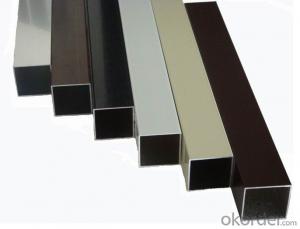

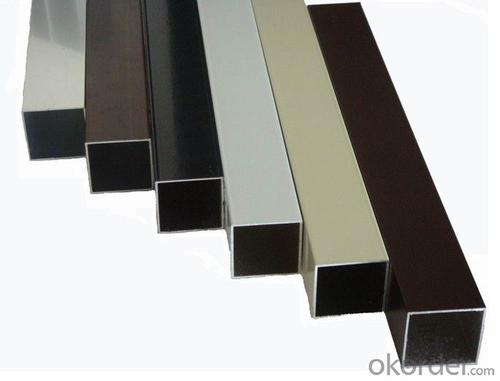

Mk Aluminum Profiles - Aluminium Square Tube Profile for Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Aluminum Square Tubes

1: Extrusion tooling free!

2: Fast lead time!

3: Guaranteed quality!

Aluminum Square Tubes

Dongke Aluminum has many existing toolings, please do not hesitate to contact us. Our professional and very amenable Dongkers are at your service!

1-Chemical Composition Of Aluminum Alloy

| Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | 0.45-0.9 | <0.35 | < 0.1 | < 0.1 | < 0.1 | < 0.1 | < 0.1 | < 0.05 | < 0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.8-1.2 | <0.7 | 0.15-0.4 | < 0.15 | < 0.25 | 0.04-0.35 | < 0.15 | < 0.05 | < 0.15 | Surplus |

2- Chemical Properties Of Aluminum Alloy

| Alloy | Temper | Thickness | Intensity streching resistance 6b (Mpa) | Intensity of bending 6p0.2(Mpa) | Stretching rate | T of tested samples (mm) | HV | HW |

| ≥ | ||||||||

| 6063 | T5 | All | 160 | 110 | 8 | 0.8 | 58 | 8 |

| 6061 | T6 | All | 205 | 180 | 8 | 0.8 | 90 | 15 |

- Q: Can aluminum profiles be extruded into hollow profiles?

- Yes, there are two ways to squeeze hollow profiles:1, in the die area, the use of shunt mold2, in the extruder processing, the use of punch pin, in general, this is for the double action extruder, used for extrusion seamless pipe. The reverse press also works.

- Q: Are aluminum profiles suitable for swimming pool enclosures?

- Swimming pool enclosures benefit greatly from the use of aluminum profiles. This material is not only durable and lightweight, but it also has a high resistance to rust and corrosion, making it perfect for humid and moist environments like swimming pools. Moreover, aluminum profiles can be easily customized to fit any pool size or shape, offering great versatility. In addition to this, they provide exceptional structural strength, ensuring the stability and longevity of the enclosure. Another advantage of using aluminum profiles is that they require minimal maintenance, resulting in cost-effectiveness. All in all, aluminum profiles are an excellent choice for protecting and enhancing the swimming pool area due to their durability, versatility, and low maintenance.

- Q: What specific coatings or finishes are necessary for aluminum profiles to withstand cold weather conditions?

- <p>In cold climates, aluminum profiles may require special coatings or finishes to enhance durability and resistance to corrosion. These can include anodizing, which forms a protective oxide layer on the aluminum surface, or powder coating, which provides a hard, durable finish. Additionally, thermal breaks may be incorporated into the design to reduce heat transfer and prevent condensation. It's crucial to select the right finish based on the specific environmental conditions and the intended use of the aluminum profile.</p>

- Q: Surface treatment method of aluminium profile

- With a little bit of gauze, destroy the surface of the oxide layer, destroy (also white bar destroyed) in cloth with anhydrous alcohol, rub on coated white petrolatum, anti oxidation

- Q: Are aluminum profiles suitable for outdoor furniture and fences?

- <p>Yes, aluminum profiles are commonly used for outdoor furniture and fences due to their durability, resistance to corrosion, and low maintenance requirements. Aluminum doesn't rust like iron or steel, making it ideal for outdoor applications where exposure to weather elements is constant. It also retains its structural integrity over time and can be easily powder-coated or anodized for added protection and aesthetic appeal.</p>

- Q: What are the strategies to reduce the environmental footprint when utilizing aluminum profiles in construction projects?

- <p>To minimize the environmental impact of using aluminum profiles in construction, consider the following strategies: Use recycled aluminum whenever possible, as it requires significantly less energy to produce than new aluminum. Opt for energy-efficient manufacturing processes and choose suppliers with strong environmental credentials. Design for disassembly and recycling to facilitate the reuse of aluminum profiles at the end of their life. Implement sustainable construction practices that reduce waste and emissions. Finally, educate stakeholders about the importance of sustainable materials and encourage the adoption of eco-friendly practices throughout the construction process.</p>

- Q: Which aluminum profile is better here in Guangdong?

- 1 、 aluminum material2, Zhong Wang aluminum3 Asia Aluminum4, Hing Fat aluminum5, the phoenix aluminum aluminum6, the United States and aluminum7, vibration or aluminum8 、 Nanshan aluminum material9, pillars of aluminum10, South South aluminum

- Q: What are the top 20 Chinese architectural aluminum profiles?

- 14, Fujian public security Aluminum Co. Ltd.15, Zhejiang pillars of new material Limited by Share Ltd16, Lear aluminum industry Limited by Share Ltd17 、 Ming emperor Aluminum Industry Co., Ltd.18, Guangdong silver100 innovation Aluminum Co. Ltd.19 、 Qingyuan Asia Aluminum Co., Ltd.20 、 Guanghan Sichuan Sanxing Aluminium Industry Co., Ltd.

- Q: What are the potential hazards or risks associated with the use of aluminum profiles in construction projects?

- <p>Safety concerns related to using aluminum profiles in construction include potential corrosion due to exposure to harsh weather conditions, risk of electrical conductivity which may lead to electrocution hazards, and the possibility of thermal expansion and contraction causing structural instability. Additionally, improper installation can lead to structural failure, and the lightweight nature of aluminum may not provide sufficient strength in load-bearing applications. It's crucial to ensure proper design, quality materials, and adherence to safety standards to mitigate these risks.</p>

- Q: This question asks about the various materials used to coat aluminum profiles for improving their appearance.

- <p>There are several types of coating materials used on aluminum profiles for aesthetic purposes, including: 1. Powder coating, which offers a durable and colorful finish. 2. Anodizing, a process that enhances the surface hardness and provides a decorative effect. 3. Electrophoretic coating, known for its smooth and even finish. 4. PVDF (Polyvinylidene Fluoride) coating, which is weather-resistant and offers a wide color palette. 5. Thermal spraying, which can provide a decorative or protective layer. 6. Sol-gel coating, a newer technology that offers excellent adhesion and corrosion resistance. These coatings not only enhance the visual appeal but also protect the aluminum from environmental factors and wear.</p>

Send your message to us

Mk Aluminum Profiles - Aluminium Square Tube Profile for Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords