High Strength Polyester Woven Geogrids / Biaxial Fiberglass Geogrids

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

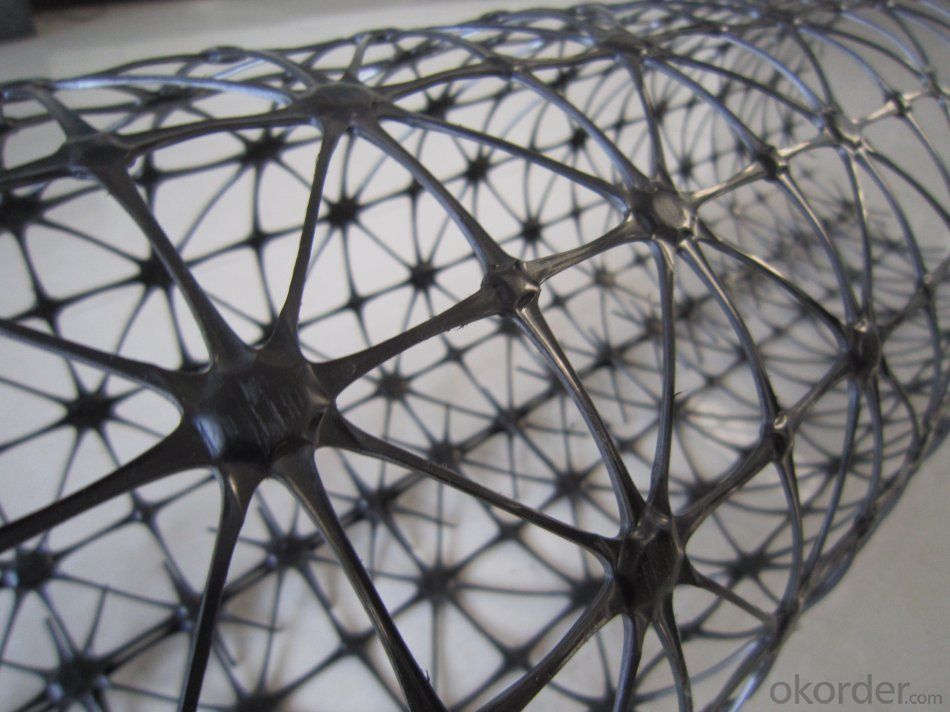

Introduction of PP Biaxial Geogrid:

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geogrids improve the performance of mechanically stabilized slopes in clayey soils?

- Geogrids improve the performance of mechanically stabilized slopes in clayey soils by providing reinforcement and reducing the potential for slope failures. They enhance the tensile strength of the soil, increase its stability, and prevent excessive movement or deformation. This is achieved by distributing the applied loads more evenly throughout the slope, reducing the pressure on the clayey soil, and increasing its resistance to shearing forces.

- Q: Product specifications and performance parameters of glass fiber grating

- The self-adhesive glass fiber geogrid GGA2525 = 25 = 25 = 3 = 312 ~ 501 ~ 6 GGA3030 = 30 = 30 = 3 = 312 ~ 501 ~ 6 GGA4040 = 40 = 40 = 3 = 312 ~ 501 ~ 6 GGA5050 = 50 = 50 = 3 = 312 ~ 501 ~ 6 GGA8080 = 80 = 80 less than 3 = 312 ~ 501 ~ 6 GGA100100 = 100 = 100 = 3 = 312 ~ 501 ~ 6 GGA120170 = 120 = 120 = 3 = 312 ~ 501 ~ 6

- Q: How do geogrids improve the performance of bridge abutments?

- Geogrids improve the performance of bridge abutments by providing reinforcement and stability to the soil surrounding the abutments. They distribute the loads more evenly, preventing soil erosion and reducing settlement. Additionally, geogrids enhance the overall strength and durability of the abutment, allowing it to withstand heavy traffic loads and natural forces such as earthquakes.

- Q: Are geogrids cost-effective?

- Yes, geogrids are cost-effective. They provide long-term stability and reinforcement to soils, reducing the need for extensive excavation and expensive materials. Additionally, geogrids have a longer lifespan compared to other soil stabilization methods, making them a cost-efficient solution in the long run.

- Q: How do geogrids help stabilize soil?

- Geogrids help stabilize soil by providing reinforcement and increasing its load-bearing capacity. They distribute the weight and stress more evenly, preventing soil erosion and potential landslides. Additionally, geogrids enhance drainage and prevent the formation of cracks and settlements, resulting in improved stability and longevity of structures built on the soil.

- Q: How do geogrids enhance the performance of geosynthetic clay liner erosion control blankets?

- Geogrids enhance the performance of geosynthetic clay liner erosion control blankets by providing additional reinforcement and stability to the clay liner. They help distribute the loads more evenly, reduce soil movement, and prevent erosion by reinforcing the liner's tensile strength. This enhances the overall effectiveness and longevity of the erosion control system.

- Q: How do geogrids improve the performance of geosynthetic clay liners?

- Geogrids improve the performance of geosynthetic clay liners by providing added stability and reinforcement. They distribute loads more evenly, reducing the risk of liner deformation and maintaining its integrity. Geogrids also enhance the liner's tensile strength, preventing cracks and enhancing its resistance to shear forces. Overall, geogrids enhance the durability and performance of geosynthetic clay liners, increasing their effectiveness in various civil engineering applications.

- Q: How do geogrids help in reducing the carbon footprint of a project?

- Geogrids help in reducing the carbon footprint of a project by providing a sustainable and environmentally-friendly solution for soil stabilization and reinforcement. By using geogrids, less excavation and material are required, reducing the need for transportation and minimizing energy consumption. Additionally, geogrids can extend the lifespan of infrastructure, reducing the need for frequent repairs and replacements, which further reduces carbon emissions associated with construction.

- Q: How do geogrids help with load distribution?

- Geogrids help with load distribution by providing a reinforced structure that distributes the weight of a load evenly across a larger area. They act as a stabilizing layer within the soil, preventing the lateral movement of particles and reducing the potential for settlement or deformation. This helps to enhance the load-bearing capacity of the soil and prevent localized stress concentrations, ensuring a more uniform distribution of loads and improving the overall stability of the structure.

- Q: How do geogrids improve the performance of geosynthetic drainage systems?

- Geogrids improve the performance of geosynthetic drainage systems by providing structural support and enhancing load distribution. They prevent soil erosion and lateral movement, increasing the stability and longevity of the drainage system. Additionally, geogrids improve the overall drainage capacity by promoting water flow and preventing clogging, ensuring effective water removal from the soil.

Send your message to us

High Strength Polyester Woven Geogrids / Biaxial Fiberglass Geogrids

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords