Air Powered Hydraulic Cylinder

Air Powered Hydraulic Cylinder Related Searches

Telescoping Hydraulic Cylinder Hydraulic Automobile Lift Hydraulic Lift Automotive Air Filling Pump Cylindrical Thrust Bearing Hydraulic Block Machine Air Actuated Butterfly Valve Air Duct Balancing Hydronic Tubing Hydrostatic Machine Swimming Pool Air Pump Hydraulic Pile Hammer Automatic Sliding Door Controller Air Duct System Waterproof Admixture Concrete Hydronic Boiler Air Duct Engineering Air Pump Tube Solar Powered Water Boiler High-Pressure Compressor Hydraulic Piling Rig Machine Heating Air Ducts Hydraulic Excavator Training Air Bubble Packaging Machine Automatic Washing Machine Air Conditioning Installation Air Pump For Aquarium Purpose Submersible Chemical Pump Air Duct Air Pump AttachmentsAir Powered Hydraulic Cylinder Supplier & Manufacturer from China

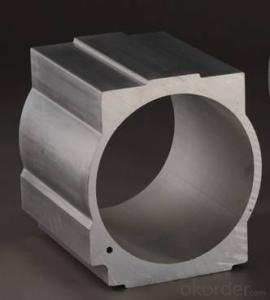

Air Powered Hydraulic Cylinders are a type of mechanical device that utilize compressed air to generate hydraulic pressure, resulting in the movement of a piston within a cylinder. These devices are engineered to provide a reliable and efficient means of converting air pressure into mechanical force, making them ideal for various industrial applications. They are widely used in scenarios where precise control and force generation are required, such as in manufacturing processes, construction equipment, and material handling systems.Air Powered Hydraulic Cylinders find their application in a multitude of industries due to their ability to deliver consistent and controlled force. They are particularly useful in situations where electrical power is not readily available or where there is a need for a safer and more environmentally friendly alternative to traditional hydraulic systems. These cylinders can be found in use in various machinery, from lifting and lowering heavy loads to controlling the movement of mechanical arms in assembly lines.

Okorder.com stands as a prominent wholesale supplier of Air Powered Hydraulic Cylinders, boasting a vast inventory that caters to the diverse needs of customers across different sectors. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Air Powered Hydraulic Cylinders they provide meet the highest industry standards. Their extensive range and competitive pricing make them a go-to source for businesses looking to equip their operations with reliable and efficient hydraulic solutions.