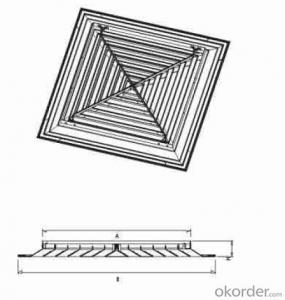

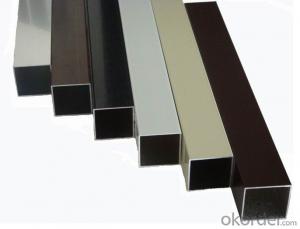

aluminium square tube

aluminium square tube Related Searches

Aluminium Square Tube Aluminum Square Tube Stock Square Stock Aluminum Tubing Alumina Tube Aluminium Tape Square Stock Aluminum Tape Aluminium Aluminum Extruded Tubing Aluminum Tape Stock Aluminum Tube Sizes Aluminum Sheet Circle Large Diameter Aluminum Tube Aluminium Circle Aluminum Tube Stock Sizes Transparent Rubber Tube Aluminum Circle Sheet 1 Inch Aluminum Square Stock Aluminum Square Stock For Sale Aluminum Rectangular Tube Stock Aluminium Extrusion Aluminum Tray Circle Aluminium Curtain Wall Tube Aluminum Stock 2 Aluminum Square Stock Aluminum Circle Aluminum Sealing Tape Aluminum Extrusion Shapes Aluminum Strip Conductive Aluminum Tape Cooking Aluminium Circlealuminium square tube Supplier & Manufacturer from China

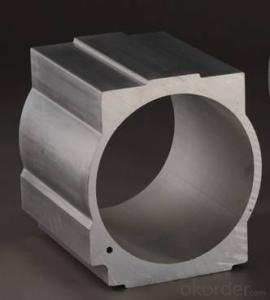

Aluminium square tube is a versatile product that is widely used in various industries due to its lightweight, corrosion resistance, and high strength. This type of tubing is commonly employed in construction, automotive, and aerospace applications, as well as in the manufacturing of furniture, ladders, and other structural components. The product's unique properties make it an ideal choice for applications where durability and low weight are essential.Aluminium square tube is utilized in a broad range of scenarios, from architectural projects that require load-bearing structures to intricate designs in the automotive industry that demand precision and stability. Its ability to maintain its shape and resist corrosion makes it a popular choice for outdoor applications, such as in the construction of pergolas, balconies, and other outdoor structures. Additionally, its lightweight nature makes it suitable for use in transportation, where reducing weight is crucial for fuel efficiency and performance.

Okorder.com is a leading wholesale supplier of aluminium square tube, offering a vast inventory of this product to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the aluminium square tube they provide meets the highest standards of performance and reliability. Their extensive inventory allows customers to find the exact specifications and quantities they require, making them a trusted source for businesses and individuals alike.

Hot Products