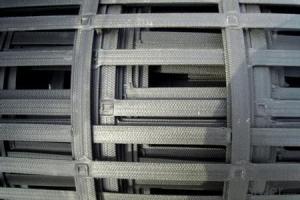

Multi Axial Geogrid

Multi Axial Geogrid Related Searches

Led For Cannabis Growing Fiberglass Sheets For Roofing Geogrid For Road Construction Geogrid For Erosion Control Geogrid For Soil Stabilization Geogrid For Horse Paddocks Geogrid For Gravel Geogrid For Pavers Geogrid For Steep Slopes Geogrid For DrivewaysHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleMulti Axial Geogrid Supplier & Manufacturer from China

Okorder.com is a professional Multi Axial Geogrid supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Multi Axial Geogrid firm in China.Hot Products

FAQ

- Two, fat and PVC paste resin paste into the sizing, coated on glass fiber cloth, so that after baking, how do not shrink?

- Diluent can also be added as a diluent substance is hydrocarbons, and their boiling point should be 100~200 degrees. But in any case, the boiling point of the diluent used should be lower than the dispersant. Some swelling effect of aromatics is on PVC resin, almost no Naphthalene Hydrocarbons, aliphatic hydrocarbon is not completely.

- Indeed, wet or humid environments can accommodate the use of fiberglass fabric. Regarded as an incredibly adaptable substance, fiberglass is renowned for its ability to withstand moisture and humidity. It possesses the remarkable quality of not absorbing water, rendering it impervious to the detrimental effects of mold or mildew. Consequently, it becomes an exceptional choice for various purposes such as constructing boats, manufacturing outdoor furniture, and providing insulation in regions prone to excessive moisture. Moreover, fiberglass fabric exhibits resistance to corrosion, thus rendering it suitable for deployment in marine settings or areas characterized by high salt content. On the whole, fiberglass fabric represents a robust and dependable alternative for utilization in wet or humid environments.

- Fiberglass fabric is an excellent choice for handling abrasion in mining operations due to its exceptional durability and resistance to wear and tear. In mining operations, where abrasive materials such as rocks, stones, and minerals are commonly encountered, fiberglass fabric stands up well to the harsh conditions. One of the key properties of fiberglass fabric is its high tensile strength, which enables it to withstand the constant rubbing and scraping against abrasive surfaces. The fabric's tightly woven structure provides a protective barrier, preventing the abrasive particles from penetrating the material and causing damage. Additionally, fiberglass fabric is highly resistant to chemical corrosion, which is often present in mining environments. It can withstand exposure to various acids, alkalis, and other corrosive substances commonly found in mining operations. This resistance ensures that the fabric remains intact and functional even when exposed to these harsh chemicals, further enhancing its durability against abrasion. Furthermore, fiberglass fabric is known for its excellent heat resistance, making it suitable for mining operations that involve high temperatures. It can withstand extreme heat conditions without losing its structural integrity or degrading in performance. This property is especially crucial in operations such as smelting, where intense heat is involved. Moreover, fiberglass fabric is lightweight and flexible, making it easier to handle and install in mining equipment. Its flexibility allows it to conform to irregular shapes and surfaces, ensuring a snug fit and maximum protection against abrasion. In summary, fiberglass fabric is an ideal choice for handling abrasion in mining operations due to its exceptional durability, resistance to wear and tear, chemical corrosion, and heat resistance. Its high tensile strength, flexibility, and lightweight nature make it a reliable and practical solution for protecting mining equipment and machinery from the abrasive forces encountered in these operations.

- HVAC systems are well aware of the exceptional performance of fiberglass fabric in extreme temperatures. This material is perfect for insulation because it can endure high temperatures without compromising its structural integrity or insulation properties. When it comes to hot environments, fiberglass fabric acts as a barrier, blocking the transfer of heat between different areas within the HVAC system. It effectively traps heat within the desired space, ensuring energy efficiency and minimizing heat loss. Similarly, in cold temperatures, fiberglass fabric functions as an insulator, preventing heat from escaping and maintaining a consistent temperature within the HVAC system. This reduces energy consumption and ensures optimal performance. Moreover, fiberglass fabric is fire-resistant and does not emit toxic gases when exposed to extreme temperatures. This makes it a safe option for HVAC systems, as it does not contribute to the spread of fires or pose health hazards in case of accidental overheating. Another advantage of fiberglass fabric in extreme temperatures is its durability and long lifespan. It remains intact and unimpaired when subjected to high or low temperatures, making it suitable for prolonged use in HVAC systems. It can withstand the thermal cycling that occurs within the system without compromising its insulation properties or structural integrity. In conclusion, fiberglass fabric is a reliable and efficient material for extreme temperatures in HVAC systems. It offers insulation, energy efficiency, safety, and durability, making it a popular choice for various HVAC applications.

- Fiberglass fabric is available in various thicknesses to cater to different applications and requirements. The most common thicknesses range from 0.5 ounces per square yard (osy) to 3.0 osy. However, it is important to note that the thickness of fiberglass fabric is measured in weight per square yard rather than physical thickness. The thinnest fiberglass fabric options, such as 0.5 osy, are often used in applications where a lightweight and flexible fabric is required. These fabrics are commonly used in industries like aerospace, automotive, and marine, where weight reduction and flexibility are crucial factors. On the other hand, thicker options like 1.5 osy to 3.0 osy are typically used for applications that require higher strength and durability. These fabrics are commonly used in industries like construction, insulation, and industrial manufacturing, where a stronger and more rigid material is necessary. It is worth mentioning that fiberglass fabric can also be customized to suit specific thickness requirements. Manufacturers can tailor the fabric's weight per square yard to meet the desired specifications of a particular project. In conclusion, fiberglass fabric comes in various thicknesses, ranging from 0.5 osy to 3.0 osy, to satisfy different applications' needs. The selection of the appropriate thickness depends on factors such as the desired strength, flexibility, weight reduction, and durability required for the specific project or industry.

- Yes, fiberglass fabric is resistant to UV discoloration. Fiberglass is known for its excellent UV resistance, making it a suitable choice for applications that are exposed to the sun for prolonged periods. The fabric is specifically designed to withstand the damaging effects of ultraviolet radiation, which can cause discoloration and degradation over time. By using fiberglass fabric, you can ensure that your materials will maintain their original color and appearance even when exposed to sunlight for extended periods.

- When working with fiberglass fabric, it is important to take certain safety precautions to protect yourself. Some key measures include wearing protective clothing such as long sleeves, gloves, and safety goggles to prevent direct contact with the skin and eyes. It is also essential to work in a well-ventilated area or use a respirator to avoid inhaling the fiberglass particles, which can cause respiratory irritation. Additionally, using tools with appropriate dust collection systems and cleaning up any loose fiberglass promptly can help minimize the risk of exposure.

- Fiberglass fabric is highly regarded for its impressive performance in terms of tensile strength. Tensile strength refers to a material's ability to withstand tension without breaking or deforming, and fiberglass fabric excels in this aspect. The strength of fiberglass fabric can be attributed to its composition, which consists of finely woven glass fibers. These fibers possess exceptional tensile strength, resulting in a strong and durable fabric. This makes fiberglass fabric ideal for applications that require resistance against pulling forces. Additionally, fiberglass fabric offers a high tensile strength-to-weight ratio, allowing it to withstand substantial amounts of tension without adding excessive weight to the structure. This characteristic is particularly advantageous in industries such as aerospace, automotive, construction, and marine, where lightweight yet sturdy materials are essential. Furthermore, fiberglass fabric maintains its tensile strength even when exposed to harsh environmental conditions, including extreme temperatures, moisture, and chemicals. This reliability makes it a preferred choice for applications that demand stability and longevity. It is important to note that the specific manufacturing process and type of glass fibers used can affect the tensile strength of fiberglass fabric. However, overall, fiberglass fabric is renowned for its exceptional tensile strength performance, making it highly favored in various industries and applications.