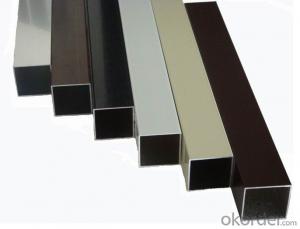

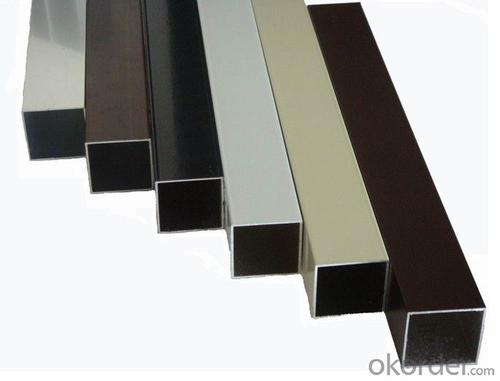

Painted Aluminium Square Tube Profile used on Furnitures

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Aluminum Square Tubes

1: Extrusion tooling free!

2: Fast lead time!

3: Guaranteed quality!

Aluminum Square Tubes

Dongke Aluminum has many existing toolings, please do not hesitate to contact us. Our professional and very amenable Dongkers are at your service!

1-Chemical Composition Of Aluminum Alloy

| Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | 0.45-0.9 | <0.35< td=""> | < 0.1 | < 0.1 | < 0.1 | < 0.1 | < 0.1 | < 0.05 | < 0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.8-1.2 | <0.7< td=""> | 0.15-0.4 | < 0.15 | < 0.25 | 0.04-0.35 | < 0.15 | < 0.05 | < 0.15 | Surplus |

2- Chemical Properties Of Aluminum Alloy

| Alloy | Temper | Thickness | Intensity streching resistance 6b (Mpa) | Intensity of bending 6p0.2(Mpa) | Stretching rate | T of tested samples (mm) | HV | HW |

| ≥ | ||||||||

| 6063 | T5 | All | 160 | 110 | 8 | 0.8 | 58 | 8 |

| 6061 | T6 | All | 205 | 180 | 8 | 0.8 | 90 | 15 |

- Q: Are aluminum profiles suitable for use in the defense industry?

- Yes, aluminum profiles are suitable for use in the defense industry. Aluminum is a lightweight, yet strong material that offers excellent corrosion resistance and high durability. It is commonly used in the defense industry for applications such as military vehicles, aircraft structures, and weapon systems. Additionally, aluminum profiles can be easily customized and fabricated to meet specific requirements, making them a versatile choice for defense applications.

- Q: What is the difference between 6061-T6 and 6063-T6 in aluminum profile?

- Alloy composition is different, 6061 of the other alloy composition is much higher than 6063.

- Q: What is the maximum length of aluminum profiles available?

- The maximum length of aluminum profiles available can vary depending on the supplier and specific requirements, but it is typically around 6 meters (20 feet).

- Q: Does aluminum alloy profile conduct electricity?

- Aluminum conducts well, and aluminium alloys must also be electrically conductive. But aluminum alloys contain impurities such as silicon and magnesium

- Q: What are the potential effects on the environment when aluminum profiles are used in the construction of buildings?

- <p>The use of aluminum profiles in building construction has both positive and negative environmental impacts. On the positive side, aluminum is lightweight, which reduces the energy required for transportation and can contribute to a building's energy efficiency. It is also recyclable, with a high recycling rate, which helps to conserve resources and reduce waste. However, the production of aluminum is energy-intensive and generates greenhouse gas emissions. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The environmental impact of using aluminum profiles in construction must therefore be balanced against these factors.</p>

- Q: This question asks for guidance on selecting the appropriate aluminum profile for a construction project.

- <p>To choose a suitable aluminum profile for your building project, consider the following: First, assess the structural requirements such as load-bearing capacity and span. Second, consider the aesthetic preferences and the desired finish or color. Third, evaluate the environmental conditions the profile will be exposed to, such as weather resistance and corrosion. Fourth, consult with suppliers or manufacturers for technical specifications and recommendations. Fifth, ensure compliance with building codes and standards. Finally, factor in the cost and availability of the profiles. It's often helpful to consult with engineers or architects who can provide expert advice tailored to your specific project needs.</p>

- Q: How are aluminum shapes made?

- 1, is the first process of production of aluminum casting. The main process is: (1) batching: according to the needs of the production of specific alloy grade, calculated the addition of various alloy ingredients, reasonable collocation of various raw materials. (2) smelting: the raw material is added into the melting furnace according to the process requirements, and the impurity and gas in the melt can be removed effectively through degassing and slag refining. (3) casting: molten aluminum liquid, in a certain casting process conditions, through the deep casting system, cooling casting into various specifications of round cast bar.

- Q: Are aluminum profiles compatible with other materials for construction purposes?

- <p>Yes, aluminum profiles can be used in combination with other materials in construction. They are often paired with steel, glass, and various plastics due to their lightweight, durability, and corrosion resistance. Aluminum's ability to be easily joined and its compatibility with different finishes make it a versatile choice for construction projects.</p>

- Q: Can aluminum profiles be used in retail store fixture manufacturing?

- Without a doubt, retail store fixture manufacturing can certainly make use of aluminum profiles. The retail industry widely embraces aluminum profiles due to their adaptability and long-lasting nature. These profiles can be easily personalized to fabricate a variety of fixtures, such as display shelves, clothing racks, signage frames, and product showcases. Aluminum profiles offer numerous benefits for retail store fixture manufacturing. Firstly, they are lightweight, allowing for effortless handling and installation. This facilitates swift and efficient assembly and rearrangement of fixtures. Secondly, aluminum profiles exhibit remarkable resistance to corrosion, guaranteeing durability and minimal maintenance. Moreover, they are available in an array of finishes, enabling customization to match the store's aesthetic. Additionally, aluminum profiles provide excellent structural strength, which is crucial for supporting heavy merchandise and ensuring customer safety. They can be effortlessly shaped and connected using various joining techniques, facilitating the creation of intricate fixture designs. Furthermore, aluminum is a sustainable material as it can be recycled, making it an environmentally conscious choice for retail store fixture manufacturing. This aligns with the growing sustainability trend in the retail industry. In conclusion, aluminum profiles are an ideal option for retail store fixture manufacturing due to their adaptability, durability, lightweight nature, corrosion resistance, customization options, structural strength, and sustainability.

- Q: What specific coatings or treatments are necessary for aluminum profiles to be used outdoors?

- <p>For outdoor use of aluminum profiles, special coatings or treatments are often required to protect against weathering, corrosion, and UV damage. Anodizing is a common process that increases the durability and resistance of aluminum. Powder coating is another method used for additional protection and to provide a wide range of colors. Some profiles may also be treated with a clear coat to maintain the natural look of aluminum while still offering protection. It's important to select the appropriate treatment based on the specific environmental conditions and aesthetic requirements of the application.</p>

Send your message to us

Painted Aluminium Square Tube Profile used on Furnitures

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords