Aluminium Square Tube

Aluminium Square Tube Related Searches

aluminium square tube Aluminum Square Tube Stock Square Stock Aluminum Tubing Alumina Tube Aluminium Tape Tape Aluminium Square Stock Aluminum Aluminium Circle Aluminum Extruded Tubing Tube Aluminum Stock Aluminum Tape Aluminum Square Stock For Sale Large Diameter Aluminum Tube Transparent Rubber Tube Stock Aluminum Tube Sizes 2 Aluminum Square Stock 1 Inch Aluminum Square Stock Aluminum Rectangular Tube Stock Iron Tube Aluminum Tube Stock Sizes Aluminum Strip Aluminum Circle Aluminum Tray Circle Anodized Aluminum Tube Stock Iron Tubes Aluminium Extrusion Aluminium Curtain Wall Air Intake Tubes 3 4 Aluminum Square Stock Cooking Aluminium CircleAluminium Square Tube Supplier & Manufacturer from China

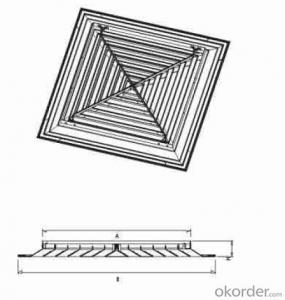

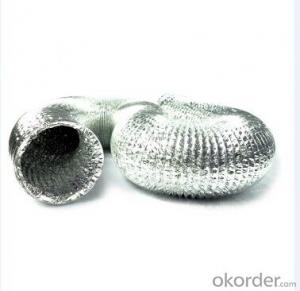

Aluminium Square Tube is a type of metal product known for its lightweight, corrosion resistance, and high strength. This product is made from high-quality aluminum alloys and is extensively used in various industries due to its versatility and durability. It is commonly utilized in construction, automotive, aerospace, and electrical applications, where its strength-to-weight ratio and resistance to harsh environments make it an ideal choice. The usage scenarios for Aluminium Square Tube are vast, ranging from structural framing and window frames to automotive components and electrical conduits. Its ability to maintain its properties under various conditions, such as extreme temperatures and exposure to moisture, further enhances its appeal in these applications.Okorder.com is a reputable wholesale supplier of Aluminium Square Tube, offering a vast inventory to cater to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Aluminium Square Tube they provide meets the highest industry standards. Their extensive inventory allows them to serve a wide range of industries, providing the necessary materials for various projects and applications. By partnering with Okorder.com, customers can expect to receive top-quality Aluminium Square Tube at competitive prices, backed by exceptional service and support.

Hot Products