LED Aluminum Profiles for Coated Aluminum Round Tubes in Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

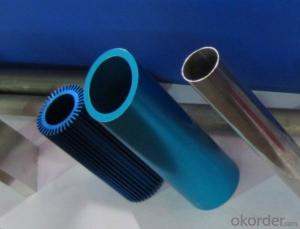

Name:aluminum tube&aluminum pipe

Material | 1000series,2000series,3000series.... |

Temper | T4,T5,T6 |

ISO Certificate | ISO9001:2008,SGS |

Size | The size are available in accordance with customers' options. |

Mill finish, Powder Coating, Anodizing, Sandblasting Anodizing, | |

Surface Processing | Cataphoresis, Sandblasting Cataphoresis, Wooden Print etc. |

Shape | round pipe |

Use | Building,Machine,Decoration,etc |

Color | Silver,Golden,Black,Red,Blue a,etc |

Packing: | Export sea worthy package |

Delivery: | Within 30 days after receiving 30%T/T of deposit or L/C |

MOQ: | 1 Metric Ton/Metric Tons |

Price terms: | FOB, CFR, CIF |

Payment terms: | T/T, L/C |

Application | aluminum pipe applies to Structural use ,roofing, commercial use, household appliance, industry, family etc |

Quality control: | a)Mill Test Certificate is supplied with shipment. b)Third party inspection is highly welcomed. |

- Q: Can aluminum profiles be used in the construction of amusement park rides?

- Yes, aluminum profiles can be used in the construction of amusement park rides. Aluminum is a popular choice for constructing various components of amusement park rides due to its lightweight and durable properties. The profiles can be easily shaped and welded to create complex structures, such as roller coaster tracks, supports, and frames for other rides. Aluminum's corrosion resistance also makes it suitable for outdoor environments where the rides are exposed to weather conditions. Additionally, aluminum is a sustainable material as it can be recycled, making it an environmentally friendly choice for amusement park ride construction. Overall, aluminum profiles provide a versatile and reliable option for creating safe and exciting amusement park rides.

- Q: How do you install aluminum profiles?

- To install aluminum profiles, first, determine the appropriate location and measurements for the profiles. Then, using a saw or cutter, cut the profiles to the desired length. Next, attach the profiles to the designated area using screws or brackets. Ensure that the profiles are securely fastened. Finally, make any necessary adjustments or modifications to achieve the desired fit and appearance.

- Q: This question asks whether aluminum profiles can be utilized as a material for exterior wall insulation panels.

- <p>Yes, aluminum profiles can be used for exterior wall insulation panels. They are commonly used due to their durability, corrosion resistance, and lightweight properties. Aluminum profiles provide structural support and can be combined with insulation materials such as polyurethane or mineral wool to create efficient thermal insulation. They are also compatible with various cladding systems, making them a versatile choice for exterior wall insulation.</p>

- Q: This question asks for an overview of the various types of adhesives that are compatible with aluminum profiles.

- <p>Aluminum profiles can be bonded with several types of adhesives, each offering unique properties for different applications. Epoxy adhesives are strong and durable, suitable for high-strength bonding. Cyanoacrylate (super glue) offers fast bonding with good strength and is easy to use. Silicone adhesives are flexible and weather-resistant, making them ideal for outdoor applications. Polyurethane adhesives provide strong bonds with excellent flexibility and are resistant to moisture and chemicals. Acrylic adhesives are known for their versatility and strong bonds, while anaerobic adhesives cure in the absence of air and are often used for threaded fasteners. Each adhesive type has specific curing times and temperature resistance, so the choice depends on the specific requirements of the project.</p>

- Q: What are the advantages of utilizing aluminum profiles in construction projects in terms of environmental impact?

- <p>Aluminum profiles in construction offer several environmental benefits. They are highly recyclable, which reduces waste and conserves natural resources. Aluminum is lightweight, reducing transportation emissions. It also has a high strength-to-weight ratio, allowing for more efficient use of materials. Additionally, aluminum has excellent thermal conductivity, which can contribute to energy efficiency in buildings. Furthermore, aluminum production technology has advanced to reduce energy consumption and emissions during the manufacturing process. Overall, the use of aluminum profiles can lead to more sustainable and environmentally friendly construction practices.</p>

- Q: This question asks for methods to prevent aluminum profiles from rusting during the transportation process.

- <p>To prevent rusting of aluminum profiles during transportation, ensure proper packaging with moisture-resistant materials. Use protective films or covers to shield the profiles from direct contact with moisture and humidity. Maintain a controlled environment in the transport vehicle, avoiding high humidity and condensation. Regularly inspect the profiles for any signs of moisture or damage and address them promptly. Additionally, consider using rust inhibitors or anti-corrosion coatings on the aluminum profiles before packaging. Always handle the profiles with care to avoid scratches or damage that could lead to rusting.</p>

- Q: Are aluminum profiles suitable for decorative applications?

- Yes, aluminum profiles are suitable for decorative applications. Aluminum is a versatile material that offers several advantages in decorative applications. Firstly, aluminum profiles can be easily shaped and formed into various designs, allowing for endless possibilities in decorative applications. They can be extruded into different shapes, sizes, and patterns, giving designers the freedom to create unique and aesthetically pleasing decorative elements. Moreover, aluminum profiles offer excellent durability and corrosion resistance, making them suitable for both indoor and outdoor decorative applications. Aluminum is known for its ability to resist rust and weathering, ensuring that decorative elements made from aluminum profiles will maintain their appearance for a long time. Additionally, aluminum profiles can be finished in various ways to enhance their decorative appeal. They can be anodized or powder-coated to add color, texture, and protection to the surface. These finishing options allow for customization and the ability to match the profiles with the overall design scheme. Furthermore, aluminum profiles are lightweight yet strong, making them easy to install and handle during the decorative application process. This characteristic also makes them suitable for applications where weight is a consideration, such as in suspended or wall-mounted decorative elements. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, and the production process of aluminum profiles requires considerably less energy compared to other materials. Choosing aluminum profiles for decorative applications aligns with sustainable design principles and contributes to reducing the environmental impact. In conclusion, aluminum profiles are highly suitable for decorative applications due to their versatility, durability, corrosion resistance, customization options, lightweight nature, and sustainability. Whether it's for interior or exterior decorative elements, aluminum profiles offer a wide range of possibilities to enhance the aesthetic appeal of any space.

- Q: Can aluminum profiles be used in agricultural machinery manufacturing?

- Yes, aluminum profiles can be used in agricultural machinery manufacturing. Aluminum is a lightweight and versatile material that offers various benefits for agricultural machinery. It is corrosion-resistant, which is essential for equipment exposed to harsh weather conditions and chemicals used in farming. Additionally, aluminum profiles provide excellent strength-to-weight ratio, allowing for the construction of sturdy and durable machinery without adding unnecessary weight. Aluminum's high thermal conductivity also enables efficient heat dissipation, preventing overheating of machinery components. Moreover, aluminum profiles can be easily formed, machined, and welded, providing flexibility in design and manufacturing processes. Overall, the use of aluminum profiles in agricultural machinery manufacturing can result in improved performance, fuel efficiency, and reduced maintenance costs.

- Q: What specific criteria or standards must be met when utilizing aluminum profiles in the construction of environmentally friendly buildings?

- <p>In green building construction, aluminum profiles must meet certain sustainability and environmental requirements. These include high recyclability to reduce waste, low embodied energy to minimize environmental impact during production, and adherence to standards like LEED certification. Profiles should also be durable and low-maintenance to reduce the need for replacement and associated waste. Additionally, the use of eco-friendly coatings and finishes that do not release harmful substances is crucial. Compliance with regional green building codes and regulations is also mandatory.</p>

- Q: Are aluminum profiles resistant to termites and insects?

- Yes, aluminum profiles are highly resistant to termites and insects. Unlike wood, which is susceptible to termite infestations and insect damage, aluminum is a nonporous material that does not provide a food source for these pests. Additionally, aluminum profiles are typically coated with protective finishes, such as powder coating or anodizing, which further enhance their resistance to termites and insects. This makes aluminum profiles a durable and long-lasting option for various applications, such as window frames, door frames, and other construction projects where termite or insect damage is a concern.

Send your message to us

LED Aluminum Profiles for Coated Aluminum Round Tubes in Furniture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords