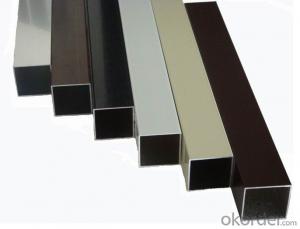

Hafele Aluminum Profiles for Furniture Square Pipes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

aluminium profile tube for construction

1.Square tube aluminium extrusion for door and window

2.aluminum window frame extrusion

3.aluminum extrusion profiles

| material | aluminium |

| color | silver, white, wood |

| sample | free offered |

| usage | door and window |

| MOQ | 5tons |

| surface treatment | powder coated / anodize |

| process | aluminium cutting |

| delivery time | 15-20days |

| shipping port | shanghai / ningbo |

| payment | T/T, Western Union, L/C |

| packing | shrink film |

if you want buy new products,we also can make moulding to produce for you,

we have own factory can produce plastic parts and die casting and metal products.

We are manufacturer for door and window handle, lock,hinge, roller, window operator, plastic parts,gasket, weather seal strip, screw, rivets, glass, pvc door, aluminium profile,door clsoer, crescent lock.

- Q: Can aluminum profiles be used in the construction of amusement park rides?

- Yes, aluminum profiles can be used in the construction of amusement park rides. Aluminum is a popular choice for constructing various components of amusement park rides due to its lightweight and durable properties. The profiles can be easily shaped and welded to create complex structures, such as roller coaster tracks, supports, and frames for other rides. Aluminum's corrosion resistance also makes it suitable for outdoor environments where the rides are exposed to weather conditions. Additionally, aluminum is a sustainable material as it can be recycled, making it an environmentally friendly choice for amusement park ride construction. Overall, aluminum profiles provide a versatile and reliable option for creating safe and exciting amusement park rides.

- Q: What is the thickness of the aluminum alloy window frame?

- According to the provisions of GB5237.1-2008, aluminum profile wall thickness not less than 1.2mm. The size of the wall must be calculated after the pressure bearing is calculated.

- Q: Explain the various uses of aluminum profiles in architectural design.

- <p>Aluminum profiles have a wide range of applications in architectural design due to their strength, durability, and versatility. They are commonly used for curtain walls, which provide a sleek and modern appearance while offering thermal insulation. Aluminum profiles are also used in window and door frames for their lightweight and strong properties, enhancing security and energy efficiency. They are integral in the construction of sun shading systems and louvers, which help control light and heat in buildings. Additionally, aluminum profiles are used in structural components like beams and columns, as well as in decorative elements such as facades and balustrades, offering both functional and aesthetic benefits.</p>

- Q: What specific considerations or criteria must be met when using aluminum profiles in the construction of high-rise buildings?

- <p>Yes, there are special requirements for using aluminum profiles in high-rise buildings. These include high strength and load-bearing capacity to withstand the weight and wind forces. Durability is crucial to resist corrosion and weathering over time. Fire resistance is also important for safety. Additionally, aluminum profiles must comply with building codes and regulations specific to high-rise structures. They should also have good thermal insulation properties to maintain energy efficiency and comfort. Lastly, aesthetic considerations are important as the profiles contribute to the building's exterior appearance.</p>

- Q: Can aluminum profiles be used in warehouse and storage systems?

- Yes, aluminum profiles can be used in warehouse and storage systems. Aluminum profiles are lightweight, durable, and corrosion-resistant, making them suitable for various applications in warehouses and storage systems. They can be used to construct shelving units, racks, and partitions to optimize storage space and organize inventory. Aluminum profiles are also known for their versatility, as they can be easily customized and assembled to meet specific storage requirements. Additionally, aluminum profiles offer excellent strength-to-weight ratio, allowing them to support heavy loads without compromising structural integrity. Overall, aluminum profiles are a popular choice in warehouse and storage systems due to their durability, flexibility, and cost-effectiveness.

- Q: This question asks for a method to determine the quantity of aluminum profiles needed for a construction project.

- <p>To calculate the amount of aluminum profiles required for a building project, follow these steps: 1. Determine the project's design and specifications to identify where aluminum profiles are needed. 2. Measure the dimensions of the areas requiring aluminum profiles (length, width, height). 3. Calculate the total linear footage needed by multiplying the dimensions. 4. Consider the profile's cross-sectional area and the project's load-bearing requirements. 5. Account for waste and additional material for joints, connections, and potential errors. 6. Consult with suppliers or use industry-standard formulas to determine the exact quantity of profiles needed. 7. Review and adjust calculations as the project progresses to ensure accuracy.</p>

- Q: Can aluminum profiles be custom-designed or customized?

- Yes, aluminum profiles can be custom-designed or customized according to specific requirements. Aluminum is a highly versatile material that can be easily shaped and manipulated into different forms. Customizing aluminum profiles allows for the creation of unique shapes, sizes, and finishes to meet the specific needs of various applications. Custom design and customization of aluminum profiles can involve altering dimensions, creating intricate shapes, adding slots or holes for assembly, incorporating specific features or accessories, and even applying various surface treatments or coatings. This flexibility in design and customization enables aluminum profiles to be used in a wide range of industries and applications, such as construction, automotive, aerospace, electronics, and more. The process of customizing aluminum profiles typically involves collaboration between the manufacturer and the customer. The manufacturer will work closely with the customer to understand their requirements, provide technical support, and offer design solutions that meet their specific needs. This may include creating prototypes, conducting tests, and making adjustments until the desired custom design is achieved. Overall, aluminum profiles can indeed be custom-designed or customized to suit specific requirements, making them a preferred choice for many industries seeking unique and tailored solutions.

- Q: Can aluminum profiles be used in noise insulation applications?

- Indeed, noise insulation applications can indeed make use of aluminum profiles. These profiles possess remarkable versatility and can be specifically engineered to exhibit exceptional acoustic properties. Consequently, they can serve as the foundation for constructing soundproof windows, doors, walls, and enclosures. By combining aluminum profiles with materials such as acoustic glass, rubber seals, and insulation foam, their noise insulation capabilities can be further enhanced. Moreover, owing to aluminum's inherent strength and durability, it is perfectly suited for deployment in noise insulation applications, as it can withstand the pressures and vibrations generated by sound waves. In summary, aluminum profiles represent a feasible solution for fulfilling noise insulation requirements across various settings, including residential, commercial, and industrial buildings.

- Q: Which is the highest price of aluminum profile 60616063?

- 6063 general construction profiles, that is industrial profiles

- Q: What are the various standards and regulations governing the use of aluminum profiles in construction?

- <p>Aluminum profiles in construction are governed by a variety of standards and regulations that ensure their quality, safety, and performance. These include ISO standards such as ISO 7039 for anodized aluminum and ISO 9001 for quality management systems. National standards like ASTM B221 in the USA and EN 755 in Europe specify mechanical properties and chemical composition. Building codes such as the International Building Code (IBC) and Eurocode 9 also provide guidelines for the use of aluminum in construction. Additionally, there are specific regulations for fire resistance, sustainability, and environmental impact, like the European CE marking for construction products. Compliance with these standards is crucial for manufacturers and builders to ensure the reliability and safety of aluminum profiles used in construction projects.</p>

Send your message to us

Hafele Aluminum Profiles for Furniture Square Pipes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords