Vertical Axial/Mixed Flow Propeller Pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vertical Axial/Mixed Flow Propeller Pump Introduction

QZ series axial-flow pumps are modern products successfully designed through adopting foreign modern technology. The new pumps’ capacity are 20% larger than the old ones. The efficiency is 3%-5% higher than the old ones. QZ series pump with adjustable impellers has the advantages of large capacity, broad head, high efficiency, wide application and so on. Pump station is small in scale, the construction is simple and the investment is greatly decreased. This can save 30%-40% for the building cost. It is easy to install,maintain and repair this kind of pump. Low noise,long life.

Vertical Axial/Mixed Flow Propeller Pump Parameter

QZ series axial-flow pump is applicable for water supply in cities, diversion works, sewage drainage system, sewage disposal project.

Propeller Pump Technical Data:

Flow rate: up to 20 m³/h

Head: up to 20 m

Speed: max rpm

Temperature: max °C

Casing pressure: up to MPa

Shaft seal: mechanical sealing

Material: nodular iron, stainless steel, duplex

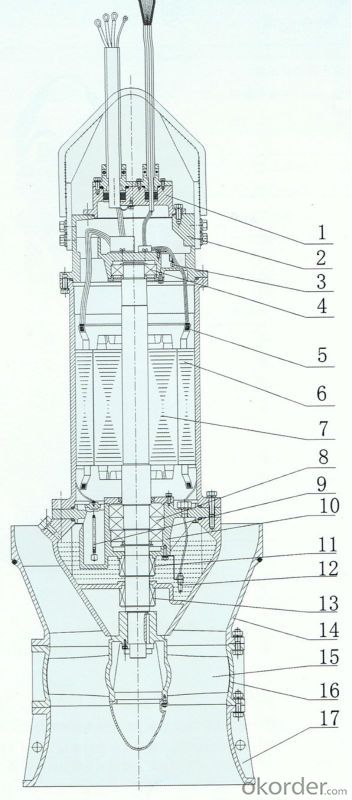

Vertical Axial/Mixed Flow Propeller Pump Structure

NO. | Name | Material | NO. | Name | Material |

1 | Terminal Cover | FC250 | 10 | Gland Cover | FC250 |

2 | Gland Cover | FC250 | 11 | Upper Mech Seal | Graphite/Sic |

3 | Leakage Alarm | Standar | 12 | Electrode Probe | standar |

4 | Bearing | Heavy duty | 13 | Down Mech Seal | Sic/Sic |

5 | Heat Protector | standar | 14 | Guide Vane | FC250 |

6 | Stator | FC250 | 15 | Propeller | SUS304 |

7 | Rotor | SUS420 | 16 | Casing | FC250 |

8 | Bearing | Heavy duty | 17 | Suction Horn | FC250 |

9 | Leakage Alarm | Standard |

- Q: My 2001 300M is behaving oddly. Occasionally it will gradually overheat after I have driven around for 15 or so minutes. Yes, occasionally. I took it to my mechanic who changed the thermostat and hoses. I then drove it on a trip on the interstate and over a mountain (140 miles ) It was fine with no signs of overheating. Then the next day when I drove to work in the city, the stop and go traffic had it overheating near the end of the trip. I've been able to keep it from going in the red by using the heater. After this happened most of the days, but not all, I took it back to the shop. He reported that the fans were working correctly and the only thing he could come up with is a weak water pump. He stated that when it did get hot, he was able to bring the temp down just by rev'ing the engine a little.Does that sound right? Any other ideas and how to test?

- Sounds precisely like your water pump. I had the identical predicament with a cavalier. The pump shoud be around $30 to $50 or so. Price to alter? Quite often around $one hundred to $150. Might be extra so don't quote me on that. Every keep has their own hourly cost.

- Q: the pump is pumping hot wtaer from the hot water tank around the domestic hot water system, i.e to taps and shower.

- These pumps can have their own bearing or they may rely on the bearings in the motor. Most of these are anti-friction bearings that have a limited life. Also if the pump runs dry it can over heat and seize.

- Q: my water pump is leaking and chirping would like to know the procedure

- Drain the coolant. Remove fan clutch. Remove radiator shroud. Remove serpentine belt. Disconnect top and bottom radiator hoses. Disconnect bypass and heater hose. Remove the pump bolts. Remove the pump. Clean all old gasket material off block. Reverse to install! Be sure to use anaerobic sealer on the bolts that enter into the water passages. It's a good idea to replace the thermostat at this time, and flush the radiator and block, as well as use new coolant.

- Q: How to measure the temperature of pump body?

- It's the temperature of the pump motor!In addition to large pumps, water temperature is rarely monitored. Even so, the temperature of the pump body will not be measured.Since the water pump pumping, the leaves, vanes and shells are no temperature rise, the temperature is mainly concentrated in the bearing: small pumps rely on the work medium can play a role in reducing friction heat;Heating large pump mainly in the thrust bearing and guide bearing, if the bearing is lubricated by water cooling water, if there is oil lubricated oil cooling equipment specially, temperature monitoring of bearing large pumps can be installed in the pump thrust bearing temperature sensor to monitor the varnay.

- Q: the outboard runs fine and pumps water out with muffs on but when i put it in the water it doesn't pump any water at all. could it be that the impeller needs replacing? what do you think?thanks

- Replacing okorder /

- Q: I know that the water pump is belt driven, so it would be easy to connect it to my bicycle. What I am wondering is if I can pedal fast enough to make it work. Does anyone know how fast I would need to pedal to operate the pump?

- Pretty fast. Engines operate at 600-6000 rpm and the pump pulley is a little smaller than the drive pulley, so it is spinning even faster. That said, 600 rpm is plenty fast enough. You can attain that easily by applying pulley to rear tire tread, raising tire off ground and pedaling. To apply bike chain to pulley would give a disappointing water flow.

- Q: Which is the better option for a home water pump? a submersible pump or floor based pump?

- In case of pump failure, it's much easier to repair/replace a floor based pump plumbed with isolation valves and unions. I've replaced a few due to motor failures and flood damage. Arguably, the submersible pump wouldn't have suffered damage due to flooding. Another consideration is vertical pump height. A floor based pump has to draw a vacuum to induce water to flow up to the impeller. This limits the practical draw to between 25 and 30 ft. Much more than that height and the vacuum will exceed the vapor pressure of the the water, boiling it rather than pumping it. A special device can be used to boost the lift: an ejector is placed down the well. Water is pumped down to the ejector, which pulls additional water back up using the venturi effect. This method suffers from additional friction losses but has clear advantages. If you need to pump water up a well more than 20 feet vertical, you should consider a submersible pump, particularly if you are concerned about the possibility of the water table lowering.

- Q: I have a slight idea but I would like to see what steps other people have taken. I have a 1992 ford escort that needs a new water pump, what steps have you taken to replace it?

- if you're going to do it yourself first I recommend getting the book for the car sometimes the library will have them..you also want to be careful when changing the water pump because your timing belt is hooked up to the water pump. If you misalign the camshaft or the crankshaft pulleys or turn them independently when the belt is off you can cause damage to the head of the engine (very important: your timing will be off..you don't want that). To start with though, you will have to take off your accessory belt and the accessory crank pulley, then take off the timing belt cover and use the crank shaft pulley to line up the marks that are on the pulley and the engine (on both the crankshaft pulley and the cam shaft pulley) carefully take the timing belt off (replace the timing belt and the timing belt tensioner..trust me it'll be worth it). You're going to have to drain the antifreeze before you take the water pump off. (I would also replace the thermostat because its cheap and you already have the fluid out) The install is pretty much the opposite. (again make sure the marks line up on the cam and crank pulleys and don't turn them independently when you're putting the belt back on) (short answer: get the book and/or have someone that's done it before help) when your done you can say you did it :)

- Q: How important is a torque wrench,if so what is the proper fp torque for pump/pulley ?

- dont need to tighten until good and snug torque is critical on head bolts and bearing cap and rod cap bolts etc

- Q: I have a 1997 mazda 626 4cylinder. For a while now, my hot n cold gauge keeps wobbling back and forth. I was keeping water in it and it was fine. A week ago it went all the way to hot and started smoking. There is water gushing out right beside the pulleys. I'm not sure if it is the water pump or not. Now, my car won't crank. Someone told me that it was the rotor button, but i can't tell if it is bad. I don't really want to take it to a mechanic. Can someone help me?????

- your water pump is bad if it leaks or whines. Sounds like yours leaked when you rcar overheated. I'd suggest that the overheating problem may have been caused by something else though, as you said that the water levels were not going down until it overheated. I would suggest you may have had a head gasket problem or thermostat or radiator problem. Now it sounds like you have done a lot of damage by allowing it to get so hot. You may have a ruined engine I'm afraid. It might have seized. Tip;- don't carry on driving when it keeps overheating. It does a lot more expensive damage if you do. Take your car to a professional to get it checked out. Expect the worse. Sorry to sound so gloomy, but I'm just trying to prepare you. I hope for your sake it isn't as bad as I think. Good Luck

Send your message to us

Vertical Axial/Mixed Flow Propeller Pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords