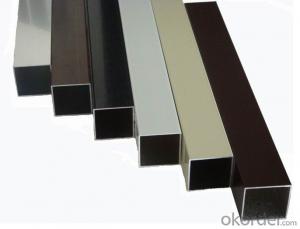

Anodized Aluminum Square Tubes for Doors and Windows Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

anodized aluminum square tube

1.Alloy 2014 2024 7020 6061 7075

2.Temper:F O T4 T5 ,T6

3.Out diameter:4.5-610 mm

Product name | anodized aluminum square tube | |

Shape | Round, oval, square, rectangle | |

Size | Out Diameter | 4.5-610 mm |

Wall Thickness | 1-110 mm | |

Length | According to customer’s requirement | |

Alloy | 1070-1100 3003 5052 5754 5083 5056 2017 2014 2A12 2024 6060 6082 6061 6063 7050 7075 7005 7020 7A09 | |

Temper | F, O, T4, T5, T6 | |

Standard | GB /ASTM | |

Surface Treatment | 1.mill finished 2.anodizing:shiny anodized,frosty anodized 3.electrophoretic coating:shiny elecyrophoretic,frosty electrophoretic 4.electrophoretic color powder coating:normal color,special color. 5.fluorocarbon powder spraying:normal color,special paper 6.polished 7.wood grain coating: special paper, special paper

| |

Application | Construction, decoration and industry | |

Origin | Chongqing ,China | |

Port | Chongqing or Shanghai | |

MOQ | 2 Metric Tons | |

Delivery Time | 30 work days after deposit or L/C | |

Payment Terms | T/T, irrevocable L/C at sight. | |

Supply Ability | 5000 Metric Ton / Month | |

Packaging | Foam paper and carton box package,kraft paper package,plastic film and the plastic wrap package are optional,or as requested. | |

- Q: How do you prevent galvanic corrosion when combining aluminum profiles with concrete or masonry?

- One effective method to prevent galvanic corrosion when combining aluminum profiles with concrete or masonry is to use a protective barrier. Applying a suitable coating or corrosion-resistant material on the aluminum surface can create a barrier between the aluminum and the concrete/masonry, preventing direct contact and minimizing the risk of galvanic corrosion. Additionally, using isolation materials such as gaskets or non-conductive joint fillers between the aluminum profiles and the concrete/masonry can further help to prevent galvanic corrosion by isolating the dissimilar metals. Regular inspection and maintenance are also essential to identify any potential corrosion issues early on and take necessary preventive measures.

- Q: This question asks for a list of various types of coatings applied to aluminum profiles to prevent corrosion.

- <p>Aluminum profiles are protected from corrosion through several types of coatings. These include: Anodizing, which forms a protective oxide layer; Powder Coating, a durable and weather-resistant finish; Electrophoretic Deposition (E-coat), offering a smooth, corrosion-resistant surface; Fluoropolymer coatings, known for their exceptional chemical resistance and UV stability; and Thermal Spray Coatings, which provide a hard, wear-resistant surface. Each method serves to enhance the aluminum's resistance to environmental factors and extend its lifespan.</p>

- Q: This question asks for an explanation of various methods used to manufacture aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, but also including casting, rolling, and machining. Extrusion is the most common method, where aluminum is heated and forced through a die to create a desired shape. Casting involves pouring molten aluminum into molds to form specific profiles. Rolling is used to produce flat sheets or plates, which can then be further processed. Machining involves cutting and shaping aluminum using tools like lathes and mills. Other processes include forging, which deforms aluminum under high pressure, and powder metallurgy, where aluminum powder is compacted and sintered into a solid profile. Each process has its advantages and is chosen based on the desired profile shape, strength, and application.</p>

- Q: This question asks for criteria or methods to determine if a specific aluminum profile is appropriate for a given project.

- <p>To determine if an aluminum profile is suitable for your project, consider the following factors: 1) Load-bearing capacity - Check if the profile can withstand the weight and stress it will be subjected to. 2) Dimensional requirements - Ensure the profile's size and shape match your project's specifications. 3) Corrosion resistance - Verify if the profile is resistant to the environmental conditions it will be exposed to. 4) Surface finish - Confirm if the profile's finish meets your aesthetic and functional needs. 5) Compatibility with other materials - Make sure the profile can be effectively joined or integrated with other materials in your project. Consult with an engineer or the profile manufacturer for specific recommendations based on your project's unique requirements.</p>

- Q: Are aluminum profiles suitable for awnings and canopies?

- Yes, aluminum profiles are suitable for awnings and canopies. Aluminum is a lightweight and durable material that can withstand various weather conditions. It is resistant to corrosion, making it ideal for outdoor applications. Additionally, aluminum profiles can be easily customized and are available in different designs, making them a popular choice for awnings and canopies.

- Q: What are the cost considerations for using aluminum profiles?

- Some cost considerations for using aluminum profiles include the initial cost of purchasing the profiles themselves, any additional costs for custom or specialized profiles, the cost of installation and assembly, maintenance costs, and potential future costs for repairs or replacements. Additionally, the cost of aluminum profiles may vary depending on the quality and thickness of the material used.

- Q: This question asks for a comparison between aluminum profiles and other building materials regarding their cost and performance.

- <p>Aluminum profiles are often more cost-effective than materials like steel or wood in the long run due to their durability and low maintenance requirements. They offer high strength-to-weight ratios, making them ideal for structures where weight is a concern. Additionally, aluminum profiles have excellent resistance to corrosion and weathering, which reduces the need for repainting or replacement over time. They are also energy-efficient, as they can help in reducing heat transfer, thus lowering energy costs for heating and cooling. However, the initial cost of aluminum profiles can be higher than some alternatives, but their long-term performance and low maintenance can offset this initial expense.</p>

- Q: Explain if aluminum profiles can be utilized in constructing energy-efficient building systems and if so, how they contribute to energy efficiency.

- <p>Yes, aluminum profiles can be used to create energy-efficient building systems. They are lightweight yet strong, which reduces the energy required for construction. Aluminum profiles also have excellent thermal conductivity, allowing them to be used in double-glazed windows and doors, improving insulation and reducing heat loss. Additionally, aluminum can be easily recycled, reducing the energy needed for new materials. Their high reflectivity can also help in reducing heat absorption, further contributing to energy efficiency.</p>

- Q: What are the environmental effects of utilizing aluminum profiles in the construction industry?

- <p>Yes, there are environmental impacts associated with using aluminum profiles in construction. Aluminum production is energy-intensive, which contributes to greenhouse gas emissions. However, aluminum is recyclable, and its recycling process requires significantly less energy than primary production, reducing environmental impact. Additionally, aluminum profiles are lightweight, which can reduce transportation emissions. Despite these benefits, concerns remain about the energy used in aluminum production and the potential for leaching of aluminum into the environment, which can affect soil and water quality.</p>

- Q: What are the various standards and regulations governing the use of aluminum profiles in construction?

- <p>Aluminum profiles in construction are governed by a variety of standards and regulations that ensure their quality, safety, and performance. These include ISO standards such as ISO 7039 for anodized aluminum and ISO 9001 for quality management systems. National standards like ASTM B221 in the USA and EN 755 in Europe specify mechanical properties and chemical composition. Building codes such as the International Building Code (IBC) and Eurocode 9 also provide guidelines for the use of aluminum in construction. Additionally, there are specific regulations for fire resistance, sustainability, and environmental impact, like the European CE marking for construction products. Compliance with these standards is crucial for manufacturers and builders to ensure the reliability and safety of aluminum profiles used in construction projects.</p>

Send your message to us

Anodized Aluminum Square Tubes for Doors and Windows Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords