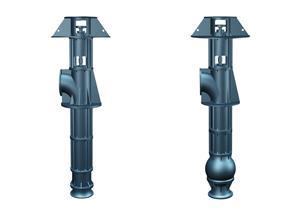

ZLB Vertical Axial/mixed Flow Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Summary

Z(H)LB vertical axial-(mixed)-flow pump is a new general-eration product successfully developed by this Company by means of introducing the advanced foreign and domestic know-how and meticulous designing on the basis of the requirements from users and the conditions of use. This series product uses the latest excellent hydraulic model, wide range of high efficacy, stable performance and good vapor erosion resistance; the impeller is precisely cast with a wax mould, a smooth and unimpeded surfac e, identical accuracy of the cast dimension to that in design, greatly reduced hydraulic friction loss and shocking loss, a better balance of impeller, a higher efficiency than that of the common impellers by 3-5%.

Flow:800~200000m /h

Head:1~30.6m

Power:18.5~7000kW

Voltage: 355kW 6kV 10kV

Frequency:50Hz

Extensively used for hydraulic projects, farm-land irrigation, industrial water transportation, water supply and drainage of cities and water allocation engineering.

Suitable for pumping pure water or other liquids of the phy-sical chemical natures similar to those of pure water.

Medium temperature: <50

Medium density: <1.05 x 10 kg/m

PH value of medium:between 5~11

ZLB(Q),HLB(Q) series products are all of a vertical structure and fitted with a vertical motor, With the impeller there are fixed, semi-adjustable and fully-adjustable type. The fixed type means

both impeller and hub are cast integrally and the impeller angle is unadjustable; the semi-adjustable type means the impeller can be turned to the desired angle by loosening the fixing screw on it in case the working conditions need to be changed, then fix all the impellers again; Z(H)LQ is the fully-adjustable type, that means the impeller angle can be adjusted through a mechanical or hydraulic adjustor with or without stopping.

Vertical axial-(mixed)-flow pump consists of the pump casing and the actuating part. The pump casing generally includes water inlet pipe, impeller, guide vane, pump shaft, elbow, middle pipe, sealing unit and clutch. For both middle and small pumps, a water inlet horn is used as the water inlet pipe while, for the large one, a toggle or bell water inlet passage is used, poured with concrete and fitted with imported basic parts. The adjustable impelle r is formed with blade(stainless steel or copper alloy, in general), hub, water guide cone. For the middle and small pumps, both impeller and pump shaft are connected with flat pin and nut whi le, for the large and fully adjustable ones, a flange is used to connect both hub and main shaft. The pump s guide bearing is a rubber one and can be lubricated with going-through water or additional pure water. When lubricated with the going-through water, it has to be done to supply water for the rubber bearing on the upper side via a water-led pipe and do not stop until water comes out of

the pump normally.

Both middle and small pumps are directly actuated by a vertical motor, the motor is mounted on the motor seat and connected wi th the actuating shaft via an elastic cluth. Inside of the motor seat there are radial and thrust bearings, lubricated with engine oil or grease; for the one of a bigger power there is a water cooling mezzanine. Large pump is fitted with a large vertical motor, directly mounted on the motor s basic beam, and both motor shaft flange and pump shaft flange (hinged hole) are linked with bolt. The axial force of the pump is borne by the thrust bearing of the large vertical motor.

The pump moves clockwise viewing from the motor

- Q: I have a 1969 Chrysler with a new 3 core radiator. It still has the stock water pump and I am wondering if a high volume pump would make it run cooler at higher speeds. It runs hotter when you get off the freeway. I have flushed the system and installed a new thermostat. I also replaced the fan clutch. I am at a loss of why it still runs warmer than the 180* thermostat.

- maybe the fan is too far away from the radiator to efficiency pull the air at slow speed. They sell spacers.

- Q: Who knows? Is the motor with a pump a squirrel cage induction motor?

- Should be a squirrel cage motor for winding asynchronous motor for high torque applications. For example, its structure and the hoist crane cage motor with different rotor loop it can slip ring external resistor. The motor rotor circuit principle know that certain external resistance can reduce the starting current, but also can improve the rotor circuit power factor and torque. The pump load does not need large torque. So it should be the squirrel cage induction motor.

- Q: 93 Cutless Sierra FWD

- For a 2.2 4 cylinder read below: Disconnect battery ground cable, then drain cooling system. Remove serpentine drive belt, then the alternator and bracket. Remove water pump pulley attaching bolts, then remove the pulley, Fig. 20. Remove water pump attaching bolts, then the water pump. Reverse procedure to install. For a 3.3 6 cylinder read below: Disconnect battery ground cable. Drain cooling system, then remove serpentine drive belt. Remove lower radiator hose and heater hose at pump. Remove water pump pulley attaching bolts. Long bolt is removed through access hole located in the body side rail. Remove water pump pulley. Remove water pump attaching bolts, then the water pump, Fig. 15. Reverse procedure to install, torquing bolts to specifications Hope this was helpful!

- Q: I'm not too familiar with computerized cars, just wondering if the water pump going out would cause the car not to start?

- Drain coolant, would would desire to eliminate coolant reservoir,next pull belt tensoner back and eliminate belt remembering the way its routed. next eliminate the bolts on w-pump pulley eliminate outer ring of bolts on pump. sparkling gasket setting up new one ,.bleed air from equipment to pevent overheat.desire that's stable.

- Q: hi, how long does the water pump last on e65 chassi 745i (miles)

- Usually car manufacturers estimate that most car parts (like a water pump) would last the warranty period and this means 40k to 50k miles. Original water pumps from dealers which are installed during car repairs are usually warrantied for 2 years. Of course this can be voided by driver abuse such as overheating the car or low coolant level.

- Q: We use this water pump for about 2 years, and in the last week the circuit breaker trip when we turn on the pump. What should I check first for the problem?

- When the pump motor starts, it engages a start winding that can draw enough current tripping the breaker in question. I would recommend that you change the breaker. It may have become weak after years of operation of said pump. It is a very good idea to dedicate a breaker for this motor. This configuration will insure that there's not another appliance in the circuit that may cause this problem of overloading said breaker when a limit switch closes to turn on the pump. Feel free to e-me.

- Q: I am planning to build a koi fish pond, and I know I need a water pump. All I know is that a water pump will circulates water. Does it do anything else? does it act like a filter? does it provide aeration or oxygen to the pond?

- It only circulates the water, nothing else. Also, make sure your pond won't be in sunlight the whole day. Sunlight makes algae grow. ~ZTM

- Q: I was wondering how to replace the water pump in a 94 Plymouth Voyager. Its my moms van and she is scared that they are going to have to pull the motor to get to the water pump to replace it. I dont know so i am hoping one of yall wonderful people do. along with your answers can you give me an estimate of how much it will cost to fix? Please!!!

- Your Grand Voyager is probably one of two engiones; either a 3.3L or a 3.8L. In either case, the pump is fairly straight forward and only requires a little over 1-1/2 hours to change. It is accessed from below the vehicle, from the right wheel-well.

- Q: can you replace a water pump gasket without replacing the whole water pump?

- Yes. Just make sure that the pump it-self is not leaking out of a small hole (aka weep hole) or the shaft that drives the pump. and romove the old gasket completly. clean very well. both pump and motor.

- Q: Could it make coolant quot;Boilquot;? Ive heard myc ar's behavior is Normal, and most likely just heavy condenstaion as it DOES go away, also the behavior of the coolant and the tank.. but i DO know the Water Pump is quot;Weeping,or quot;Seeping,so i wonder what interaction that would have ont he Cooling side of the motor; what effects can it produce? What would i notice?My 1991 Calais 2.5L quot;Iron Duke,

- Steam coming from your headlight on a rainy night is NORMAL, since the halogen bulb makes a lot of heat. This turns the water into water vapor, (steam) as it attempts to dry out. If you don't physically hear the bearings in your water pump, or watch colored fluid drip out from under your engine, then your water pump is JUST FINE!!! STOP WORRYING! I answered one of your questions the other day. If you take my advice, your engine will run at it's best. For extra protection, drain and flush your cooling system out, and use Mercedes coolant. Dex-cool has been proved to be a potentially bad coolant. READ the dexcool litigation websites. Mercedes coolant, which is YELLOW in color, will last for 150,000 miles, and is a time tested WINNER!!! Use ONLY top tier fuels (read about this on web) and use ONLY synthetic oil, like Mobil One. CLEAN your idle air control valve and throttle plate. AND STOP WORRYING!

Send your message to us

ZLB Vertical Axial/mixed Flow Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords