New Technology Plastic Formwork for Hotel Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Waterproof Plastic PVC Foam Board Formworks Introduction

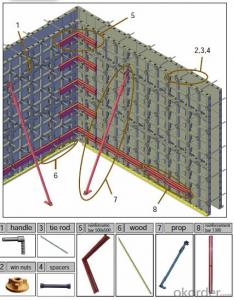

This kind of construction formwork can be special form like column and square.

They can be used in bridge, office building and roads construction.

Our products have characters such as energy conservation, environment-protection, and in low price. Another, turnovers can be up to 30 times, temperature adaptation range is wide. Plastic steel template can be any sizes so that it has wide adaptation.

easy installed and removed, sawed and drilled, and accessories complete.

save working hours more than 30% and increase efficiency more than 40%.

save construction template allocable cost over than 50%

Waterproof Plastic PVC Foam Board Formworks Feature

1. Life:turnover can be up to 40times

2. Tempreture condition:-20°C to 60°C

3. Feature:save 40%manhours and 50 %allocable cost

4. Convenient installation:be widely accepted by workers

5. Moldable size:size can be changed freely.

6. Resist compression:can support more than 5000 kilograms

7. Waterproof:100%

8. Useable widely used in building and construction

9. Energy saving,/environmental protection,/resource circulation

Waterproof Plastic PVC Foam Board Formworks Paramwter

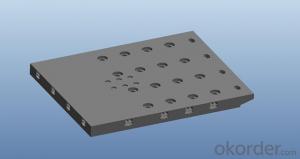

Material: PVC | Structure: solid plate |

Cycle-index: 30 times above | Water content :0.3% |

Water thickness expansion rate: 0.1% | Static bending strength:21.9MPa |

Bending elastic modulus:1280MPa | Wear resistant surface(g/100r):0.08g/100r |

Condition after heating: no bubbles, no crack, no pitting | After heating the size change rate :0.20% |

Grip screws to board : 1470N | Grip screws to the edge of the board : 1070N |

Anti impact performance :14.1mm Impact toughness :64.8KJ/ m2 | High temperature repeated dimension change rate :0.12% |

Waterproof Plastic PVC Foam Board Formworks Specification

1, 15*915*1830(mm) 16.5Kg/pc±1Kg

2, 15*1220*1240(mm) 29Kg/pc±1Kg

3, Specifications can be customized

4, About 100M3 /T

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- The lower the density of the foam board is easier to deform.Crust foam can be changed to coextrusion foam. General cross-linking or blending halogenation and other methods to improve Vicat. Reduce traction override

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- This is not know your product materials and performance requirements, but the mold, then we generally use 45 steel, if the product is not corrosive strong, then what can be used to compare 50 steel.

- Q: I heard that there are building aluminum template and plastic template it? Which is better?

- Aluminum alloy template construction is convenient, high efficiency: aluminum alloy building template system assembly is simple, convenient, average weight 30KG / m2, completely assembled by the artificial, do not need any mechanical equipment assistance (workers usually only need a wrench or a small hammer Easy to install), skilled installation workers can install 20-30 square meters per person per day (compared with the wooden mold: aluminum mold workers only need to install wood workers 70-80%, and do not need skilled workers, just install Before the construction of the staff can be a simple training can be).

- Q: Europe and the United States national construction template is made of plastic or wood

- With plastic construction, then, is the most solid touch on the back, Europe and the United States part of the country after the earthquake so the use of wood plus wire

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- We use the pp building template. The effect is also good, top about. They also recycle the plastic building template we used for 3 tons for 1 ton.

- Q: Types of building templates? What is the water template?

- Building a template, the use of rear surface roughness is better, do not need to deal with the second. Provincial workers, time-saving.

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- The general building materials market have to sell, I hope my answer can help you ~

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- Are generally wood board, plastic with less

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- You can do that kind of ah! Raw materials are not easy to find

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Over the past two years the domestic market has appeared several "plastic building template", many builders are also trying to use plastic building templates, we all recognize that plastic building template is to replace steel mold, wood mold, bamboo mold of the inevitable product, Is the future direction of the development of architectural templates. Now the country has six or seven plastic building template manufacturers. Production of plastic building templates are different materials, in order to help all the correct selection of builders, the market is now on the composition of several plastic building templates and performance for a rough analysis, to all the use of plastic building templates to build a wake up , To avoid blind selection and cause unnecessary losses.

Send your message to us

New Technology Plastic Formwork for Hotel Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords