Fiberglass Fabrics - High Temperature Resistant Acrylic Coated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: The acrylic coated glass fiber cloth overcomes the shortcomings of glass fiber cloth that is not wear-resistant, itchy, and easy to loose yarn after cutting, so that our fire resistant cloth als and performs processing on the glass fiber cloth. It has better wear resistance, easy processing and aesthetic properties. Acrylic coated cloth can withstand higher operating temperatures. Acrylic texture stabilizer with high quality is flame-retardant, low-smoke, temperature resistance of 550 C, feels moderately soft and hard, and has a reasonable cost. Therefore, this coated fabric can be made into welding blanket, insulation covers, fire blanket, fire curtain, fireproof cloth for fire protection. In high temperature operations such as heat preservation, welding protection, fire protection, steel, shipbuilding industry, etc.

Features: Fireproof, Abrasion Resistance, Corrosion Resistance

Application: Fire Blanket, Welding Blanket, Insulation Blanket, Fire Curtain, Welding Curtain, Smoke Curtain, Fire Doors

UNIT: square meter

MOQ: 500 square meters

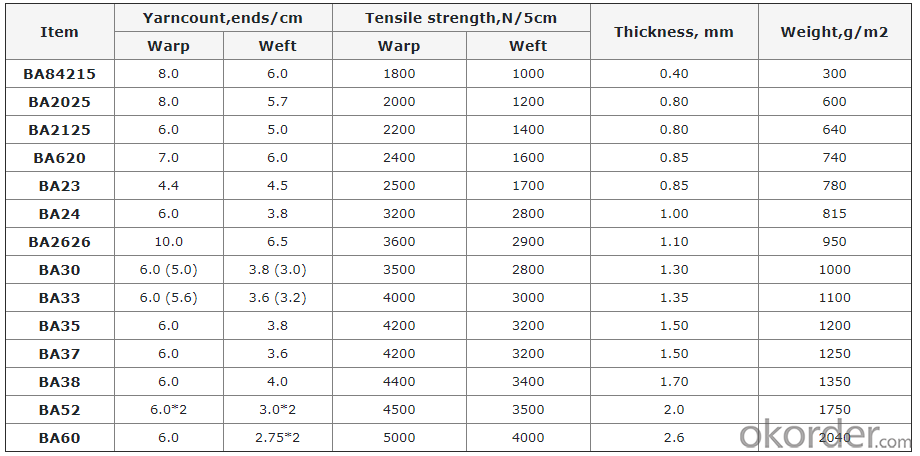

Weight: 140gsm-3000gsm or customized

Width: 1m-2m or customized

Yarn Type: E-glass

Standing temperature: up to 550℃

Product name: Acrylic coated fiberglass fabric

Coating/Finish/Surface Treatment: Acrylic coated

Roll length: 50 meter or customized

Color: Yellow,Black,White,Brown,Blue,Orange,Gray,Salmon,Red or customized

Weave Type: plain woven

Alkali content: alkali free

Processing service: cutting

Material: fiberglass fabric, Acrylic

Thickness: 0.1mm to 3mm or customized

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Acrylic coated fiberglass fabric rolls covered with film packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Can fiberglass fabric be used for heat-resistant gloves?

- Yes, fiberglass fabric can be used for heat-resistant gloves. Fiberglass has excellent thermal resistance properties, making it suitable for applications that require protection against high temperatures.

- Q: How does fiberglass fabric perform in terms of thermal conductivity?

- Fiberglass fabric is known for its excellent thermal insulation properties due to its low thermal conductivity. The fabric is made up of fine fibers of glass, which are highly effective at trapping air pockets. These air pockets act as insulating barriers, reducing the transfer of heat. As a result, fiberglass fabric is capable of resisting heat flow and maintaining a stable temperature, making it an ideal choice for applications requiring thermal insulation, such as in the construction industry, automotive sector, or for manufacturing heat-resistant clothing. Additionally, fiberglass fabric's low thermal conductivity also contributes to its fire resistance, as it does not readily conduct heat to ignite or spread flames. Overall, fiberglass fabric demonstrates superior performance in terms of thermal conductivity, making it a reliable and efficient material for thermal insulation purposes.

- Q: What are the potential health risks associated with handling fiberglass fabric?

- There are several health risks that may arise from handling fiberglass fabric. One major concern is the potential for skin irritation or allergic reactions. The presence of tiny glass fibers in fiberglass fabric can cause skin irritation, resulting in redness, itching, and rashes. Extended or repeated exposure to these fibers can also lead to dermatitis, which is characterized by skin inflammation. In addition to skin irritation, fiberglass fabric can be harmful if it is inhaled. When the fabric is cut, sanded, or disturbed in any way, it releases small fibers into the air. Inhaling these fibers can irritate the respiratory system, leading to coughing, wheezing, and difficulty breathing. Over time, repeated exposure to fiberglass fibers may result in more severe respiratory conditions like bronchitis or even lung cancer. Moreover, the small size of fiberglass fibers makes them challenging to detect and remove from the body once they have been inhaled or come into contact with the skin. This can lead to long-term health risks as these fibers can become lodged in the lungs or other organs, causing chronic inflammation and scarring. To minimize the potential health risks associated with handling fiberglass fabric, it is crucial to take proper precautions. This involves wearing protective clothing, such as gloves, long sleeves, and pants, to prevent direct contact with the skin. Using a respirator or mask can help reduce the inhalation of fiberglass fibers. It is also important to work in a well-ventilated area or use exhaust fans to decrease the concentration of airborne fibers. Regularly cleaning and maintaining workspaces to eliminate any accumulated fibers is also advisable. In conclusion, while fiberglass fabric has various applications and advantages, it is essential to be mindful of the potential health risks associated with its handling. By taking appropriate precautions, individuals can minimize the likelihood of experiencing adverse health effects.

- Q: How is fiberglass fabric used in the production of protective gloves?

- Fiberglass fabric is used in the production of protective gloves as it provides excellent heat resistance and insulation properties. It is often used as a lining material in gloves to protect the wearer from extreme temperatures and potential burns. The fiberglass fabric acts as a barrier, preventing heat transfer and ensuring the safety of the user. Additionally, fiberglass fabric is lightweight and flexible, allowing for comfortable and dexterous glove designs.

- Q: How does fiberglass fabric handle repeated flexing and stretching?

- Fiberglass fabric is known for its exceptional durability and ability to withstand repeated flexing and stretching. Due to its inherent flexibility and high tensile strength, fiberglass fabric can handle these mechanical stresses without significant damage or loss of performance. The interwoven fiberglass strands provide the fabric with excellent resistance to compression, bending, and stretching, making it highly suitable for applications that require repetitive motion or dynamic loads. Additionally, the unique properties of fiberglass, such as its low coefficient of thermal expansion and high resistance to chemicals and moisture, further contribute to its ability to handle repeated flexing and stretching. Overall, fiberglass fabric is a reliable and robust material that can withstand the demands of various industries and applications.

- Q: Can fiberglass fabric be used for insulation in transportation vehicles?

- Yes, fiberglass fabric can be used for insulation in transportation vehicles. It is a commonly used material for its excellent thermal insulation properties, fire resistance, and lightweight nature, making it ideal for insulating the walls, ceilings, and floors of various transportation vehicles such as cars, boats, and aircraft.

- Q: How is fiberglass fabric used in automotive applications?

- Fiberglass fabric is commonly used in automotive applications to reinforce composite materials, such as fiberglass-reinforced plastic (FRP) or carbon fiber-reinforced polymer (CFRP) composites. It is often used in the manufacturing of automotive body panels, interior components, and structural elements. The fabric enhances the strength, durability, and lightweight properties of these composites, making them ideal for various automotive applications. Additionally, fiberglass fabric can help improve the overall safety and crashworthiness of vehicles.

- Q: How to deal with the high temperature fiberglass cloth, so that the trimming can not be scattered

- Stick it with cellophane tape and it won't break in the scissors.

- Q: Can fiberglass fabric be used for reinforcement in chemical processing tanks?

- Yes, fiberglass fabric can be used for reinforcement in chemical processing tanks. Fiberglass is highly resistant to corrosion and can withstand a wide range of chemicals, making it an ideal material for reinforcing tanks in chemical processing industries. It is lightweight, durable, and has excellent mechanical properties, making it suitable for withstanding the harsh conditions of chemical processing.

- Q: What are some popular brands of fiberglass fabric?

- Popular brands such as Owens Corning, 3M, Hexcel Corporation, Saint-Gobain, and Jushi Group are well-regarded for their high-quality fiberglass fabrics. These fabrics find applications across various industries including automotive, aerospace, construction, and marine. Owens Corning, a leading manufacturer, offers a diverse range of fabric options tailored to different needs. 3M, another reputable brand, provides fiberglass fabric known for its excellent thermal resistance and durability. Hexcel Corporation, renowned for its advanced composite materials, offers highly sought-after fiberglass fabrics in the aerospace sector. Saint-Gobain, a global leader in fiberglass fabric production, offers specialty fabrics for multiple industries. The Jushi Group, one of the world's largest fiberglass producers, supplies premium fiberglass fabrics to global markets. These brands are known for their dedication to quality and innovation, making them reliable choices for fiberglass fabric requirements.

Send your message to us

Fiberglass Fabrics - High Temperature Resistant Acrylic Coated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords