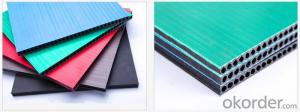

Light Weight Plastic Formworks for Construction Projects

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

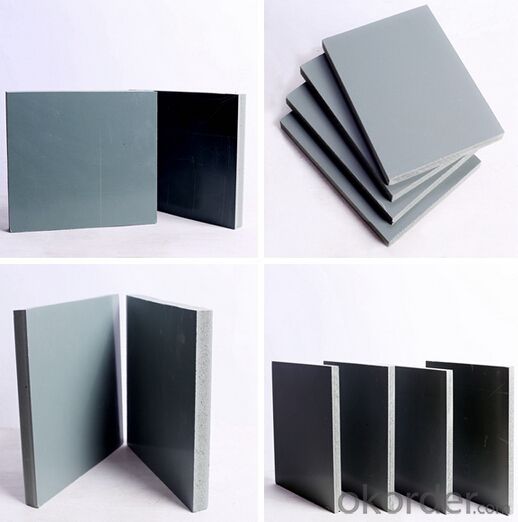

Waterproof Plastic PVC Foam Board Formworks Introduction

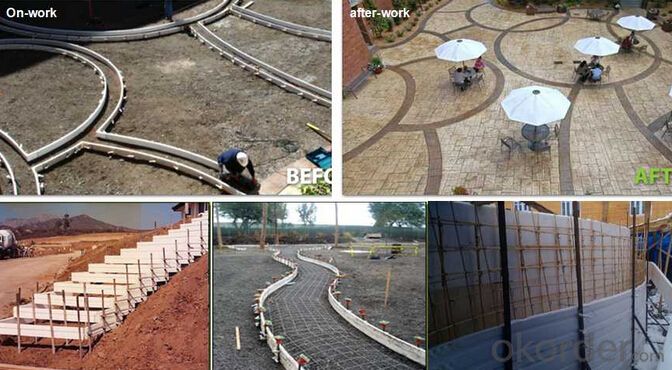

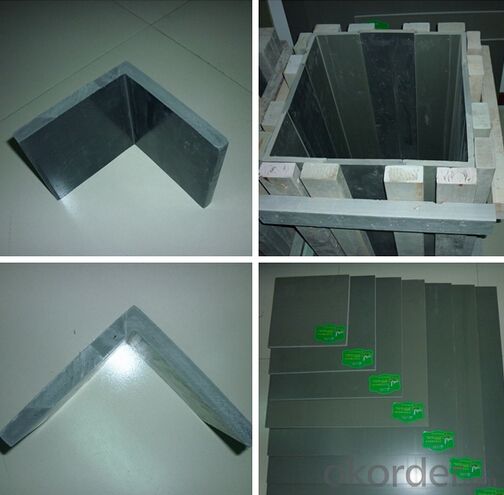

This kind of construction formwork can be special form like column and square.

They can be used in bridge, office building and roads construction.

Our products have characters such as energy conservation, environment-protection, and in low price. Another, turnovers can be up to 30 times, temperature adaptation range is wide. Plastic steel template can be any sizes so that it has wide adaptation.

easy installed and removed, sawed and drilled, and accessories complete.

save working hours more than 30% and increase efficiency more than 40%.

save construction template allocable cost over than 50%

Waterproof Plastic PVC Foam Board Formworks Feature

1. Life:turnover can be up to 40times

2. Tempreture condition:-20°C to 60°C

3. Feature:save 40%manhours and 50 %allocable cost

4. Convenient installation:be widely accepted by workers

5. Moldable size:size can be changed freely.

6. Resist compression:can support more than 5000 kilograms

7. Waterproof:100%

8. Useable widely used in building and construction

9. Energy saving,/environmental protection,/resource circulation

Waterproof Plastic PVC Foam Board Formworks Paramwter

Material: PVC | Structure: solid plate |

Cycle-index: 30 times above | Water content :0.3% |

Water thickness expansion rate: 0.1% | Static bending strength:21.9MPa |

Bending elastic modulus:1280MPa | Wear resistant surface(g/100r):0.08g/100r |

Condition after heating: no bubbles, no crack, no pitting | After heating the size change rate :0.20% |

Grip screws to board : 1470N | Grip screws to the edge of the board : 1070N |

Anti impact performance :14.1mm Impact toughness :64.8KJ/ m2 | High temperature repeated dimension change rate :0.12% |

Waterproof Plastic PVC Foam Board Formworks Specification

1, 15*915*1830(mm) 16.5Kg/pc±1Kg

2, 15*1220*1240(mm) 29Kg/pc±1Kg

3, Specifications can be customized

4, About 100M3 /T

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- Pvc plate deformation are: physical deformation and chemical deformation.A physical deformation, the cause:???? High temperature lead to deformation, if it is such a deformation, targeted plastic raw materials for high temperature modification, can effectively improve such problems???? Improper textile lead to deformation, such deformation has two reasons, a plate of raw materials can not meet the actual requirements of the product requirements, re-deployment of raw materials formula to meet the actual requirements of the product can be. Second, the processing and storage methods are not correct, leading to deformation, such problems can solve the problem from the rootTwo chemical deformation: mainly the molecular structure of raw materials change.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- This is mainly to see how the use of workers in the process of operation by standard, 50 times is entirely possible. The use of plastic templates a little bit, the most important thing is to focus on cost savings, integrated plastic template cost is the lowest. But the price is more expensive than the wood template, long-term, large-scale use is cost-effective.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- Is the template based on your product requirements, can you talk about the requirements of each part of your product?

- Q: Who used it, how not universal.

- The product has the following characteristics: 1. General product specifications 3020 * 1220 * (12-20) mm. Product area, construction joints less, improve the construction speed and efficiency. 2. The product can be sawed, planing, can be nailed, can be repaired, processing is very convenient. 3. Strong plastic PP plastic template does not absorb water, there is no stratification, cracking phenomenon.

- Q: Europe and the United States national construction template is made of plastic or wood

- Part of the place with stones, as the case may be, but certainly yes, Europe and the United States have anti-seismic buildings

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- The main advantages are:1, the surface smooth and smooth, high strength, the provincial workers, the expected material, can meet the requirements of clear water concrete template, after stripping without cleaning the surface of the template, thus saving a lot of labor, template flatness can be controlled within 0.3mm, thickness uniformity, Can be controlled within ± 0.3mm, wood than the wood to save 2/3 of the nails.2, good water resistance, toughness, long-term immersion is not layered, water swelling rate of less than 0.06%, in -30 ℃ _ +60 ℃ range of normal use, the use of 6 years of aging of 15%, normal use of 8 Years or more.3, plasticity, according to the design and component size requirements, processing and production of different shapes and different specifications of the template, a curvature of the template for the production of a more simple template can be drilling nails, saws, planing and other wood mold with the same machinability , On-site stitching simple and convenient.4, recyclable use, plastic template to a certain extent can be fully recycled, regardless of the size of the old and new, after processing, can be added to produce a new template

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- Are generally wood board, plastic with less

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- This size is an international common size. Because more foreign use of foot units, 1 foot = 30.5cm, 1830 × 915 is usually said that the three or six feet board.

- Q: The price of raw materials can say better, is the PVC material.

- Templates in accordance with the different prices of materials are also very different. The general plywood is 50-65 / sheet.

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Over the past two years the domestic market has appeared several "plastic building template", many builders are also trying to use plastic building templates, we all recognize that plastic building template is to replace steel mold, wood mold, bamboo mold of the inevitable product, Is the future direction of the development of architectural templates. Now the country has six or seven plastic building template manufacturers. Production of plastic building templates are different materials, in order to help all the correct selection of builders, the market is now on the composition of several plastic building templates and performance for a rough analysis, to all the use of plastic building templates to build a wake up , To avoid blind selection and cause unnecessary losses.

Send your message to us

Light Weight Plastic Formworks for Construction Projects

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords