Structural Steel H-Beam;

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

Specifications of Hot Rolled Structural Steel H Beam

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

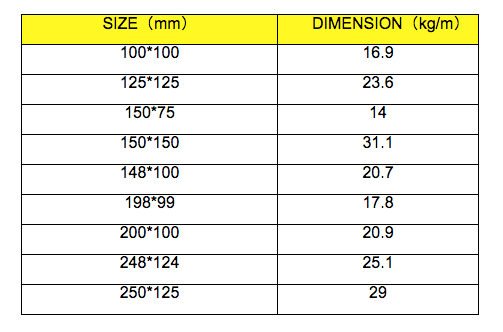

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Structural Steel H Beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel H-beams be used in utility infrastructure projects?

- Yes, steel H-beams can be used in utility infrastructure projects. Steel H-beams are commonly used in construction due to their strength and durability. They are particularly suitable for utility infrastructure projects because they can bear heavy loads and provide structural support. H-beams are often used in the construction of bridges, buildings, and other large structures, making them an ideal choice for utility infrastructure projects such as power plants, water treatment plants, and transmission towers. Additionally, steel H-beams are resistant to harsh weather conditions and can withstand natural disasters like earthquakes and hurricanes, making them a reliable choice for long-term utility infrastructure projects.

- Q: What are the typical applications of steel H-beams?

- Steel H-beams, also known as I-beams, are widely used in various construction and structural applications due to their unique shape and versatile properties. Some of the typical applications of steel H-beams include: 1. Building Construction: H-beams are commonly used in the construction of buildings and structures such as bridges, high-rise buildings, warehouses, and industrial facilities. They provide excellent structural support and stability, making them ideal for load-bearing applications. 2. Infrastructure Projects: H-beams are extensively used in infrastructure projects such as highways, railways, and airports. They are employed in the construction of supports for elevated roadways and rail tracks, as well as in the fabrication of large-scale structures like overhead gantries and pedestrian bridges. 3. Mezzanine Floors: Steel H-beams are often used in the construction of mezzanine floors, which are intermediate floors installed between the main floors of a building. H-beams allow for efficient space utilization by providing strong and sturdy support for the additional floor without the need for excessive columns or support structures. 4. Industrial Machinery and Equipment: H-beams find applications in the manufacturing and industrial sectors as well. They are used in the construction of heavy machinery, equipment frames, and supports for conveyor systems. The high strength and load-bearing capacity of H-beams make them suitable for handling heavy loads in industrial settings. 5. Shipbuilding: H-beams are commonly utilized in the shipbuilding industry for the construction of ship hulls, decks, and bulkheads. The robust nature of steel H-beams ensures structural integrity and stability, making them ideal for withstanding the harsh marine environment and heavy loads encountered by ships. 6. Automotive Industry: Steel H-beams also find applications in the automotive industry. They are used in the fabrication of vehicle frames, chassis, and suspension systems, providing strength and rigidity to ensure the safety and performance of automobiles. 7. Material Handling Equipment: H-beams are employed in the construction of material handling equipment such as cranes, forklifts, and hoists. Their structural strength enables them to handle and transport heavy loads efficiently and securely. Overall, the versatility, strength, and durability of steel H-beams make them suitable for a wide range of applications in various industries. They are a preferred choice for construction and structural projects where load-bearing capacity, stability, and reliability are crucial factors.

- Q: Can steel H-beams be used for supporting modular building systems?

- Yes, steel H-beams can be used for supporting modular building systems. They provide excellent structural support and can be easily integrated into the modular construction process.

- Q: How do steel H-beams contribute to sustainable transportation infrastructure?

- Steel H-beams make significant contributions to sustainable transportation infrastructure in various ways: 1. Long-lasting: Steel H-beams possess exceptional durability, enabling them to withstand heavy loads and harsh weather conditions. Consequently, their lifespan surpasses that of alternative materials, reducing the need for frequent replacements. Consequently, there is a decrease in material waste and energy consumption associated with transportation infrastructure maintenance and repairs. 2. Cost-efficient: Due to their longevity and low maintenance requirements, steel H-beams are a cost-effective choice. By minimizing the need for repairs and replacements, they result in considerable cost savings over the lifetime of transportation infrastructure projects. This efficient allocation of resources promotes sustainable budget management. 3. Recyclability: Steel ranks among the most recycled materials globally, and H-beams made from steel can be easily recycled at the end of their life cycle. This not only reduces the demand for new steel production but also minimizes the environmental impact associated with extracting and manufacturing new materials. By utilizing recycled steel, transportation infrastructure projects contribute to a circular economy and reduce their carbon footprint. 4. Design adaptability: Steel H-beams offer engineers design flexibility, enabling the creation of efficient and innovative transportation infrastructure solutions. Their high strength-to-weight ratio allows for the construction of lighter structures, reducing overall material consumption and transportation costs during construction. Furthermore, their ability to span long distances without intermediate support pillars decreases the need for additional materials and land use, promoting environmental friendliness. 5. Resilience: Steel H-beams exhibit exceptional resistance to natural disasters like earthquakes and hurricanes. This resilience ensures the safety and stability of transportation infrastructure, reducing risks associated with major events. By minimizing damage caused by natural disasters, steel H-beams contribute to the sustainable functioning and longevity of transportation networks. In conclusion, steel H-beams play a crucial role in establishing sustainable transportation infrastructure by offering durability, cost-efficiency, recyclability, design adaptability, and resilience. By incorporating these beams into construction projects, we can enhance the longevity, safety, and environmental friendliness of transportation networks, thus contributing to a more sustainable future.

- Q: Can steel H-beams be used for mezzanine floors?

- Yes, steel H-beams can be used for mezzanine floors. Steel H-beams are commonly used in construction for their strength and load-bearing capabilities. Mezzanine floors are typically added to existing structures to create additional usable space, and steel H-beams provide the necessary support for the floor. They can withstand heavy loads and distribute the weight evenly, making them suitable for mezzanine floor construction. Additionally, steel H-beams are durable and long-lasting, ensuring the stability and safety of the mezzanine floor.

- Q: What is the weight of a standard steel H-beam?

- The dimensions and specifications of a standard steel H-beam are what determine its weight, which can vary. Generally, a standard steel H-beam weighs around 33 pounds per linear foot. It is worth mentioning that the weight may differ based on the size and grade of the steel H-beam.

- Q: How do steel H-beams distribute load?

- Steel H-beams distribute load by transferring it evenly across the beam's flanges, which are the horizontal components, and the web, which is the vertical component. This design allows the beam to withstand and distribute heavy loads without bending or buckling under pressure.

- Q: How do steel H-beams contribute to green roof design?

- Steel H-beams contribute to green roof design by providing a strong and durable framework to support the weight of the green roof system. These beams are typically made from recycled steel, promoting sustainability. Additionally, their structural integrity allows for the installation of extensive green roofs, which help to reduce stormwater runoff, improve air quality, and enhance energy efficiency in buildings.

- Q: Can steel H-beams be used in residential deck or patio structures?

- Indeed, residential deck or patio structures can indeed utilize steel H-beams. The construction industry often favors steel H-beams due to their robustness and endurance. These beams can offer crucial support to decks and patios, particularly in regions where substantial loads or extended spans may be present. Steel H-beams possess resistance against warping, twisting, and shrinking, rendering them apt for outdoor structures that face diverse weather conditions. Moreover, steel H-beams can be readily tailored to meet precise design specifications, thus guaranteeing a secure and dependable residential deck or patio structure.

- Q: How do steel H-beams compare to timber beams in terms of sustainability?

- Steel H-beams and timber beams differ significantly in terms of sustainability. Steel H-beams are typically made from recycled steel, which reduces the demand for new steel production and minimizes the carbon footprint associated with manufacturing. Additionally, steel is a highly durable material, meaning that steel H-beams have a longer lifespan and require fewer replacements over time. This durability results in less waste generation and lower maintenance costs, making steel H-beams a more sustainable option in the long run. On the other hand, timber beams have their own sustainability advantages. Timber is a renewable resource, as trees can be replanted to replace those that are harvested. The production of timber beams also requires less energy compared to steel H-beams. Furthermore, the process of harvesting and manufacturing timber has a lower carbon footprint compared to steel production, as it produces fewer greenhouse gas emissions. However, timber beams have limitations in terms of durability and resistance to fire and moisture. They are prone to decay, insect damage, and warping, which can decrease their lifespan and increase maintenance and replacement needs. Additionally, the use of timber from unsustainable logging practices can contribute to deforestation and habitat destruction. In summary, while both steel H-beams and timber beams have sustainability benefits, steel H-beams have the advantage of being made from recycled materials, offering high durability, and reducing waste generation. Timber beams, on the other hand, are renewable, require less energy in production, and have a lower carbon footprint. Ultimately, the choice between steel H-beams and timber beams should consider factors such as the specific application, local availability of materials, and the overall environmental impact throughout the life cycle of the beams.

Send your message to us

Structural Steel H-Beam;

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords