Light Steel Frame Formwork with Plywood for Two Level Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 70000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

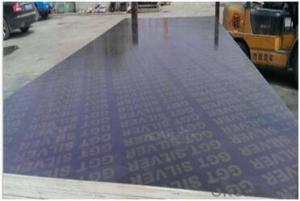

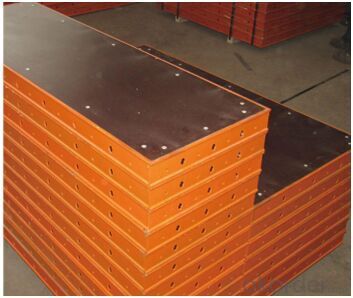

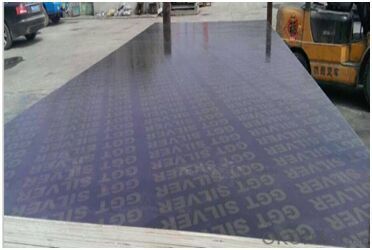

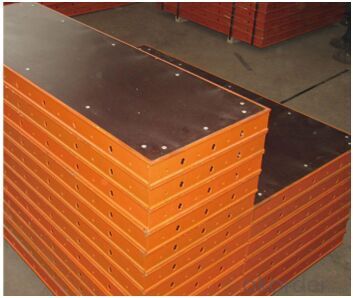

1. Structure of Light Steel Frame Formwork with plywood

Light steel frame formwork is constructed with two different plywood as frames-wood plywood and plastic plywood. The light frame formwork with plywood is quite weighing lightly and work faster.

2. Main Features of Structure of Light Steel Frame Formwork with plywood

Light with reasonably big sizes

Easily assemble with convenient use to reduce construction use and work load

Easy to get rid of concrete surface

More than 20 times repeated use

Warmth keeping for winter concrete use

Convenient for maintenance on site. One surface damaged , the other surface can be quickly replace.

Mainly used for vertical, horizontal and shear formwork in high building.

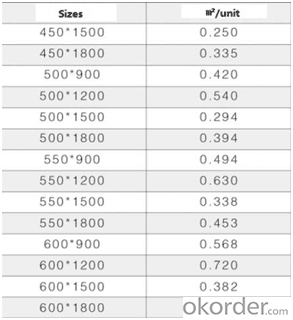

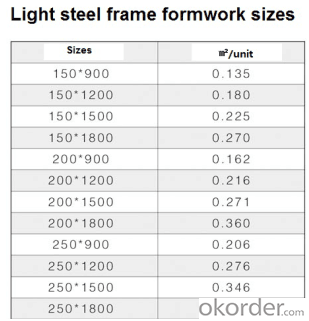

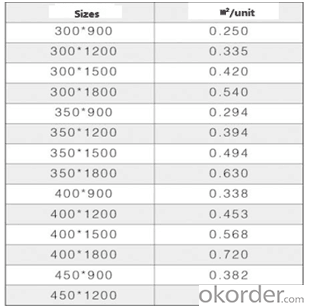

4. Light Steel Frame Formwork Specifications

5. FAQ of Light Steel Frame Formwork with plywood

1) What can we do for you?

.We can ensure the quality of the Light Steel Frame Formwork with Plywood and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Can steel frame formwork be used for both horizontal and vertical structures?

- Yes, steel frame formwork can be used for both horizontal and vertical structures. Its sturdy and durable construction enables it to support the weight and pressure of concrete for various types of structures, regardless of their orientation.

- Q: How does steel frame formwork contribute to the overall aesthetics of a structure?

- Steel frame formwork contributes to the overall aesthetics of a structure in several ways. Firstly, it allows for precise and accurate construction, ensuring that the structure is built according to the intended design. This results in clean lines, smooth surfaces, and consistent dimensions, which all contribute to a visually pleasing appearance. Additionally, steel frame formwork allows for flexibility in design. It can be easily customized and adapted to create various architectural shapes and forms, such as curves, angles, and intricate patterns. This versatility enables architects and designers to create unique and visually striking structures that stand out in their surroundings. Furthermore, steel frame formwork provides a high-quality finish to the concrete surfaces. The steel panels used in the formwork are usually smooth and durable, which ensures that the finished concrete will have a smooth and refined appearance. This is particularly important for structures where the exposed concrete is a prominent feature, such as in modern architectural designs. Moreover, steel frame formwork allows for efficient construction processes, which can contribute to the overall aesthetics of a structure. The use of steel formwork enables faster and more accurate construction, reducing the need for extensive on-site modifications and repairs. This results in a more streamlined construction process, minimizing disruptions and delays, and ultimately leading to a more visually appealing final outcome. In summary, steel frame formwork plays a significant role in enhancing the overall aesthetics of a structure. Its precision, flexibility in design, high-quality finish, and efficient construction processes all contribute to creating visually pleasing and architecturally impressive buildings.

- Q: How does steel frame formwork handle the placement of external cladding and façade materials within the concrete structure?

- Steel frame formwork offers a versatile and efficient system for constructing concrete structures, including the installation of external cladding and façade materials. This system has numerous advantages that simplify and manage the process effectively. To begin with, the steel frame formwork establishes a sturdy and stable framework for placing external cladding and façade materials. These steel frames are specifically designed to withstand the pressure exerted by the concrete during pouring, guaranteeing the structural integrity of the final product. With this stability, cladding and façade materials can be securely attached, ensuring proper alignment and fixation. Moreover, the steel frames can be easily adjusted and customized to accommodate various types and sizes of cladding and façade materials. This flexibility allows for precise material placement, ensuring a seamless and aesthetically pleasing finish. Additionally, the steel frames can be effortlessly dismantled and reassembled, providing convenient access to the structure for future maintenance or repairs. Another benefit of steel frame formwork is its ability to deliver a smooth and even surface for cladding and façade materials. The formwork system is designed to minimize imperfections or irregularities on the concrete surface, resulting in a consistent and level base for material installation. This quality finish enhances the overall appearance of the structure. Furthermore, steel frame formwork enables the integration of various construction techniques and materials, such as precast panels or curtain walls. This versatility allows for the incorporation of different architectural design elements and aesthetics into the concrete structure. The steel frames can be easily adapted to meet the specific requirements of cladding and façade materials, facilitating seamless integration with the overall design concept. In conclusion, steel frame formwork presents a reliable and efficient solution for handling the placement of external cladding and façade materials in concrete structures. Its strength, stability, flexibility, and ability to provide a smooth surface make it an ideal choice for ensuring proper installation and integration of these materials, resulting in a high-quality and visually appealing finished product.

- Q: ANSYS steel frame structure modeling, commonly used in size, density, Poisson's ratio is much better? Help。

- The Poisson's ratio of 0.3. is important for the tensile strength and yield strength, it is important to calculate these values, also want to see you taking material.

- Q: Are there any environmental considerations associated with steel frame formwork?

- Steel frame formwork is associated with several environmental considerations. Firstly, the production of steel requires a significant amount of energy and resources, contributing to carbon emissions and environmental degradation. This makes the process of producing steel frame formwork carbon-intensive. Furthermore, steel is a non-renewable resource that cannot be easily replenished once it is used. This raises concerns about the depletion of natural resources and the long-term sustainability of steel frame formwork. Additionally, steel is prone to corrosion when exposed to moisture or chemicals, leading to the need for replacements and repairs. Disposing of old or damaged steel formwork also presents environmental challenges, as it contributes to landfill waste. On a positive note, steel frame formwork can be reused multiple times, reducing its overall environmental impact. However, the transportation and handling of heavy steel frames can still result in additional carbon emissions. To address these environmental considerations, alternative materials such as recycled plastic, bamboo, or timber should be considered for formwork. These materials are renewable, have lower carbon footprints, and can be easily reused or recycled. Additionally, implementing sustainable practices in the construction industry, such as waste reduction, optimized design, and improved energy efficiency, can help minimize the environmental impact of steel frame formwork.

- Q: Can steel frame formwork be used for both smooth and textured column finishes?

- Yes, steel frame formwork can be used for both smooth and textured column finishes. Steel frame formwork provides a versatile and robust solution for constructing columns with various surface finishes. It allows for the creation of smooth column finishes by using appropriate form liners or by applying a smooth coating to the steel formwork. On the other hand, if a textured column finish is desired, the steel formwork can be modified or combined with textured form liners to achieve the desired result. This flexibility makes steel frame formwork a suitable choice for both smooth and textured column finishes, providing options for different architectural requirements or design preferences.

- Q: What are the safety precautions for transporting steel frame formwork?

- Some safety precautions for transporting steel frame formwork include securing the frames properly to prevent shifting or falling during transport, using appropriate lifting equipment and techniques to avoid injuries, ensuring that the load is within the weight capacity of the vehicle, and following all relevant transportation regulations and guidelines. It is also essential to inspect the formwork for any damages or defects before transportation to prevent accidents or structural failure.

- Q: What are the key considerations for selecting the appropriate steel frame formwork system for projects with unique architectural features?

- The key considerations for selecting the appropriate steel frame formwork system for projects with unique architectural features include the flexibility and adaptability of the system to accommodate the specific design requirements, the ability to handle complex geometries and irregular shapes, the level of customization and adjustability offered by the system, the ease of assembly and disassembly, the availability of necessary accessories and components, and the overall cost-effectiveness in terms of time, labor, and materials.

- Q: Can steel frame formwork be used in areas with high humidity levels?

- Yes, steel frame formwork can be used in areas with high humidity levels. Steel is known for its durability and resistance to corrosion, making it suitable for use in humid environments. However, proper maintenance and corrosion prevention measures should be taken to ensure the longevity and performance of the steel frame formwork.

- Q: How does steel frame formwork prevent concrete shrinkage or cracking?

- Steel frame formwork is an effective solution to prevent concrete shrinkage or cracking due to its robust and rigid structure. The steel frames act as a support system that holds the concrete in place during the curing process. This prevents the concrete from moving or shifting, allowing it to dry evenly and reducing the risk of shrinkage or cracking. One of the main advantages of using steel frame formwork is its ability to provide excellent reinforcement and stability to the concrete structure. The steel frames are designed with precise measurements and are securely fixed in place, ensuring that the concrete retains its shape and form while it cures. This eliminates any potential for uneven drying or settlement, which can lead to shrinkage or cracking. Additionally, steel is known for its high tensile strength and durability, making it an ideal material for formwork. The steel frames can withstand the pressure exerted by the wet concrete and prevent it from expanding or contracting excessively as it dries. This stability minimizes the development of internal stresses within the concrete, which are a common cause of shrinkage or cracking. Furthermore, steel frame formwork provides a smooth and seamless surface for the concrete. This prevents the formation of voids or air pockets, which can weaken the concrete structure and increase the likelihood of shrinkage or cracking. The tight fit between the steel frames ensures that the concrete is uniformly distributed and compacted, resulting in a stronger and more resilient finished product. Overall, steel frame formwork plays a crucial role in preventing concrete shrinkage or cracking by providing a stable and supportive structure during the curing process. Its robustness, precise measurements, and ability to withstand pressure ensure that the concrete retains its shape and dries evenly. By eliminating uneven drying, settlement, and internal stresses, steel frame formwork helps to create a high-quality, durable, and crack-free concrete structure.

Send your message to us

Light Steel Frame Formwork with Plywood for Two Level Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 70000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords