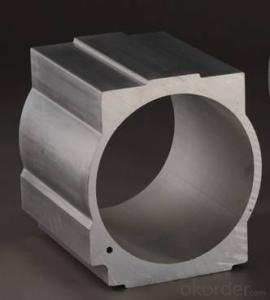

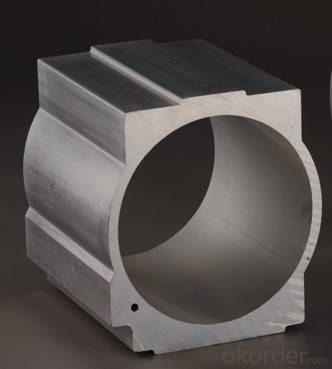

Aluminum Pipe Air Cylinder Shell

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, Mill,rtc |

Colour | Mill |

Length | -- |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Air cylinder shell; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: The air conditioner is broken in the middle of the aluminum tube. How can I weld it?

- There are two kinds of welding methods for aluminum pipe.Method: gas, liquefied gas welding gun with WE-Q303 low temperature aluminum wire.Method two: AC argon arc welding, argon arc welding with aluminum argon arc welding machine.

- Q: 1100 what is the difference between the aluminum tube and the 6063 material aluminum tube, please advise

- The 1100 is rust proof aluminum grades, good corrosion resistance, good plasticity, but the intensity is the lowest, 6063 forging Aluminum Alloy, is Aluminum Alloy, if after solid solution treatment and aging, high strength and hardness, but the corrosion resistance of less than 1100,

- Q: Can aluminum pipes be painted or coated?

- Aluminum pipes have the capability of being painted or coated. Aluminum, being a versatile material, can easily be painted or coated to improve its appearance or provide extra protection. To ensure good adhesion of the paint or coating, it is vital to adequately prepare the surface by cleaning and degreasing it. It is also advisable to use a primer specifically designed for aluminum surfaces, as it enhances adhesion and durability. The selection of paint or coating depends on the desired outcome and the specific application of the aluminum pipes. For instance, for exterior use, it is crucial to opt for a paint or coating that is resistant to UV rays and weathering. Overall, by properly preparing the surface and using suitable paints or coatings, aluminum pipes can be effectively customized to meet various requirements.

- Q: I have 6 60CM long diameter 5MM aluminum tubes, which are used on the model. I want to take it home. It is too small for me to take a plane. Can I take it with me? For advice, fly from Nanjing, transfer in Xi'an, check security two times.

- In general can not carry only checked, you can specify at check-in, see if you can carry, if not, the airport where there are special packing, good consignment packaging.

- Q: What are the different pressure testing methods for aluminum pipes?

- There are several pressure testing methods that can be used for aluminum pipes to ensure their integrity and reliability. 1. Hydrostatic Testing: This is the most common and widely used method where the aluminum pipe is filled with water or another liquid and pressurized to a predetermined level. The pipe is then inspected for any leaks or abnormal behavior under pressure. Hydrostatic testing is relatively simple, cost-effective, and provides accurate results. 2. Pneumatic Testing: In this method, air or inert gas is used to pressurize the aluminum pipe instead of liquid. The pipe is sealed and the pressure is increased gradually until the desired test pressure is reached. The pipe is then inspected for any leaks or deformation. Pneumatic testing is often used when water or other liquids might be detrimental to the pipe material. 3. Ultrasonic Testing: This method utilizes ultrasonic waves to detect any flaws or defects in the aluminum pipe. Transducers are used to transmit and receive the ultrasonic waves, and any changes in the waves' characteristics indicate the presence of defects. Ultrasonic testing is non-destructive and can be done without applying pressure to the pipe. 4. Magnetic Particle Testing: This method is specifically used to detect surface cracks or defects in aluminum pipes. A magnetic field is created around the pipe, and finely divided magnetic particles are applied to the surface. If there are any surface defects, the particles will be attracted to those areas, making them visible for inspection. 5. Radiographic Testing: This method involves the use of X-rays or gamma rays to inspect the internal structure of aluminum pipes. The pipe is exposed to these rays, and the resulting image is analyzed for any defects or abnormalities. Radiographic testing is highly accurate but requires specialized equipment and trained personnel. It is important to note that the choice of pressure testing method for aluminum pipes depends on various factors such as the specific application, pipe size, material thickness, and industry standards. Consulting with experts or referring to industry codes and regulations is crucial to determine the most suitable testing method for a particular situation.

- Q: What is the chemical composition of aluminum pipes?

- Aluminum pipes consist mainly of aluminum, a chemical element represented by the symbol Al and atomic number 13. Aluminum is a versatile and lightweight metal recognized for its ability to resist corrosion, high thermal conductivity, and exceptional strength-to-weight ratio. To enhance its properties, aluminum is frequently combined with other elements. Copper, silicon, magnesium, and zinc are commonly used as alloying elements in aluminum pipes. Incorporating these elements can enhance the aluminum pipe's strength, hardness, and machinability. The exact chemical composition of aluminum pipes may differ depending on the desired properties and application specifications.

- Q: Can aluminum pipes be used for gas distribution?

- Yes, aluminum pipes can be used for gas distribution. Aluminum is a durable and lightweight material that is resistant to corrosion, making it suitable for various applications, including gas distribution. Aluminum pipes are commonly used in industries such as oil and gas, aerospace, and automotive, where they are used to transport different gases, including natural gas. Additionally, aluminum pipes have excellent heat conductivity and can withstand high pressures, making them a reliable choice for gas distribution systems. However, it is important to ensure proper installation and maintenance to prevent any potential issues such as leaks or damage to the pipes.

- Q: Can aluminum pipes be used for transporting liquids?

- Yes, aluminum pipes can be used for transporting liquids. Aluminum pipes are commonly used in various industries for fluid transportation due to their excellent corrosion resistance and lightweight properties. They are particularly suitable for transporting non-corrosive liquids such as water, oils, and certain chemicals. Aluminum pipes are also easy to install and maintain, making them a cost-effective choice for liquid transportation systems. However, it is important to ensure compatibility between the liquid being transported and the aluminum material to avoid any chemical reactions or damage to the pipes.

- Q: What are the advantages and disadvantages of steel tubes, aluminium tubes and stainless steel pipes?

- You should first find out the material brand, and then find manufacturers to test specimens to do material reports, and then consult the materials manual or the corresponding national standards to control whether it meets the requirements of the standard!

- Q: I have used ab repair several times, each time with only three months and leakage of fluorine, hope you master generous with your criticism,

- Aluminum tube evaporator if not leak greatly, I have been using A&B glue + Gauze trap, the effect is quite good, do test pressure 2.5MPa can withstand.Best not to glue, time is not too long and bad, they also said that you repair is not good, from the leak to expand into the bell mouth, with 8 pairs of silk butt, economical and easy to use.10 cm 6 mm copper inserts 5 cm (with torch heating), then the vacuum side at the joints' three 'drop gum (similar to 502, but better than the 502), then AB wrapped in gauze dipped in the outer two or three layers can be.

Send your message to us

Aluminum Pipe Air Cylinder Shell

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords