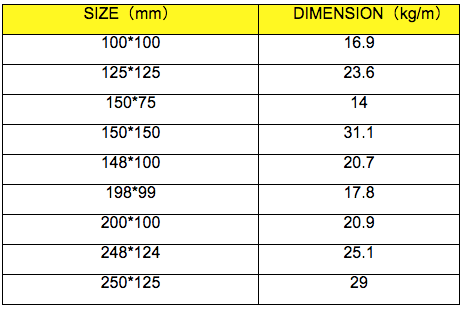

Specifications of Hot Rolled Structural Steel H Beam

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: How do steel H-beams perform in high-temperature environments?

- Due to their inherent properties and design, steel H-beams exhibit excellent performance in high-temperature environments. Their structural composition, combined with a high melting point, enables H-beams to maintain strength and integrity even when subjected to elevated temperatures. The thermal conductivity of steel plays a vital role in their performance. Steel possesses outstanding heat transfer properties, facilitating efficient heat distribution and dissipation throughout its structure. This characteristic prevents localized overheating, minimizing the risk of deformation or failure in high-temperature conditions. Furthermore, steel H-beams are often treated with fire-resistant coatings or insulation materials to further enhance their performance in high-temperature environments. These coatings or materials act as a protective barrier, shielding the steel from direct exposure to extreme heat and reducing the effects of thermal expansion. Moreover, the unique design of H-beams, which involves the cooperation of flanges and web to provide structural support, contributes to their ability to withstand high temperatures. The substantial flanges and web of the H-beams effectively distribute the load and resist bending, even under elevated temperature conditions. It is important to acknowledge that the performance of steel H-beams in high-temperature environments can be influenced by various factors, including the duration and intensity of heat exposure, as well as the specific grade and quality of the steel utilized. Therefore, consulting structural engineers and adhering to relevant building codes and standards is crucial to ensure the appropriate selection and installation of steel H-beams in high-temperature applications.

- Q: Can steel H-beams be used in hospital buildings?

- Yes, steel H-beams can be used in hospital buildings. They are commonly used in construction due to their strength, durability, and ability to support heavy loads. Steel H-beams provide structural integrity and are often used in critical areas such as columns and beams to ensure the stability and safety of the building.

- Q: H how long is the length of the steel section?

- There are two kinds of hot rolling and welding. The hot-rolled one is 12M, which is finished steel. The welding is made of heavy plate welding and there is no length limit

- Q: Can steel H-beams be used in the construction of schools or educational buildings?

- Certainly, schools or educational buildings can indeed make use of steel H-beams in their construction. The utilization of steel H-beams in construction is quite prevalent due to their commendable attributes of strength, durability, and versatility. These beams offer substantial structural support and possess the ability to withstand heavy loads, rendering them suitable for large-scale establishments like schools. Furthermore, the fabrication and installation of steel H-beams are relatively simple, thereby reducing both construction time and expenses. Furthermore, steel qualifies as a sustainable material since it is recyclable, thus making it an environmentally conscious choice for educational structures. In summary, incorporating steel H-beams into the construction of schools and educational buildings guarantees the creation of a secure and long-lasting edifice that complies with all necessary standards and requirements for such establishments.

- Q: What are the materials of H steel?

- The necessary grades can be marked behind said deoxidation methods of quality grades and symbols. The quality class symbols are A, B, C, and D respectively. Deoxidation method notation: F means boiling steel; B represents semi killed steel: Z indicates calm steel; TZ stands for special sedation steel; calm steel is not marked; Z and TZ are not standard. For example, Q235-AF indicates a class of rimmed steel.

- Q: How do steel H-beams contribute to the overall structural integrity of a building?

- The overall structural integrity of a building is greatly enhanced by the presence of steel H-beams. These beams play a crucial role in providing support and stability by evenly distributing the weight and load of the structure throughout its framework. One of the primary advantages of steel H-beams is their capacity to withstand heavy loads and resist bending or warping when under pressure. The unique shape of the H-beam, featuring wider flanges and a narrower web, grants it greater strength and durability compared to other structural materials. As a result, it is well-suited for supporting large spans and heavy loads, such as those found in bridges, skyscrapers, and industrial buildings. Furthermore, steel H-beams possess exceptional tensile strength, enabling them to withstand forces that attempt to pull them apart. This characteristic is particularly beneficial in areas prone to natural disasters like earthquakes or strong winds, as it helps the building endure these external forces and prevents collapse. The versatility of steel H-beams also allows for flexibility in design and construction. They can be easily fabricated and shaped into various lengths and sizes, making them suitable for different architectural styles and structural requirements. This adaptability is especially important in modern construction, where architects and engineers strive for innovative designs while ensuring safety and stability. Moreover, steel H-beams have a long lifespan and require minimal maintenance. They exhibit high resistance to corrosion, which helps prevent deterioration over time. This durability ensures that the building's structural integrity remains intact for many years, reducing the need for expensive repairs or replacements. In conclusion, steel H-beams make a significant contribution to a building's overall structural integrity by providing strength, stability, and load-bearing capacity. Their ability to withstand heavy loads, resist bending, and possess excellent tensile strength guarantees the safety and longevity of the structure. Additionally, their versatility in design and long lifespan make them a preferred choice in modern construction.

- Q: Can steel H-beams be used in the construction of railway bridges?

- Yes, steel H-beams can be used in the construction of railway bridges. Steel H-beams are commonly used in bridge construction due to their high strength-to-weight ratio, which allows for longer spans and reduces the amount of material needed. They are also more resistant to corrosion, providing durability and longevity to the structure. Additionally, steel H-beams can be easily fabricated and connected, making them a cost-effective option for railway bridge construction.

- Q: How do steel H-beams distribute load?

- Load distribution is achieved by steel H-beams through the utilization of their distinctive structural shape and material properties. H-beams are characterized by a horizontal top and bottom flange, connected by a vertical web in the center. This design enables the efficient distribution of loads by transferring them from the top flange to the web and then to the bottom flange, resulting in a balanced distribution of forces throughout the beam. The top and bottom flanges of H-beams are wider and thicker than the web, providing greater resistance to bending and torsional forces. When a load is applied to the beam, the top flange undergoes compression while the bottom flange undergoes tension. This distribution of forces helps the H-beam withstand bending and prevents it from collapsing under the weight of the load. Additionally, the vertical web in the center of the H-beam enhances stability and rigidity. It effectively resists shear forces that may act on the beam, preventing twisting or buckling. By connecting the flanges, the web ensures an even distribution of the load along the entire length of the beam, avoiding concentration in specific areas. The steel material used in H-beams is also pivotal in load distribution. Steel is renowned for its high tensile strength and durability, making it an ideal choice for structural applications. The strength of steel enables H-beams to bear heavy loads without deforming or failing. Moreover, steel possesses excellent stiffness and elasticity properties, guaranteeing that the H-beam maintains its shape and structural integrity under various loads. In conclusion, steel H-beams distribute load effectively through their unique shape and material properties. The horizontal flanges resist bending and tension forces, while the vertical web enhances stability and prevents twisting. The combination of these factors ensures efficient load distribution and the overall structural integrity of the system.

- Q: How do steel H-beams perform in mining and industrial facilities?

- Steel H-beams are widely used in mining and industrial facilities due to their exceptional performance and durability. These beams possess several key qualities that make them a preferred choice in these settings. Firstly, steel H-beams offer great structural strength and load-bearing capacity. They are designed to withstand heavy loads and provide a high level of stability, making them suitable for supporting large structures and equipment commonly found in mining and industrial environments. Moreover, steel H-beams have excellent resistance to corrosion and can withstand harsh conditions such as high humidity, extreme temperatures, and exposure to various chemicals. This resistance to corrosion ensures the longevity and reliability of the beams, reducing the need for frequent maintenance or replacement. Another advantage of steel H-beams is their versatility. They can be easily fabricated and customized to meet specific project requirements. This flexibility allows for seamless integration into different mining and industrial applications, such as supporting conveyor belts, constructing platforms, or creating structural frameworks. Additionally, steel H-beams provide enhanced fire resistance compared to other construction materials. In the event of a fire, these beams maintain their structural integrity for a longer period, allowing more time for evacuation and minimizing the risk of collapse. Furthermore, steel H-beams have a high recyclability rate, making them an environmentally friendly choice. At the end of their lifespan, these beams can be easily recycled and reused in other applications, reducing waste and promoting sustainability. In summary, steel H-beams are highly suitable for mining and industrial facilities due to their exceptional strength, durability, corrosion resistance, versatility, fire resistance, and recyclability. Their performance in these environments ensures the safety, stability, and longevity of structures and equipment, making them a preferred choice for various applications in these industries.

- Q: How do steel H-beams perform in extreme temperatures?

- Steel H-beams perform well in extreme temperatures due to their excellent thermal conductivity and high melting point. They exhibit minimal expansion or contraction, ensuring structural integrity even in extreme heat or cold conditions.

Send your message to us

Structural Steel H-beam JIS Standard all Kinds of Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords