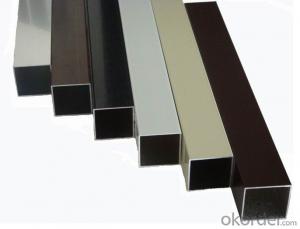

LED Aluminum Profiles for Furniture - Aluminium Rectangular Tubes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

aluminium profile tube for construction

1.Square tube aluminium extrusion for door and window

2.aluminum window frame extrusion

3.aluminum extrusion profiles

| material | aluminium |

| color | silver, white, wood |

| sample | free offered |

| usage | door and window |

| MOQ | 5tons |

| surface treatment | powder coated / anodize |

| process | aluminium cutting |

| delivery time | 15-20days |

| shipping port | shanghai / ningbo |

| payment | T/T, Western Union, L/C |

| packing | shrink film |

if you want buy new products,we also can make moulding to produce for you,

we have own factory can produce plastic parts and die casting and metal products.

We are manufacturer for door and window handle, lock,hinge, roller, window operator, plastic parts,gasket, weather seal strip, screw, rivets, glass, pvc door, aluminium profile,door clsoer, crescent lock.

- Q: Surface treatment method of aluminium profile

- Five most common surface treatment methods for aluminum profilesFabric: Aluminum matte matte surface aluminum profile Aluminum Alloy to avoid the presence of light interference will form light environment, under the condition of building decoration in the shortcomings of its surface such as brocade as soft and delicate, very popular with the favor of the market, but the existing grinding material must overcome the uneven surface of the sand, and can see the lack of pattern.Multi color surface treatment of aluminum: the monotonous white and tinted silver has been unable to meet the good cooperation of architects and the exterior decorative tile, exterior wall latex, new stainless steel color, champagne, gold, gold, titanium series (red wine, red jujube red, black, purple etc.) plus color glass the decorative effect of the icing on the cake. These shapes must be chemically or mechanically polished and then oxidized to better effect.Electrocoating aluminium profiles: electrophoretic coating profiles of surface soft luster, can resist the erosion of acid rain, cement mortar, Japan 90% aluminum after electrophoretic coating.Powder electrostatic spraying aluminum profile: powder electrostatic spraying profile is characterized by excellent corrosion resistance, acid, alkali, salt fog is much better than oxidation coloring section.Plasma enhanced electrochemical surface ceramic aluminum profile: this type of material is the most advanced processing technology in the world today. The profile products are of good quality, but the cost is higher. It has more than 20 kinds of colors, the biggest feature is that it can be printed as needed according to the printing cloth, the surface of the section is colourful and the decoration effect is excellent.

- Q: Is it possible to recycle and reuse aluminum profiles?

- <p>Yes, aluminum profiles can be recycled and reused. Recycling aluminum is an efficient and environmentally friendly process, as it requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains its properties, making it suitable for various applications. The recycling process involves melting the aluminum, which can then be reformed into new profiles without losing its strength or quality. This practice reduces waste and conserves natural resources, contributing to sustainability efforts.</p>

- Q: Is it possible to recycle aluminum profiles repeatedly without a substantial loss in their quality or functionality?

- <p>Yes, aluminum profiles can be recycled multiple times without significant degradation in performance. Aluminum is highly recyclable, and the recycling process does not compromise its properties. In fact, recycled aluminum maintains the same strength, durability, and malleability as new aluminum. This makes it an environmentally friendly material, as it reduces the need for mining new aluminum and conserves resources.</p>

- Q: Can aluminum profiles be used for skylights?

- Yes, aluminum profiles can be used for skylights. Aluminum is a popular material choice for skylight frames due to its durability, strength, and resistance to corrosion. It is lightweight yet sturdy, making it suitable for supporting the weight of skylight glass while ensuring long-lasting performance. Additionally, aluminum profiles can be easily customized and shaped to meet specific design requirements, allowing for various skylight styles and sizes. The use of aluminum profiles in skylights also provides excellent thermal insulation properties, contributing to energy efficiency by reducing heat transfer and preventing condensation. Overall, aluminum profiles are a reliable and practical option for constructing skylights.

- Q: Can aluminum profiles be used in signage and display applications?

- Yes, aluminum profiles can definitely be used in signage and display applications. Aluminum is a lightweight and versatile material that offers many benefits for these purposes. It is durable, corrosion-resistant, and can withstand various weather conditions, making it suitable for both indoor and outdoor applications. Aluminum profiles can be easily customized in terms of shape, size, and finish, allowing for the creation of unique and eye-catching signs and displays. Additionally, aluminum profiles can be easily assembled and disassembled, making them convenient for transportation and installation. Overall, aluminum profiles provide a great solution for signage and display applications due to their durability, versatility, and aesthetic appeal.

- Q: Explain the various uses of aluminum profiles in architectural design.

- <p>Aluminum profiles have a wide range of applications in architectural design due to their strength, durability, and versatility. They are commonly used for curtain walls, which provide a sleek and modern appearance while offering thermal insulation. Aluminum profiles are also used in window and door frames for their lightweight and strong properties, enhancing security and energy efficiency. They are integral in the construction of sun shading systems and louvers, which help control light and heat in buildings. Additionally, aluminum profiles are used in structural components like beams and columns, as well as in decorative elements such as facades and balustrades, offering both functional and aesthetic benefits.</p>

- Q: How to calculate the spraying powder of aluminium profile?

- Powder consumption is calculated according to the thickness of the coating film, powder density according to 1.2-1.6g/ cm fand effective coating rate of 50-70% formula, don't I teach.

- Q: Can aluminum profiles be used in the production of transportation containers?

- Yes, aluminum profiles can be used in the production of transportation containers. Aluminum is a lightweight and durable material that is widely used in various industries, including transportation. It offers several advantages for container production, such as corrosion resistance, high strength-to-weight ratio, and ease of fabrication. Aluminum profiles can be used to construct the framework and walls of transportation containers, providing structural integrity while keeping the overall weight of the container low. Additionally, aluminum profiles can be easily customized and shaped to fit specific container requirements. Overall, the use of aluminum profiles in transportation container production offers numerous benefits and is a popular choice among manufacturers.

- Q: Can aluminum profiles be used for signage?

- Signage can indeed utilize aluminum profiles. Aluminum, a material known for its versatility and durability, is commonly utilized in various signage applications. It boasts numerous advantages, including its lightweight nature, resistance to corrosion, and ease of manipulation. Aluminum profiles can be effortlessly shaped into diverse forms and sizes, rendering them suitable for a vast array of signage needs. Furthermore, these profiles can be powder coated or painted to attain the desired color and finish, thereby enhancing the signage's overall appearance. Notably, aluminum is an environmentally friendly option for signage projects as it is highly recyclable, contributing to its sustainability. All in all, due to their durability, versatility, and aesthetic appeal, aluminum profiles remain a favored choice for signage projects.

- Q: This question asks about the typical applications of aluminum profiles within the field of architectural design.

- <p>Aluminum profiles are commonly used in building design for various structural and aesthetic purposes. They are utilized in curtain walls, window frames, and door systems for their strength and lightweight properties. Additionally, aluminum profiles are employed in the construction of balconies, handrails, and sunshades due to their durability and resistance to corrosion. They are also used in interior design for creating partition walls, ceiling systems, and decorative elements. The versatility of aluminum profiles allows them to be easily adapted to different architectural styles and requirements, making them a popular choice in modern construction.</p>

Send your message to us

LED Aluminum Profiles for Furniture - Aluminium Rectangular Tubes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords